Real-time coating thickness measurement and defect recognition of film coated tablets with machine vision and deep learning

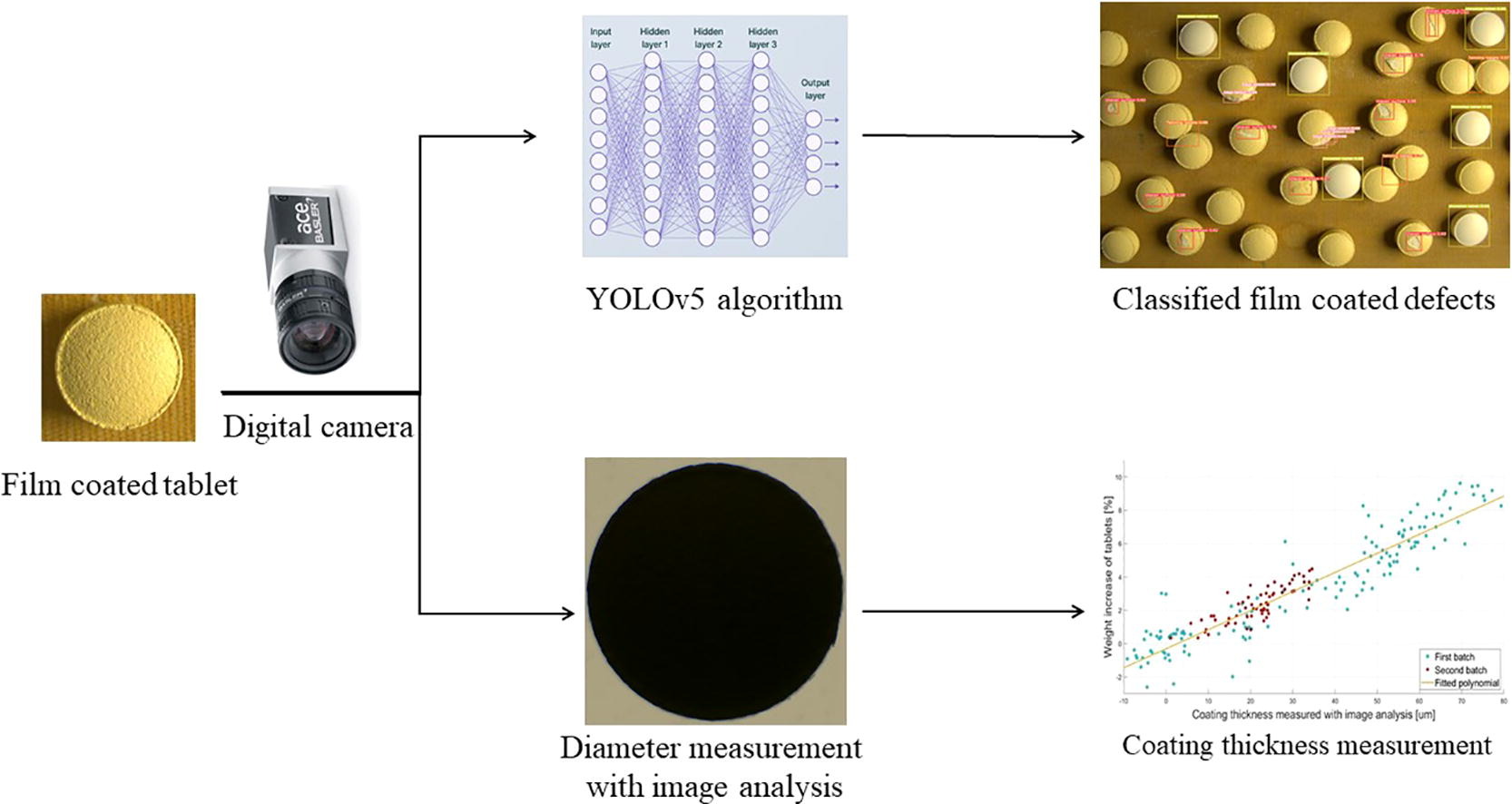

This paper presents a system, where images acquired with a digital camera are coupled with image analysis and deep learning to identify and categorize film coating defects and to measure the film coating thickness of tablets. There were 5 different classes of defective tablets, and the YOLOv5 algorithm was utilized to recognize defects, the accuracy of the classification was 98.2%. In order to characterize coating thickness, the diameter of the tablets in pixels was measured, which was used to measure the coating thickness of the tablets. The proposed system can be easily scaled up to match the production capability of continuous film coaters. With the developed technique, the complete screening of the produced tablets can be achieved in real-time resulting in the improvement of quality control.

Download the full article as a PDF here Real-time coating thickness measurement and defect recognition of film coated tablets with machine vision and deep learning

or read it here

Materials

Avicel PH 302, Microcrystalline cellulose (MCC; Avicel© PH-302) was obtained from FMC Corp. (Philadelphia, Pennsylvania, USA) and magnesium stearate was purchased from Molar Chemicals (Budapest, Hungary). The low viscosity Opadry®QX, a kind gift of Colorcon Inc. (Dartford, UK), was used for coating process.

Máté Ficzere, Lilla Alexandra Mészáros, Nikolett Kállai-Szabó, Andrea Kovács, István Antal, Zsombor Kristóf Nagy, Dorián László Galata,

Real-time coating thickness measurement and defect recognition of film coated tablets with machine vision and deep learning, International Journal of Pharmaceutics, 2022, 121957, ISSN 0378-5173,

https://doi.org/10.1016/j.ijpharm.2022.121957.