Film forming systems for topical and transdermal drug delivery

Methyl ester derivatives of alginic acid have been evaluated as potential multifunctional excipients for pharmaceutical direct compression. The use of alginic acid as an excipient in tablet formulation is limited because of certain drawbacks such as low tablet hardness and poor compressibility. The objective of this work is to improve these properties through esterification of alginic acid, chemical modification commonly used for enhancing the functionality of tableting excipients. It has been observed that the degree of methylation (DM) has a profitable impact in the physico-chemical and mechanical properties of the obtained materials. In general, an increase in the degree of methylation yielded tablets with higher tensile strength and better compressibility. Furthermore, modified alginates exhibited extended disintegration times compared to native alginic acid due to the introduced hydrophobicity. Finally, the functional versatility of the modified alginates as disintegrating and filling/binding agents was tested by formulating them with microcrystalline cellulose and lactose. Continue on Film forming systems for topical and transdermal drug delivery – access full publication – open access

The publication contains interesting information on the excipients used in topical and transdermal drug delivery, especially the listing of “Gelling Agents” and “Film Foming Polymers” as listed below.

Gelling Agents

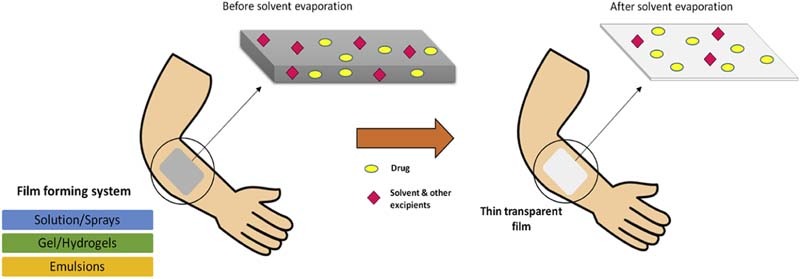

The development of transdermal formulations is being focused on employing several polymers as film forming agents along gelling agents. The administration of film forming gel involves applying a dose on the arms, shoulders, internal parts of the thighs or abdomen to form a thin bioadhesive film on the skin. The drug substance is dissolved in film forming vehicle and is thus incorporated in the film formed on skin. The film can function as an external reservoir or limit the supply of drug substance to the skin thereby controlling the release of drug. Various gelling agents are listed in the following table (based on “Film forming systems for topical and transdermal drug delivery”)

| Gelling agent | Properties |

|---|---|

| Gellan gum | •Anionic polysaccharide •Gel properties depend on the presence of alts •Excellent biocompatibility and degrades into non toxic products |

| Carbomer (Carbopol®) Grades – ETD 2020, 171, 910, 934, 934P, 940, 1342 NF, 1971P | •Excellent gelling efficiency in low concentrations of 0.25% to 1.5% •pH dependent gelling •Forms clear gel in water |

| Carboxymethyl cellulose | •Effective in concentrations of 4 to 6%. •Stable between pH 2 and 10 •Incompatible with ethanol |

| HPMC (E series, F series, K4M, K15M, K100M) | •Effective in concentrations of 2–6% as gelling agent •Produces a smooth, clear spreadable gel |

| Hydroxy ethyl cellulose | •Effective in concentration of 0.5–1% •Has thickening and stabilizing properties |

| Poloxamer (polyethylene–polypropylene glycol co-polymer) Grades – 124, 182, 188, 407 | •Used in the concentrations of 20–30 % •Thermoreversible gelation-liquid at refrigerated conditions and gel at room temperature |

| Sepineo P 600 (acrylamide/sodium acryloyldimethyltaurate copolymer) | •Concentration of 0.5–5% used as gelling agent •It has thickening properties in aqueous or organic media over a wide pH range |

Film Forming Polymers

Polymers are the foundation of the FFS and a variety of polymers are available for the preparation of these systems. In order to achieve the desired film properties, these polymers can be used alone or in combination with other film forming polymers [42]. These polymers should form a clear flexible film at skin temperature. The list of polymers along with their molecular weight and properties are mentioned in this table (based on “Film forming systems for topical and transdermal drug delivery”)

| Polymer | Properties |

|---|---|

| Hydroxypropyl Methylcellulose (HPMC) HPMC (E4M, E15, E50M K4M) | • Produce a light, non-greasy uniform film with good texture • Do not interact significantly with other ingredients • Surface active agent, therefore adsorbs water providing easy dispersion, lubricity and comfort feel in occlusive state on application to skin |

| Ethyl cellulose (EC) | • Nontoxic, nonirritating, nonallergic material • Good film forming properties that form tougher films |

| Hydroxypropyl cellulose | • Nonionic, pH insensitive polymer • Water soluble |

| Polyvinyl pyrrolidine (PVP)(PVP K30, PVP VA64 | • Solubility in water and other solvents • Adhesive and binding property • Acts as a bioavailability enhancer |

| Polyvinyl alcohol (PVA) | • Water soluble • Excellent film forming and adhesive properties • Nontoxic and biocompatible |

| Chitosan | • Excellent film forming ability • Opens the tight junctions of mucosal membrane, thereby enhancing the paracellular permeability and penetration of drug • Controls drug release |

| Eudragit (polymethacrylates copolymer) Eudragit RS 100, RL 100, NE, RS 30D, S 100 | • Transparent, elastic, self-adhesive • Good adhesion to the skin |

| Silicones Polydimethylsiloxane (PDMS) | • Water vapor permeable film • Adequate substantivity and durable film |

| Acrylates copolymer Avalure® AC 118, AC 120 | • Tough, breathable, abrasion resistant films |