Utilization and Evaluation of Rice Bran and Rice Bran Wax as a Tablet Lubricant

Abstract

Introduction

Lubricants are one of the most important and indispensable excipients that play a pivotal role in the efficient manufacturing of pharmaceutical tablets. During tablet compression, the powder mixture, which typically contains the active ingredient(s), filler/diluents, disintegrants, and binders, among others, is compacted under high pressure, which can result in friction between the tablet surface and the punch surface and die cavities [1]. Without the presence of a lubricant in the formulation, this friction can lead to the sticking and picking of the tablets, which can compromise the quality of the tablet and the efficiency of the manufacturing process [2]. Lubricants help the powder mixture flow smoothly through the compression machine, prevent its adhesion to the surfaces, and reduce the wear and tear of the equipment. They also contribute to ensuring uniformity in tablet weight and hardness, which are important parameters in the quality control of the finished product. Commonly used tablet lubricants include magnesium stearate (MGS), stearate acid, sodium lauryl sulfate (SLS), and poloxamers [3], while glidants and flow enhancers, such as talcum and colloidal silicon dioxide, at suitable specifications and concentrations, were also reported to have lubrication properties [4,5]. However, some of these conventional lubricants possess disadvantages. MGS, for example, can negatively affect the tensile strength, disintegration, and dissolution of tablets, thus compromising the bioavailability and efficacy of the drugs [6,7,8]. Stearic acid can cause the tablets to become sticky and difficult to handle during the manufacturing process. Talcum has a concern over health hazards due to the presence of asbestos fibers in some natural talc deposits, while the role of SLS as a tablet lubricant has recently been questioned, with the experimental data not supporting its use in tablet formulations [9]. Other commercially available pharmaceutical lubricants include sodium stearyl fumarate, glyceryl dibehenate, L-leucine, and hydrogenated plant seed oils. There are also several new tablet lubricants being studied and developed, including alternative metallic stearates, such as sodium and calcium stearates [10] and hexagonal boron nitride [11].

The ever-growing pharmaceutical and nutraceutical industries have seen a steady increase in the use of the currently available excipients, as well as the need for the research and development of new materials to accommodate new processes and to broaden the range of products. With attention being given not only to effectiveness and safety but also to the aspect of environmental sustainability [12], many pharmaceutical and nutraceutical manufacturing companies have currently shown interest in using natural or naturally derived excipients in their production processes. It is therefore important to develop new excipients, including lubricants, based on natural materials to meet such demand.

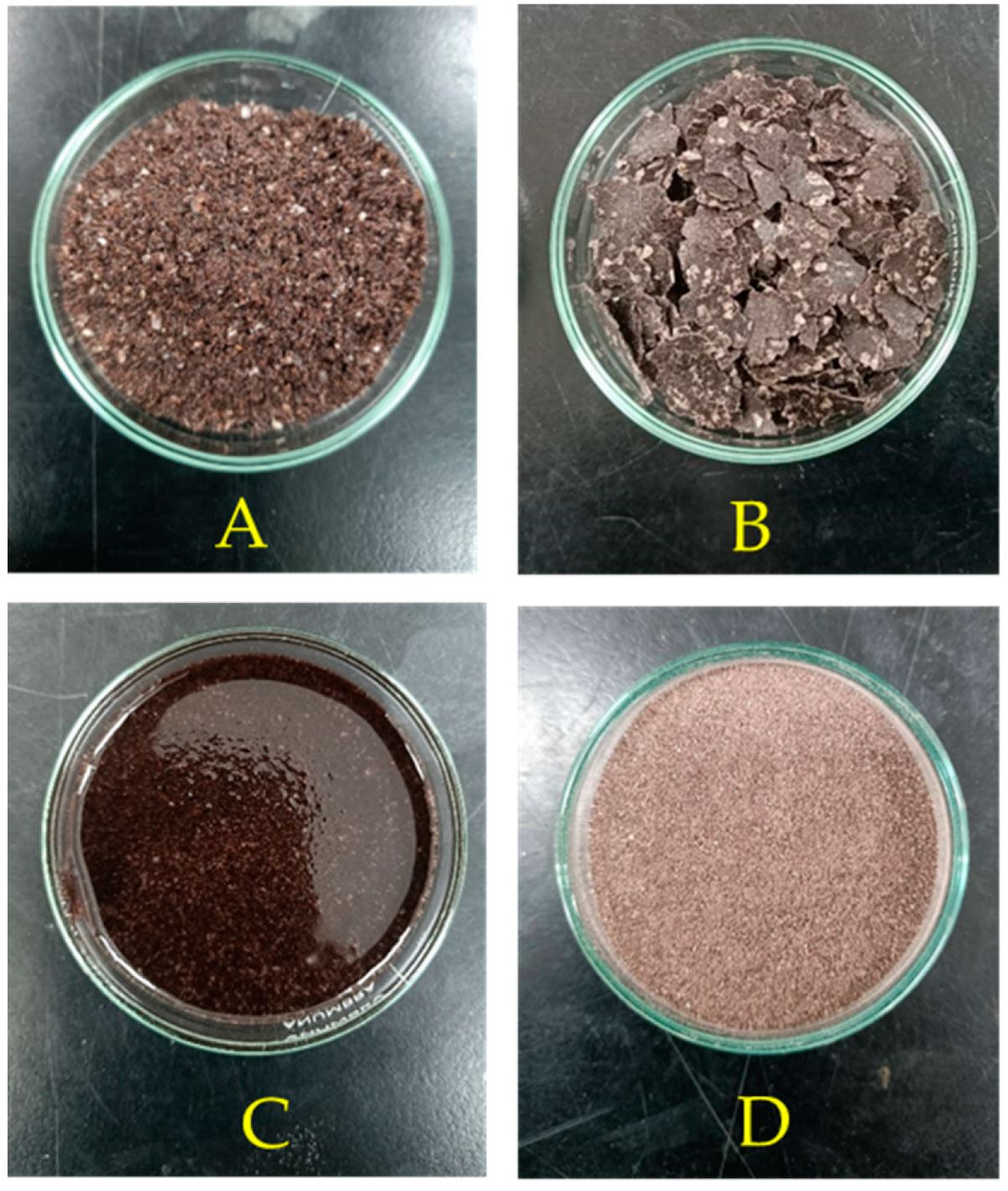

Rice bran is a part of rice grain that is taken off during the rice production process. It generally accounts for 8–10% of paddy weight [13,14,15]. Full-fatted rice bran (FFRB) is composed of carbohydrates (50%), oil (20–25%), and other health-benefited components, such as proteins, minerals, vitamins and derivatives, and dietary fibers. After the oil is extracted, the remaining marc, also known as defatted rice bran (DFRB) or rice bran meal, is usually discarded or sold off to animal farms as feedstock. Several studies have reported on the use of rice bran as an ingredient in animal feed and in human food products, such as cereals, bread, and snacks [16]. It has also been studied for its potential use in various industrial applications, such as in the production of biofuels, bioplastics, and nutraceuticals [17,18,19]. The use of rice starch as a pharmaceutical excipient has long been established. Rice husk, of which the main component is silicon dioxide, has been investigated as a potential glidant and lubricant [20]. Although less studied, rice bran possesses great potential due to its availability, sustainability, nutritional and other beneficial properties, and value-added possibilities [21]. The wax extracted from rice bran (RBW), which is composed of long-chain C22, C24, and C34 fatty acid esters, C18–C34 fatty alcohols, and C16–C26 fatty acids [22], was considered a novel excipient for the pharmaceutical dosage form [23]. It has been employed as an ointment base [24,25] and has successfully been used as a natural lipid composition for solid lipid nanoparticle (SLN) delivery systems [26]. However, neither FFRB nor DFRB have been investigated as tablet excipients, particularly as a lubricant, despite their potential, as suggested by their lipid compositions. This is partly due to the problems of the oxidation and rancidity of the material triggered by endogenous enzymes. To circumvent these problems, the stabilization of rice bran is recommended. Stabilized rice bran (sRB) can be produced by, among many other methods, heating the rice bran materials via microwave treatment [14] or steam sterilization to inactivate the enzymes that play a major role in the rancidity of rice bran due to oxidation [15].

As part of a research study to gauge the potential and optimize the use of rice bran and its compositions as different types of excipients in pharmaceutical formulations, this study investigated the physicochemical properties of the natural and stabilized rice bran samples and isolated rice bran wax as well as their pharmaceutical functionality as tablet lubricants.

Download the full article as PDF here Utilization and Evaluation of Rice Bran and Rice Bran Wax as a Tablet Lubricant

or read it here

Materials

Rice bran of the Khum Jao Mor Chor 107 (KJ CMU107) rice strain was provided by the Lanna Rice Research Center, Chiang Mai University, Chiang Mai, Thailand, in the form of full-fatted rice bran (FFRB) powder. The spray-dried rice starch (SDRS, Era-Tab®) was supplied by the Erawan Pharmaceutical Research and Laboratory (Bangkok, Thailand). The magnesium stearate was from Union Science Chemical (Chiang Mai, Thailand). The hydrogenated cottonseed oil (HVO, Lubritab®) was a product of JRS Pharma (Rosenberg, Germany). A commercial-grade rice bran wax, NatureSoft 860 GMP, was a gift from Micro Powders, Inc. (Tarrytown, NY, USA). All the solvents used in this study were of analytical grade.

Kittipongpatana, O.S.; Trisopon, K.; Wattanaarsakit, P.; Kittipongpatana, N. Utilization and Evaluation of Rice Bran and Rice Bran Wax as a Tablet Lubricant. Pharmaceutics 2024, 16, 428. https://doi.org/10.3390/pharmaceutics16030428

Read also our introduction article on Lubricants here: