Topical Excipients as Pharmaceutical Excipients

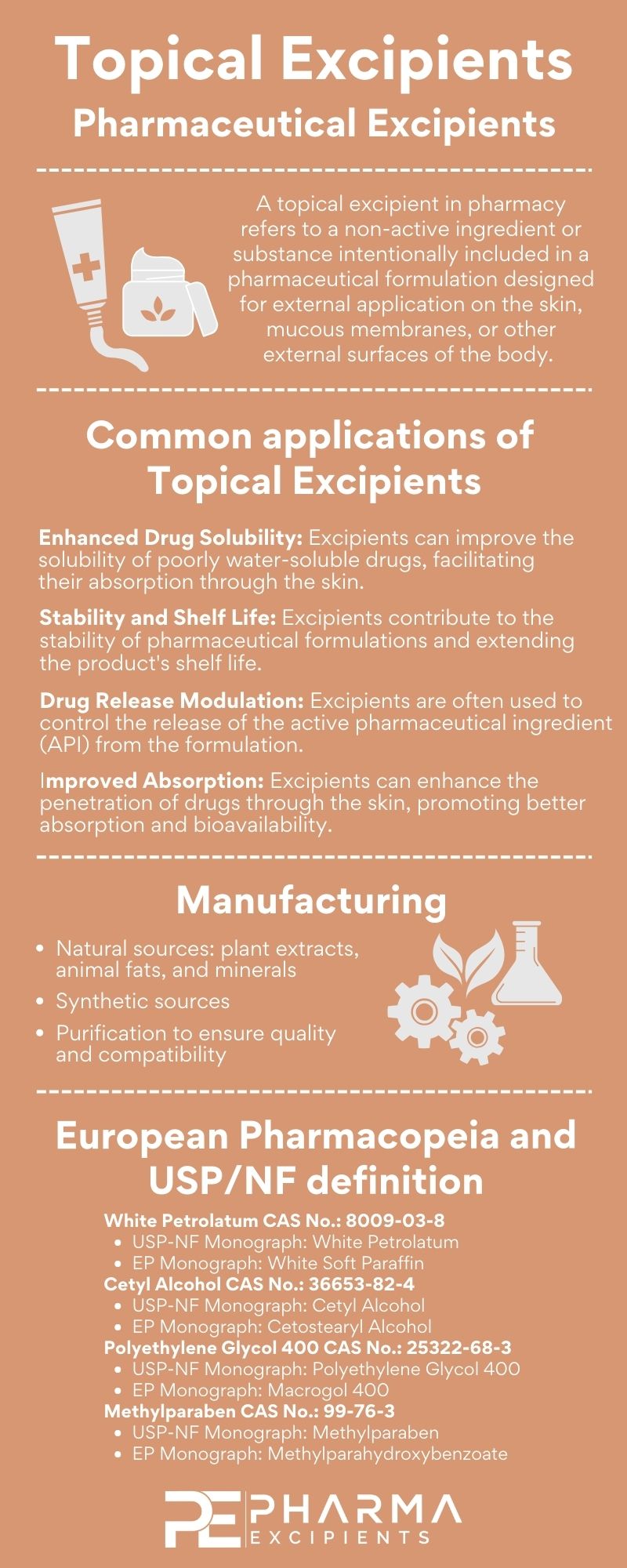

Topical excipients play a crucial role in the formulation of pharmaceutical products intended for external use, such as creams, ointments, gels, and transdermal patches. These excipients serve various purposes, including enhancing drug solubility, ensuring stability, improving drug release, and providing desirable sensory properties. This article delves into the sources, manufacturing processes, and applications of topical excipients in the pharmaceutical industry, along with references to the United States Pharmacopeia-National Formulary (USP-NF) and European Pharmacopoeia (EP) monographs.

Manufacturing of Topical Excipients

Topical excipients are derived from both natural and synthetic sources. Natural sources may include plant extracts, animal fats, and minerals, while synthetic excipients are often produced through chemical synthesis. The manufacturing process involves careful selection and purification to ensure the excipient’s quality, safety, and compatibility with other formulation components.

Common Topical Excipients and their Sources:

- White Petrolatum (CAS No. 8009-03-8):

- Source: Refined petroleum

- Manufacturing Process: Purification through distillation and deodorization

- Purpose: Used as an emollient and occlusive agent in ointments

- Cetyl Alcohol (CAS No. 36653-82-4):

- Source: Fatty acids from coconut or palm oil

- Manufacturing Process: Hydrogenation and purification

- Purpose: Acts as a thickening agent and emollient in creams

- Polyethylene Glycol 400 (CAS No. 25322-68-3):

- Source: Ethylene oxide polymerization

- Manufacturing Process: Polymerization and purification

- Purpose: Serves as a solvent, humectant, and emollient in various formulations

- Methylparaben (CAS No. 99-76-3):

- Source: Synthetically produced

- Manufacturing Process: Esterification of p-hydroxybenzoic acid

- Purpose: Preservative to prevent microbial growth in topical products

Function of Topical Excipients

Topical Excipients play essential roles in pharmaceutical formulations, including:

- Enhanced Drug Solubility: Excipients can improve the solubility of poorly water-soluble drugs, facilitating their absorption through the skin.

- Stability and Shelf Life: Excipients contribute to the stability of pharmaceutical formulations by preventing chemical degradation, oxidation, or microbial contamination, thereby extending the product’s shelf life.

- Drug Release Modulation: Excipients are often used to control the release of the active pharmaceutical ingredient (API) from the formulation. This modulation can impact the duration and rate of drug delivery to the target site.

- Improved Absorption: Excipients can enhance the penetration of drugs through the skin, promoting better absorption and bioavailability.

- Emollient and Occlusive Properties: Emollients, such as fatty acids and alcohols, provide a smooth and soft texture to formulations, enhancing the sensory experience. Occlusive agents, like petrolatum, create a barrier on the skin, preventing water loss and maintaining hydration.

- Thickening and Viscosity Control: Excipients like carbomers, cellulose derivatives, and gums are used to adjust the viscosity of formulations, ensuring easy application and improved stability.

- Humectant Action: Humectants, such as glycerin and propylene glycol, help retain moisture, preventing the drying out of topical formulations and maintaining skin hydration.

- Preservation: Antimicrobial agents, such as parabens, are employed as preservatives to prevent microbial growth and contamination in topical pharmaceutical products.

- Enhanced Spreadability: Excipients like surfactants and emulsifiers improve the spreadability of formulations, ensuring uniform application and distribution of the active ingredients.

- Aesthetic Appeal: Excipients contribute to the overall sensory properties of the formulation, influencing factors such as color, odor, and texture to enhance patient acceptance.

- Compatibility: Excipients are selected to ensure compatibility with the active drug and other formulation components, preventing interactions that may compromise the product’s quality.

- Transdermal Delivery Facilitation: Excipients play a crucial role in transdermal drug delivery systems, aiding in the penetration of drugs through the skin for systemic absorption.

- Targeted Delivery: Excipients can be used in formulations designed for specific skin layers or conditions, allowing targeted delivery of drugs to achieve therapeutic effects.

Factors to consider when selecting Topical Excipients

Selecting topical excipients for pharmaceutical formulations requires careful consideration of various factors to ensure the safety, efficacy, and stability of the final product. Here are key factors to consider when choosing topical excipients:

- Compatibility with Active Ingredients:

- Ensure compatibility with the active pharmaceutical ingredient (API) to maintain its stability and effectiveness.

- Verify that the excipients do not adversely interact with the API, leading to degradation or reduced efficacy.

- Physicochemical Properties:

- Consider the solubility, viscosity, and rheological properties of excipients to achieve the desired formulation characteristics.

- Evaluate the compatibility of excipients with the intended dosage form (e.g., cream, gel, ointment) and route of administration.

- Skin Compatibility:

- Assess the potential for skin irritation, sensitization, or allergic reactions caused by excipients.

- Choose excipients with a proven safety profile for topical use to minimize the risk of adverse skin reactions.

- Penetration Enhancement:

- If required, select excipients that enhance the penetration of the active ingredient through the skin barrier, improving bioavailability.

- Evaluate the impact of penetration enhancers on skin integrity and potential side effects.

- Stability and Shelf Life:

- Consider the stability of the formulation over time, including factors like oxidation, hydrolysis, and microbial contamination.

- Choose excipients that contribute to the stability of both the active ingredient and the overall formulation.

- Cosmetic Characteristics:

- Consider the appearance, texture, and feel of the formulation on the skin to enhance patient acceptability and compliance.

- Ensure that the excipients contribute to a pleasant sensory experience without compromising the therapeutic properties.

- Regulatory Compliance:

- Adhere to regulatory guidelines and pharmacopeial standards for excipients in topical formulations.

- Ensure that selected excipients meet the necessary quality and safety standards for pharmaceutical use.

- Manufacturability:

- Consider the ease of formulation and manufacturing processes when selecting excipients.

- Evaluate the compatibility of excipients with common manufacturing techniques, such as mixing, homogenization, and packaging.

- Cost and Availability:

- Assess the cost-effectiveness of excipients and their availability in the required quantities.

- Consider the economic impact on the overall pharmaceutical formulation without compromising quality.

- Ethical and Cultural Considerations:

- Address any ethical concerns related to the origin or production methods of certain excipients.

- Consider cultural or religious factors that may influence the acceptability of specific excipients.

- Regulatory and Intellectual Property Considerations:

- Ensure that the selected excipients comply with regulatory requirements in the target markets.

- Consider intellectual property concerns related to the use of specific excipients.

By carefully considering these factors, pharmaceutical formulators can develop effective and safe topical formulations that meet both regulatory standards and patient expectations.

Definitions according to the European Pharmacopeia and USP/NF

The United States Pharmacopeia-National Formulary (USP-NF) and the European Pharmacopoeia (EP) have established standards for topical excipients to ensure their quality and safety in pharmaceutical applications.

- White Petrolatum:

- USP-NF Monograph: White Petrolatum (Page 6238, USP 44-NF 39, 2021)

- EP Monograph: White Soft Paraffin (0453, European Pharmacopoeia 10.0, 2021)

- CAS No.: 8009-03-8

- Cetyl Alcohol:

- USP-NF Monograph: Cetyl Alcohol (Page 6002, USP 44-NF 39, 2021)

- EP Monograph: Cetostearyl Alcohol (0438, European Pharmacopoeia 10.0, 2021)

- CAS No.: 36653-82-4

- Polyethylene Glycol 400:

- USP-NF Monograph: Polyethylene Glycol 400 (Page 7128, USP 44-NF 39, 2021)

- EP Monograph: Macrogol 400 (1124, European Pharmacopoeia 10.0, 2021)

- CAS No.: 25322-68-3

- Methylparaben:

- USP-NF Monograph: Methylparaben (Page 3997, USP 44-NF 39, 2021)

- EP Monograph: Methylparahydroxybenzoate (0409, European Pharmacopoeia 10.0, 2021)

- CAS No.: 99-76-3

Topical Excipients

Common Topical Excipients used in the pharmaceutical industry include:

- Emollients: Examples: Mineral oil, petrolatum, fatty alcohols (e.g., cetyl alcohol, stearyl alcohol), fatty acids (e.g., stearic acid), triglycerides

- Emulsifiers: Examples: Cetearyl alcohol, polysorbate 80, sorbitan stearate

- Thickeners and Stabilizers: Examples: Carbomers (e.g. Carbopol® Polymers), cellulose derivatives (e.g., methylcellulose, hydroxyethyl cellulose), xanthan gum

- Humectants: Examples: Glycerin, propylene glycol, sorbitol

- Solvents: Examples: Ethanol, isopropyl alcohol, polyethylene glycols (e.g., PEG 400)

- Preservatives: Examples: Methylparaben, propylparaben, benzalkonium chloride

- Antioxidants: Examples: Ascorbic acid, tocopherols (vitamin E), butylated hydroxytoluene (BHT)

- Surfactants: Examples: Sodium lauryl sulfate, polysorbate 20, lecithin

- Film Formers: Examples: Acrylic polymers (e.g., Eudragit), polyvinylpyrrolidone (PVP)

- pH Adjusters: Examples: Citric acid, sodium hydroxide

- Co-solvents: Examples: Polyethylene glycol (PEG), propylene glycol

- Antimicrobial Agents: Examples: Benzalkonium chloride, chlorhexidine gluconate

- Permeation Enhancers: Examples: Oleic acid, propylene glycol, isopropyl myristate

- Lipid Excipients: Examples: Liposomes, phospholipids, fatty acids

- Colorants: Examples: Iron oxides, titanium dioxide

- Fragrances: Examples: Essential oils, synthetic fragrances

- Gelling Agents: Examples: Sodium carboxymethylcellulose, agar, gelatin

- Buffers: Examples: Phosphate buffers, citrate buffers

- Chelating Agents: Examples: EDTA (ethylenediaminetetraacetic acid)

- Anti-foaming Agents: Examples: Simethicone, silicone oil

Topical Excipients on pharmaexcipients.com – in alphabetical order

| Product | Manufacturer |

|---|---|

| Carbopol® ETD 2020 NF Polymer | Lubrizol |

| Carbopol® Ultrez 10 NF Polymer | Lubrizol |

| Carbopol® 934 NF Polymer | Lubrizol |

| Carbopol® 934P NF Polymer | Lubrizol |

| Carbopol® 940 NF Polymer | Lubrizol |

| Carbopol® 941 NF Polymer | Lubrizol |

| Carbopol® 971P NF Polymer | Lubrizol |

| Labrafac | Gattefosse |

| Lauroglycol | Gattefosse |

| Lauroglycol 90 | Gattefosse |

| Super Refined™ PEG 400 | Croda |

| SUPER REFINED™ POLYSORBATE 80 | Croda |

| Super Refined™ Polysorbate 80 POA | Croda |

| SOFTISAN® 100 | IOI Oleo |

| SOFTISAN® 649 | IOI Oleo |

| SOFTISAN® 601 | IOI Oleo |

| SOFTISAN® 378 | IOI Oleo |

| SOFTISAN® 154 | IOI Oleo |

| SOFTIGEN® 767 | IOI Oleo |

| MIGLYOL® 8810 | IOI Oleo |

| MIGLYOL® 840 | IOI Oleo |

| MIGLYOL® 829 | IOI Oleo |

| MIGLYOL® 812 N | IOI Oleo |

| MIGLYOL® 810 N | IOI Oleo |

| MIGLYOL® 128 | IOI Oleo |

| IMWITOR® 988 | IOI Oleo |

| IMWITOR® 960 K | IOI Oleo |

| IMWITOR® 948 | IOI Oleo |

| IMWITOR® 900 K | IOI Oleo |

| IMWITOR® 900 (F) P | IOI Oleo |

| IMWITOR® 742 | IOI Oleo |

| IMWITOR® 600 | IOI Oleo |

| IMWITOR® 375 | IOI Oleo |

| IMWITOR® 372 | IOI Oleo |

| IMWITOR® 491 | IOI Oleo |

| IMWITOR® 308 | IOI Oleo |