Biochar as a processing additive in poly (butylene adipate-co-terephthalate) (PBAT)

Poly (butylene adipate-co-terephthalate) (PBAT) is a promising alternative to non-biodegradable plastics in agricultural applications. However, it is usually blended with other materials to find a balance of strength, cost, and iodegradability. There is a need to understand the role of additives and fillers that can enhance both performance and biodegradability. Recently, biochar, a material known for its soil amendment qualities, has been proposed as a plastic filler. This study explores the effects and interactions of a commercial wood-based biochar (BC) as an additive within PBAT and compares it to a benchmark made with calcium carbonate (CaCO3), a traditional filler. Mechanical, thermal, rheological, and morphological testing was performed on films manufactured through a blown-film process containing 0.5% weight of additives. Both BC and CaCO3 were found to increase the flexibility and processability without affecting the complex viscosity. The strain at break increased by a factor of 2 and 1.3 for CaCO3 and BC, respectively. On the other hand, CaCO3 increased friction and blocking by factors of 1.7 and 4 respectively, while BC increased friction by a factor of 1.3 without affecting blocking. Moreover, thermal analysis suggests that only BC promotes crystallization. Additional films were prepared where BC initial particle size and loading (5 wt.%) was varied. Changing the particle size showed no significant changes in both tensile strength and rheology, suggesting that additional milling can be obviated. At 5 wt.% BC, lower mechanical properties were observed, but no blocking was detected, and friction was unaffected. An interaction was observed when using both BC (5 wt.%) and CaCO3 (0.5 wt.%) together, improving flexibility and processing properties of PBAT.

Download the full article as a PDF here Biochar as a processing additive in poly(butylene adipate-co-terephthalate) (PBAT)_PDF

Materials

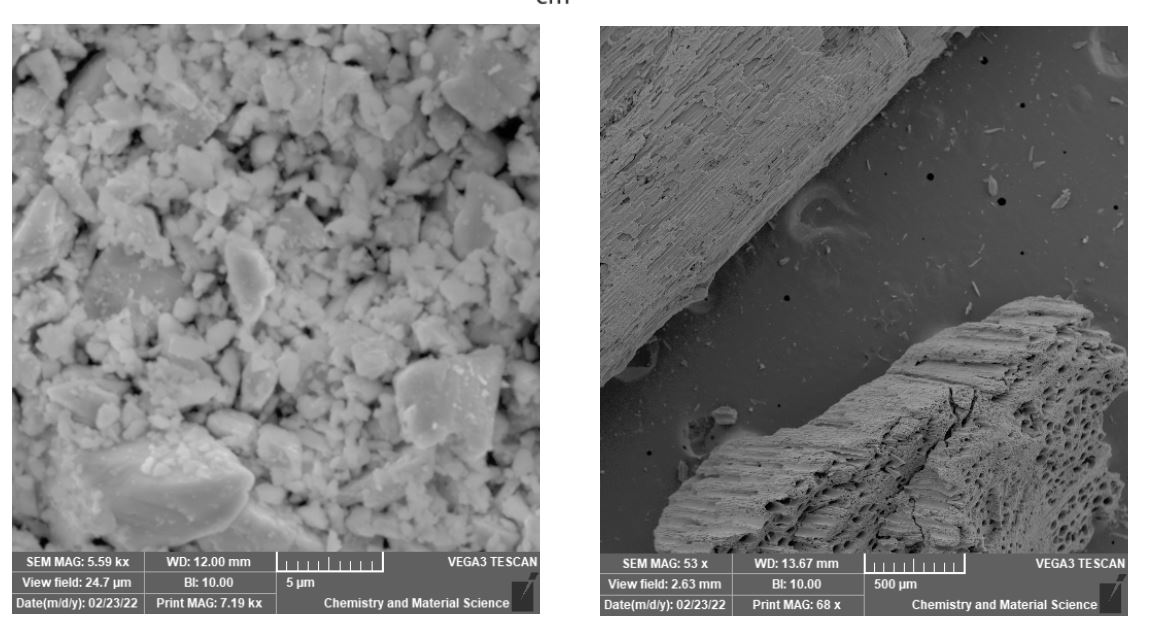

The recycled wood biochar used in this study was supplied from a commercial vendor, Aries Clean Energy (Franklin, Tennessee, USA). It was characterized by Soil Control Lab (Watsonville, California, USA) based on an International Biochar Initiative protocol commonly used for biochar intended for soil amendment applications [34, 35]. The key properties of the biochar for the plastic filling application [21, 24] are shown in Table 1.

The calcium carbonate was supplied by OMYA Inc. (Cincinnati, Ohio, USA), purity reported to be >99.5%. PBAT (EcoWorld®) was supplied by Jinhui Zhaolong High Technology Co. (Shanxi Province, P.R. China) with a melt flow index of 4.8 ± 0.4 g/10min (190°C, 2.16kg).

Source: Y.D. Hernandez-Charpak 1, T.A. Trabold 1, C.L. Lewis 2, C. A. Diaz 3

Golisiano Institute for Sustainability, Rochester Institute of Technology (RIT), Rochester, NY, 14623, USA 2

Department of Manufacturing and Mechanical Engineering Technology, RIT 3

Department of Packaging Science, RIT