Tunable Drug Release from Fused Deposition Modelling (FDM) 3D-Printed Tablets Fabricated Using a Novel Extrudable Polymer

Three-dimensional (3D) printing is proving to be a pivotal technology for developing personalized dosage forms with bench to bedside feasibility. Fused deposition modelling (FDM) 3D printing has emerged as the most used technique wherein molten drug-loaded polymer filaments are deposited layer-by-layer to fabricate a predefined shape and internal geometry. However, for precise FDM 3D printing, it is imperative for the filaments to have peculiar mechanical/physicochemical properties, which the majority of the FDA/GRAS approved polymers lack. In the current study, a novel water-soluble polymer, Poly(2-ethyl-tetra-oxazoline) [PETOx] has been investigated as an extrudable and printable polymer with two different types of drug molecule—dextromethorphan hydrobromide (DXM) and hydrochlorothiazide (HCTZ).

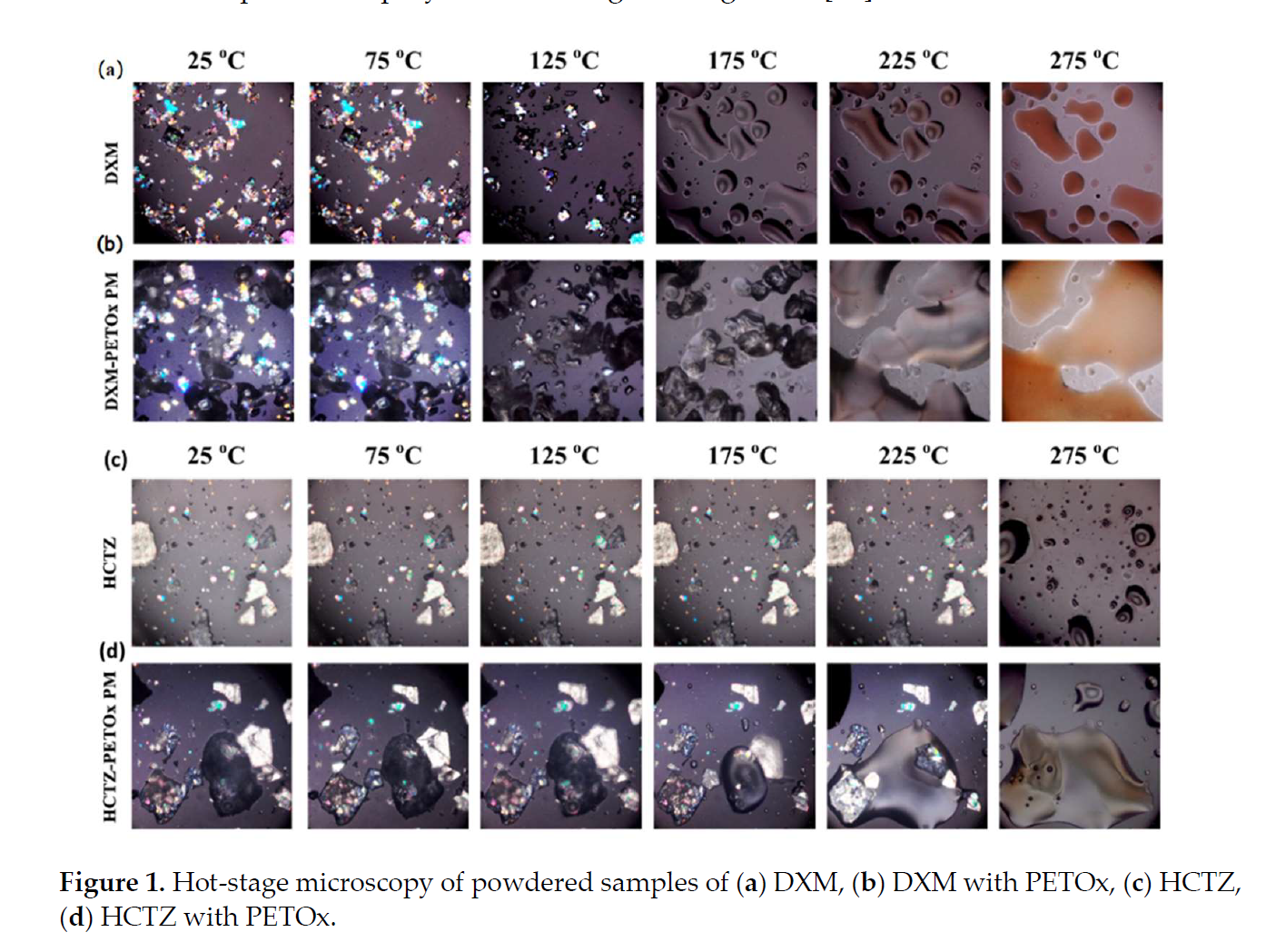

Hot-stage microscopy experiments of drug:polymer (1:1 w/w) and filaments were carried out at 25–275 °C. HCTZ-loaded filament showed higher toughness of 17 ± 3.25 × 106 J/m3 compared with DXM and drug-free filament. Moisture sorption and flexural analysis was performed to understand the correlation of mechanical properties and storage humidity to printability. Varying the number of outer perimeters of each layer (shell number) was observed to affect the drug release pattern from the printlets. The DXM one-shell printlet showed >80%, whereas the DXM five-shell printlet showed >60% of the drug release within 60 min. PETOx could prove to be a high-performance and versatile 3D printable polymer.

Download the research paper as PDF: Tunable Drug Release from Fused Deposition Modelling (FDM) 3D-Printed Tablets Fabricated Using a Novel Extrudable Polymer

Materials

The Dextromethorphan HBr (> 98%) (DXM) was acquired from AK Scientific (Union City, CA, USA), and Hydrochlorothiazide (> 97%) (HCTZ) was acquired from Tokyo Chemical Industry (St. Portland, OR, USA). Poly(2-ethyl-2-oxazoline) (Aquazol®) was kindly gifted by Polymer Chemistry Innovation Inc. (Tucson, AZ, USA). HME Cleaner Plus was used to clean the extruder after experiments were gifted by BioGrund GmBh. Acetonitrile (HPLC grade), Hydrochloric Acid (HCl) were acquired from Fisher Scientific (Hampton, NH, USA).

Raje, V.; Palekar, S.; Banella, S.; Patel, K. Tunable Drug Release from Fused Deposition Modelling (FDM) 3D-Printed Tablets Fabricated Using a Novel Extrudable Polymer. Pharmaceutics 2022, 14, 2192. https://doi.org/10.3390/pharmaceutics14102192

Interest in a sample of HME cleaner plus?