Influence of refilling on dosing accuracy of loss-in-weight powder feeders in continuous manufacturing

Abstract

Continuous manufacturing is a novel concept to produce high quality drug products. The manufacture of solid dosage forms starts with the feeding of materials, which is consider a critical step because it could have a high influence on the quality of the final product. Therefore, this unit operation is done by the so-called loss-in-weight feeders developed by various equipment manufacturers to ensure accurate feed rates that allows obtaining products in compliance with the specifications. Nonetheless, as the feed hopper of a feeder is of limited capacity, it must be refilled on regular basis to maintain continuous manufacturing. During refilling, dosing must be done in volumetric mode which can have an impact on dosing accuracy.

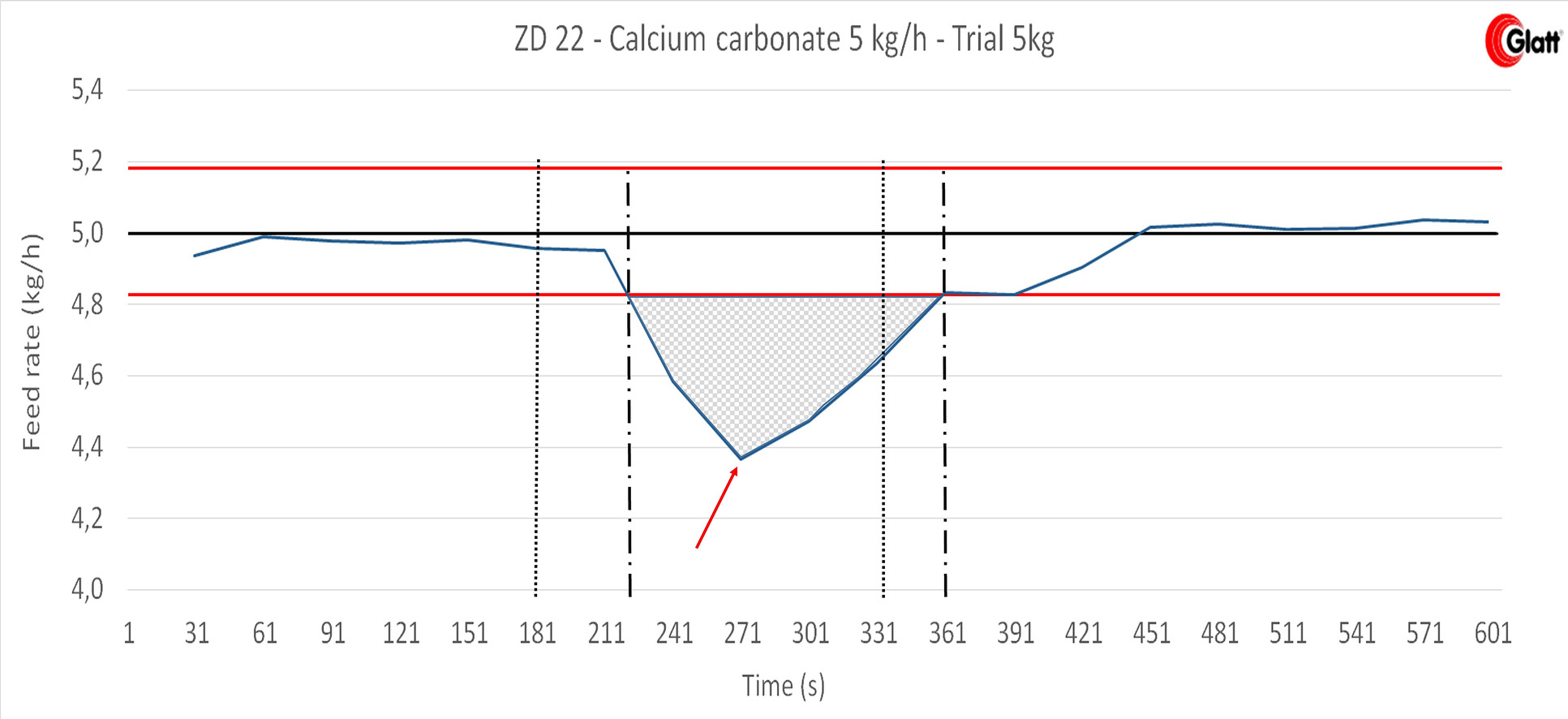

The present work studies the impact of the refill and different factors such as the feed rate, the refill system and the filling level at which the refill starts on the accuracy of the dose. Four performance indicators were used to evaluate this impact: the refilling time, the time out of the limits, the maximum or minimum feed rate during the refilling and the total deviation from the set point.

The refiller type and the filling level at which the refill starts play an important role and should be selected considering to the material’s characteristics to be fed. As a general rule, a faster and shorter refill is always preferable, however, depending on the refiller type and the material, a positive or negative deviation from the feeding dose can be observed.

Introduction

Pharmaceutical oral dosage forms have been produced for the last decades in the pharmaceutical industry by using the batch concept in which all materials are charged into the equipment before starting the production and discharging at the end. In this concept the different unit operations required to produce the final product are performed one after the other, where a certain amount of material is processed in a predefined time.

However, lately more pharmaceutical industries are developing new products under the continuous manufacturing concept which is characterized and differs from the batch concept by two main differences.

First, a small amount of material is processed per time; however, this material is flowing through the different unit operations continuously at certain speed to achieve the desired outcome.

The second difference is that the intermediate material and the final products are analyzed on-line and/or in-line by using process analytical technologies (PAT) for monitoring and controlling [1]. PAT tools help ensuring the detectability of the disturbances within the process, accurately sort the non-compliant material, and release the batch with real-time testing avoiding the time required for release analysis [2].

Food, consume or chemical industries have already implemented the continuous manufacturing successfully since decades but pharmaceutical industries being a highly regulated industry is just recently slowly beginning to benefit from its advantages. When producing pharmaceutical dosage forms less scale-up problems can be faced, real-time tests and release, tighter controlled processes, shorter storage times, therefore, the quality and profits are increased are some of these advantages [3].

In continuous manufacturing the first unit operation in the manufacture of pharmaceutical oral dosage forms, is the feeding of the raw materials. Loss-in-weight (LIW) feeders are used for this means and are expected to run non-stop during long period of time. Small variations can be corrected by the dry mixer downstream. However, if the feeder is not able to accurate dose at the target feed rate, variability not only in the downstream process but also at the end in the final product may be expected since this will define the content of the API and materials in the formulation [4,5].

Feeders for continuous manufacturing can operate in two different modes: volumetric and gravimetric [1]. During volumetric mode the raw materials are fed by maintaining a constant speed of the screws and can be described by the following equation: m =pbulk∗V

Nevertheless, this is not the preferable operation mode as it is prone to variations over time due to a high influence of the material density.

The gravimetric mode known also as “loss-in-weight” displays more accuracy since is not density dependent. In order to determine the amount of material loss per time, the feeder is placed over a load cell connected to a control box which monitors in real time the material lost per unit of time. In this mode the loss-in-weight is measured and compared with the one set by the user.

The feeding rate is then calculated by the following equation.

The deviation of the actual value with the set point is calculated and the feedback is sent to the controller to feed more or less material by speeding the screws up or down as required. The faster the screws turn, the higher the flow rate.

In Fig. 1 a schematic representation of the weighing process is depicted. It can be observed that while the feeding process takes place, the filling level of the hopper decreases and, to maintain a continuous manufacturing, the material should be replaced by refilling the hopper when the lowest level suggested by the manufacturer is achieved. During the gravimetric feeding the screws are running according to the feed factor which can be defined as the amount of material dispensed per revolution of the screws (g/rev) [6], however, during refilling the feeder is not capable of controlling the feeding rate based on the loss-in-weight mode because the equipment is gaining weight rather than losing it and therefore, while the refilling is taking place the feeder should enter into volumetric mode where the screws run at certain speed, which is either the last screw speed registered by the feeder before going into volumetric mode or the speed calculate by using the feed factor as a reference. This way the feeding process continues and diminish interruptions which might lead to deviations from the set point.

The degree of these deviations will depend on several factors for example, the refilling time which is the time that the equipment operates in volumetric mode, the hopper filling level at which the refilling starts due to change in density of the material and the refiller type, among others.

The shorter the time the feeder spends in volumetric mode the better for the dose accuracy and therefore, the investigation of the best refilling system for each material is of great importance, because the different material properties might have an influence on the refilling type to be used, therefore the objective of this research was to determine the influence of the refilling in the dose accuracy of low in weight feeders by determining the impact of different factors such as refiller type, filling level at which the refill starts and the feed rate to be used.

There are five main components of a feeder:

- Weighing device and controller

- Dosing module

- Dosing hopper

- Refilling system

The first two components of a feeder are working together: the weighing device and the controller. What differentiate a LIW feeder from a volumetric feeder is the possibility to measure the amount of material lost per time and this is done with the weighing device. There are two types of them: the digital and analog device. When a digital unit is used, the digital weight value is sent through the circuits to the controller [7]. On the other hand, the analog unit uses as it names says an analog signal usually a voltage which is a representation of the weight, this signal should be transformed to be analyzed. A strain-gauge load cell is a sensor for force measurement which converts the kinetic energy of a force into an electric signal that be measure and is the most common analog weighing device used in LIW feeder [8], this information is sent to the controller which uses a control algorithm that calculates an error value and reacts accordingly to regulate the process variable minimizing the error and get closer to the target value [9].

The dosing module is integrated by two mechanical parts: the conveying system (screws) and the flow aid mechanical unit (agitator). The conveying system delivers the material into the downstream process, the selection of the screw types depends on the characteristics of the materials. The agitator is useful to promote the homogenous dispersion of the material in the hopper and arrangement inside the screws. The agitator is also helpful to avoid bridging in case of cohesive material [10].

The dosing hopper is also called the weighed hopper is where the material to be fed is contained. [11]. Nowadays exists different hopper shapes, round or flat tray bottom, being this last one the most common one due to the easy handling and fast cleaning.

Another important part to consider while thinking of the design of the LIW is the hopper capacity as this has a direct influence on the refilling and therefore should be designed according to the material’s characteristics and the feed rate required for the process. By selecting the appropriate hopper size, the disturbances derived from the refilling process can be minimized. If the hopper is big enough, then the number of refills per hour can be reduced; on the other side when the hopper is too small, the number of refills increases proportionally [12].

The last component of a feeder is the refilling system. It has been previously mentioned that when a minimum level is reached, the refilling takes place which is usually done from a larger hopper or storage container placed above the weighed hopper. This storage container is charged by using pneumatic transport. Once the storage container is full, a refilling system is needed to transfer the material from the container above to the weighing hopper. Currently there are several options available in the market to do so. This can be achieved by modulating butterfly valves, rotary valves, knife gates or pneumatic transport among others depending on the process requirements.

The different refilling systems can minimize the deviation from the set point while refilling if the material properties are taken into consideration. For heavier materials a butterfly valve or knife gates will not be adequate if the opening cannot be modulated according to the material flow and therefore, a large amount of powder will enter the weighed hopper that may change the density of the powder in the screws increasing the deviation during the volumetric mode. In that case a modulating butterfly valve would be a better option to have a smoother refill.

In contrast with heavy materials, powders of low density might be more suitable to be fed using a faster refilling system like a butterfly valve to avoid prolonged times in volumetric mode. Special considerations should be taken when feeding materials with poor flowability or cohesive powders as these tend to agglomerate or stick in the vanes of the rotary valves which may lead to disturbances if they fall into the hopper once the gravimetric mode is active again [13].

Hence, the investigation of the different mechanical factors and process parameters that can impact significantly during the refill is of great importance to achieve a highly accurate feeding process through all time.

Read more here

Fabiola N. Santamaría Alvarez, Peter Kleinebudde, Jochen Thies, Influence of refilling on dosing accuracy of loss-in-weight powder feeders in continuous manufacturing, Powder Technology, 2024, 119501, ISSN 0032-5910, https://doi.org/10.1016/j.powtec.2024.119501.