Ultra-High-Resolution Optical Coherence Tomography for the investigation of thin multilayered pharmaceutical coatings

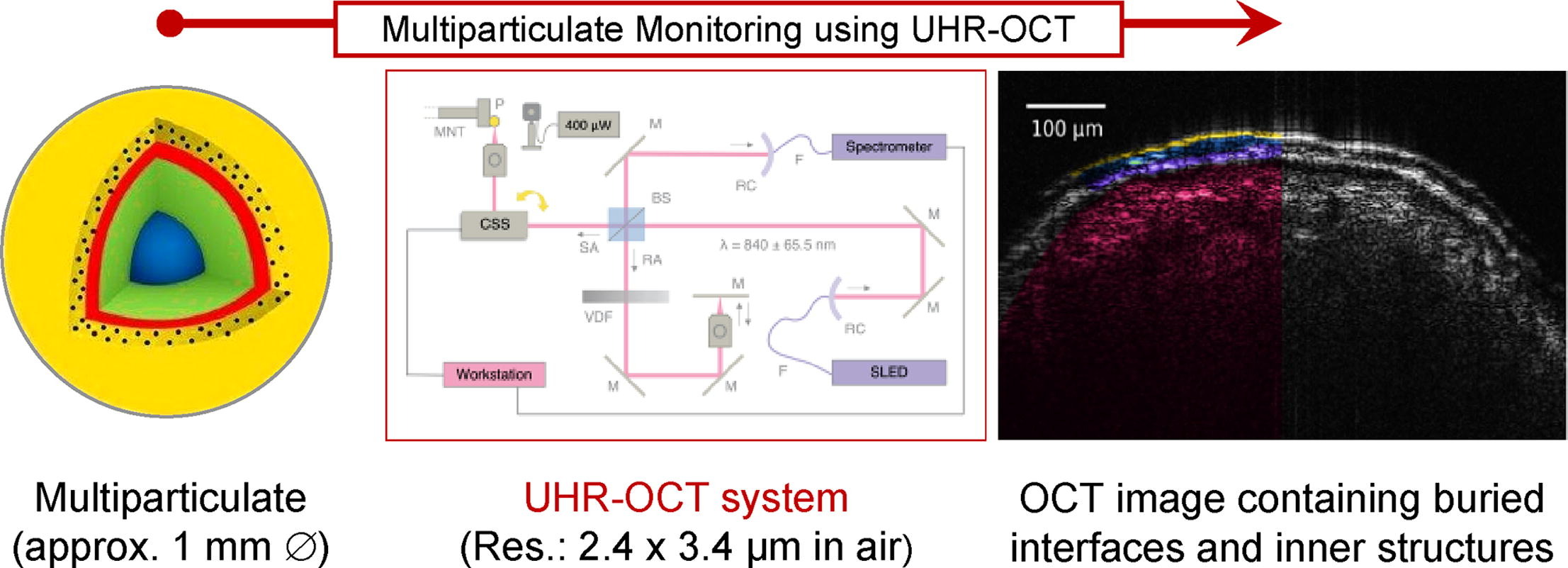

Optical Coherence Tomography (OCT) has recently gained attention as a promising technology for in-line monitoring of pharmaceutical film-coating processes for (single-layered) tablet coatings and end-point detection with commercial systems. An increasing interest in the investigation of multiparticulate dosage forms with mostly multi-layered coatings below 20 µm final film thickness demands advancement in OCT technology for pharmaceutical imaging. We present an ultra-high-resolution (UHR-) OCT and investigate its performance based on three different multiparticulate dosage forms with different layer structures (one single-layered, two multi-layered) with layer thicknesses in a range from 5 to 50 µm. The achieved system resolution of 2.4 µm (axial) and 3.4 µm (lateral, both in air) enables the assessment of defects, film thickness variability and morphological features within the coating, previously unattainable using OCT. Despite the high transverse resolution, the provided depth of field was found sufficient to reach the core region of all dosage forms under test. We further demonstrate an automated segmentation and evaluation of UHR-OCT images for coating thicknesses, where human experts struggle using today’s standard OCT systems.

Introduction

Optical Coherence Tomography (OCT) has been known since the early 1990s and has gained considerable attention in the field of medicine and especially in ophthalmic medical imaging (Drexler et al., 2014; Rainer A. Leitgeb et al., 2021). Due to the remarkable technological development within the past three decades, applications facilitating OCT have spread within a wide field of mostly medical applications (de Boer et al., 2017). Besides the focus on medical imaging, other fields of application evolved within the past decade, such as several applications in non-destructive testing (Alexandra Nemeth, 2013, Kim et al., 2011, Meemon et al., 2013) and in the field of process analytical technologies (PAT) for pharmaceutical coating applications. Recent studies presented several examples of monitoring coating processes using OCT (Korasa and Vrečer, 2018, Wolfgang et al., 2022, 2020). OCT enables the determination of the correct end-point and provides real-time information on the applied film-coatings in pharmaceutical tablet coating processes based on actual coating thickness and coating variability, layer homogeneity, and roughness (Wolfgang et al., 2019). This potentially enables active process control using OCT as real-time PAT (Sacher et al., 2019). However, most studies investigated tablet coatings in a thickness range of above 10 µm up to more than 100 µm for clear, unpigmented functional coatings (Lin et al., 2017). Original OCT data on pellet and multiparticulate coating processes were found to be underrepresented in available literature (Markl et al., 2015, Pietsch et al., 2019). Moreover, the available literature on pellet monitoring by means of OCT investigates only surrogate products (or does not disclose the origin of the samples) with final coating thicknesses in a range between 10 µm and approximately 105 µm for single layers (Li et al., 2014, Pietsch et al., 2019; Wolfgang et al., 2019).

Multiparticulates like coated pellets or beads are of high interest to pharmaceutical scientists since they can satisfy the growing need for advanced dosage forms with tailored release kinetics (Lecomte et al., 2003, Siepmann et al., 2008). Moreover, these solid dosage forms offer the possibility for targeted drug delivery, avoiding systematic absorption, and reducing side effects (Arévalo-Pérez et al., 2020). Coated pellets or beads enable ease of swallowing, efficient taste masking, and the possibility to enhance the bioavailability of active pharmaceutical ingredients (APIs) (Lopes et al., 2017). Further important advantages are the possibility to custom shape dissolution profiles as well as to mitigate the risk of dose dumping and processing advantages with regards to dosing and content uniformity of the final products. (Arévalo-Pérez et al., 2020, Dashevsky and Mohamad, 2006, Porter and Ghebre-Sellassi, 1994).

Modern multiparticulate systems facilitate thinner coating layers compared to the cited showcases investigated with OCT so far. Requests at manufacturers in the pharmaceutical industry resulted in the finding that currently the (in most cases functional) coatings applied to pellets and multiparticulates, have final coating thicknesses in a range of 6 µm to 30 µm (calculated based on weight- or diameter gain). Although the ideal coating thickness is somehow depended on the applied coating composition, it is of paramount importance to meet this targeted value as precise as possible as deviations in coating thickness will directly impact on the resulting release profile (Gaber et al., 2015).

As a consequence of the involved coating processes used for multiparticulate coating and the thin coating thicknesses applied, the currently available OCT systems are of limited use for actual in-line process monitoring. The inherently high particle velocity combined with a small particle diameter poses another challenge for industrial at- or even in-line process monitoring of such thin coated dosage forms. Moreover, the mean particle diameters for multiparticulate systems are expected to be considerably below 1 mm and the elevated particle velocities will require improved spatial and temporal resolution. To summarize, a useful OCT system to monitor multiparticulate coating processes would require technical specifications which are out of reach of industrial OCT systems today.

So far, and to the best of our knowledge, ultra-high-resolution (UHR-) OCT was not previously investigated for its usability to investigate multiparticulate coatings. In 2020, our group introduced a novel OCT light source (Deloria et al., 2020, Haindl et al., 2020b), suitable for UHR-OCT imaging, while maintaining a compact and robust design of 88 mm × 120 mm × 29 mm (Gloor et al., 2019), which is suitable for future industrial applications. In our work, we aim to assess the performance and advantages of a custom designed laboratory UHR-OCT based on the new light source for the investigation of multiparticulate coatings. To cover a broad range of layer thicknesses, product-appearances, and coatings, we investigated three different multiparticulates with single- and multi-layered coating structures.

Read more

Matthias Wolfgang, Alice Kern, Shiyu Deng, Sandra Stranzinger, Mengyang Liu, Wolfgang Drexler, Rainer Leitgeb, Richard Haindl, Ultra-High-Resolution Optical Coherence Tomography for theinvestigation of thin multilayered pharmaceutical coatings, International Journal of Pharmaceutics, 2023, 123096, ISSN 0378-5173,

https://doi.org/10.1016/j.ijpharm.2023.123096.