Quantitative analysis of wet kneading states by a novel compression test

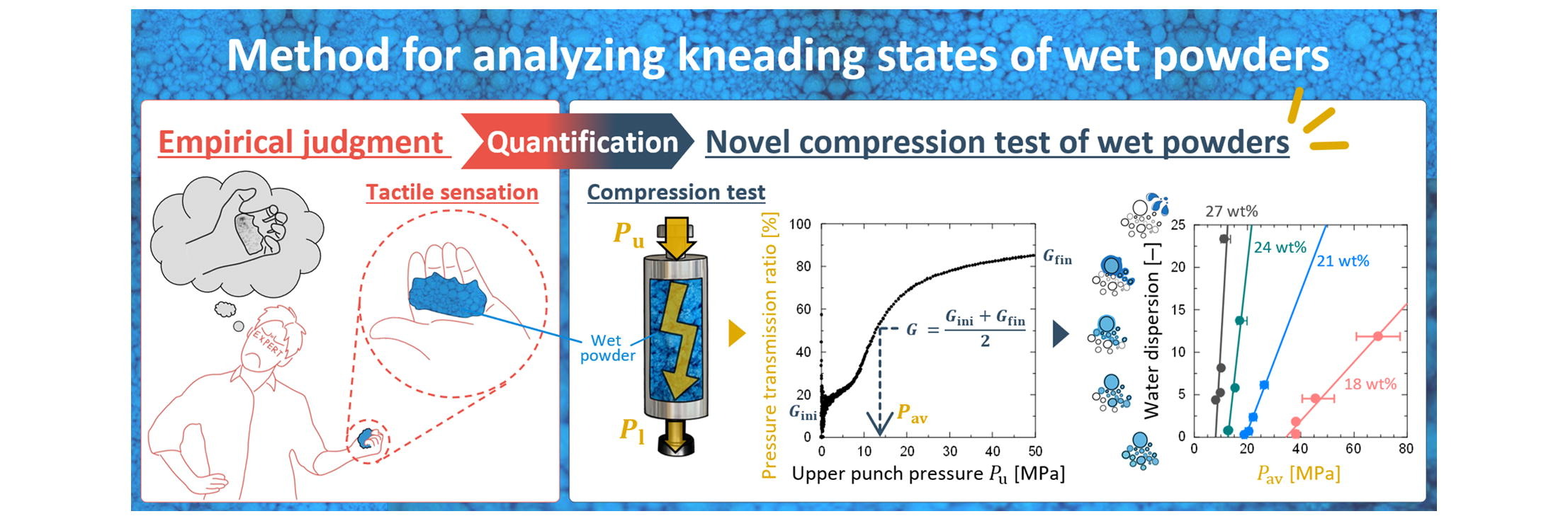

Kneading is a process that mixes powders with liquid to produce homogeneous wet powders, with the process of kneading significantly affecting the quality and productivity of the final product. However, most kneading operations are controlled by the empirical judgment of experts. This study focused on the pressure transmission ratio from the upper to the lower punch during the compression of wet-kneaded powders.

The pressure transmission ratios under various compression and kneading conditions were analyzed to quantitatively understand the kneading state. The results showed that the pressure transmission behavior can be controlled using the ratio of the powder layer height and die diameter as an index. As kneading progressed, the sensitivity of the pressure transmission ratio increased. A quantitative analysis of the kneading state corresponding to changes in water content was successfully conducted using the fitting parameters of the pressure transmission curves.

Read more here

Materials

A pharmaceutical excipient comprising lactose [29] (Pharmatose® 200 M, DFE pharma), corn starch [30] (Nisshoku cornstarch W, Nihon Shokuhin Kako Co., ltd.), and microcrystalline cellulose [30] (CEOLUS® PH-101, Asahi Kasei Corp.) was used. Hydroxypropyl cellulose [31] (HPC-L, Nippon Soda Co., Ltd.) was used as a binder and added in powder form. Table 1 lists the true densities and mass ratios of the raw powder samples, which was prepared to be 100 wt% with powders other than HPC-L (binder).

Jonosuke Matsumoto, Shuji Ohsaki, Hideya Nakamura, Satoru Watano, Quantitative analysis of wet kneading states by a novel compression test, Advanced Powder Technology, Volume 35, Issue 2, 2024, 104336, ISSN 0921-8831, https://doi.org/10.1016/j.apt.2024.104336.

Read more on Binder here: