Recent advances of electrospray technique for multiparticulate preparation: Drug delivery applications

Abstract

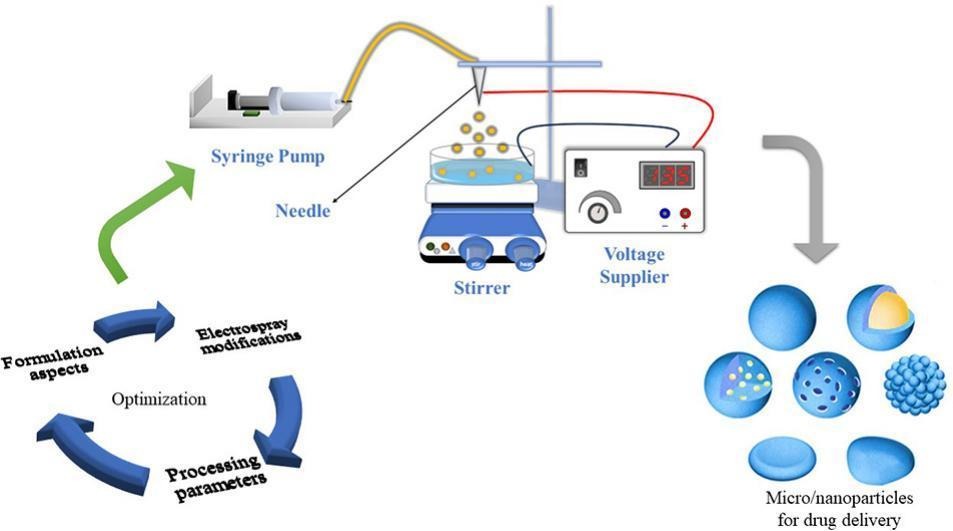

The electrospray (ES) technique has proven to be an effective and a versatile approach for crafting drug delivery carriers with diverse dimensions, multiple layers, and varying morphologies. Achieving the desired particle properties necessitates careful optimization of various experimental parameters. This review delves into the most prevalent ES system configurations employed for this purpose, such as monoaxial, coaxial, triaxial, and multi-needle setups with solid or liquid collector.

In addition, this work underscores the significance of ES in drug delivery carriers and its remarkable ability to encapsulate a wide spectrum of therapeutic agents, including drugs, nucleic acids, proteins, genes and cells. Depth examination of the critical parameters governing the ES process, including the choice of polymer, surface tension, voltage settings, needle size, flow rate, collector types, and the collector distance was conducted with highlighting on their implications on particle characteristics, encompassing morphology, size distribution, and drug encapsulation efficiency. These insights illuminate ES’s adaptability in customizing drug delivery systems. To conclude, this review discusses ES process optimization strategies, advantages, limitations and future directions, providing valuable guidance for researchers and practitioners navigating the dynamic landscape of modern drug delivery systems.

Introduction

The term “drug delivery systems” (DDS) encompass drug carriers that carry active agents to specific tissues, organs, cells, and organelles for modulated drug release and absorption [1]. Therapeutic treatment aims for greater efficacy by delivering drugs in a sustained, site-specific manner, maintaining therapeutic concentrations at the target biological site. Conventional medication delivery strategies suffer from systemic toxicity and repeated dose issues [2]. Therefore, traditional tablet and liquid oral dosage forms have evolved into innovative drug delivery systems (DDS), including nanoparticulate, microparticulate, microbeads, and bead-based DDS. These tiny carriers have been extensively employed due to their considerable advantages over traditional dosage formulations. These advantages encompass reduced potential for systemic toxicity and local irritation, a consistent rate of gastric emptying, decreased variability in absorption profiles, enhanced bioavailability with minimal fluctuations in drug plasma levels, precise and site-specific drug delivery, and diminished side effects [1,3,4].

Numerous researchers have pioneered various methods for generating small particles within the realm of DDS. These techniques include ionic gelation, high-heat processes, homogenization, electrospray (ES), spray drying, among others [5,6]. Significantly, there has been a recent upsurge in the adoption of both natural and synthetic polymers, such as arginine, chitosan, polyethylene glycol, poly(glycolic acid), poly(α-hydroxyesters), and poly(lactic acid), for use as encapsulation materials in numerous drug delivery systems (DDS) [7,8]. Polymer-based drug delivery systems are pivotal in serving as carriers for the controlled release of a wide spectrum of active substances, including anticancer agents, antidiabetics, immunomodulatory agents, nucleic acids, and proteins. The selection of these polymers is primarily driven by their commendable attributes of biocompatibility, biodegradability, and bioreducibility [9]. The concept of drug delivery via polymeric carriers lies in the fundamental principle that an increased surface area of the drug carrier enhances the drug-dissolution rate. Various techniques and methods have been employed to prepare carrier systems tailored for the specific purpose of drug delivery [7].

Electrohydrodynamic (EHD) techniques involve the use of electrostatic forces to create nano to macro-sized fibers or particles through the manipulation of an electrically charged fluid jet. Through various methods like blending, surface modification, and coaxial processes, it is feasible to integrate bioactive molecules such as drugs, proteins, cells, DNA, and growth factors into the carriers produced using EHD techniques. Careful selection of materials and processing conditions allows for the attainment of desired encapsulation efficiency and the preservation of bioactivity in therapeutic agents. EHD techniques include electrospinning and electrospraying, which are employed for producing continuous ultrafine fibers and particles, respectively [10,11]. Electrospinning is the most widely adopted method for nanofiber fabrication, thanks to its simplicity, flexibility, scalability, the ability to spin various polymers and cost-effectiveness. This technique allows for the direct encapsulation of drugs into the resulting nanofibers. Applications of drug-loaded nanofibrous membranes range from topical use in skin care, wound healing to postoperative implants for antibiotic, antifungal, antimicrobial, and anticancer drug delivery [12]. On the other hand, electrospraying, also known as electrohydrodynamic atomization (EHDA), is a modified version of the electrospinning process [13]. It shows promise for generating macro, micro- and nanoparticles suitable for use in drug-delivery systems. These polymeric carriers can be administered through various routes, including oral, topical, inhalable and local drug delivery [14].

Traditional emulsification techniques and coacervation approaches exhibit certain drawbacks, including prolonged processing times, suboptimal drug entrapment levels, and extensive utilization of organic solvents or surfactants. These limitations significantly restrict their potential applications. In contrast, electrospraying technique effectively circumvents these issues while also allowing for the customization of carriers to match the properties of specific drug. Additionally, it encourages innovative solutions to reduce the consumption of high-energy resources, waste generation, emissions, and associated risks. Consequently, ES has undergone extensive research and practical utilization since its emergence in 1914 [9].

The ES method has also been effectively employed in the development of targeted therapeutic delivery systems through the encapsulation of drugs within appropriate carriers. In addition to single-drug encapsulation, ES has been utilized for the encapsulation of two or more therapeutic agents within multi-layered polymer matrices, facilitating controlled release and targeted delivery [15]. The fundamental objective of regulating drug release is to mitigate the risks of both under-dose and over-dose, ultimately enhancing the efficacy of therapeutic treatments. Controlled-delivery systems, furthermore, can uphold drug levels within the desired therapeutic range, reduce dosing frequency, enhance the stability of encapsulated substances against enzymatic degradation, diminish toxicity, and promote better patient adherence [16]. Number of researchers have explored the combination of electrospinning and electrospraying to develop fibers loaded with electrosprayed particles containing a therapeutic component [17,18].

The objective of this study is to provide a comprehensive review of recent progress, adaptations, constraints, and applications of the ES technique in the realm of drug delivery. In addition to the primary focus on the utilization of ES in the pharmaceutical industry, this review will also explore recent modifications and enhancements made to the ES technique, as well as the latest polymers used in drug delivery systems. Furthermore, it will delve into the processing and formulation parameters that have a significant effect on the ES process and how these parameters can be optimized to tailor drug delivery systems for improved therapeutic outcomes. The goal is to provide readers with a thorough understanding of the most recent developments in ES technology and its potential for advancing drug delivery applications while addressing the key factors influencing its effectiveness.

Read more here

Mulham Alfatama, Yasser Shahzad, Hazem Choukaife, Recent advances of electrospray technique for multiparticulate preparation: Drug delivery applications, Advances in Colloid and Interface Science, Volume 325, 2024, 103098, ISSN 0001-8686, https://doi.org/10.1016/j.cis.2024.103098.

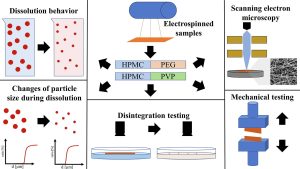

Read more on Electrospinning here:

- Oral fast-dissolving risperidone loaded electrospun nanofiber drug delivery systems for antipsychotic therapy

- Desloratadine-Loaded Flexible Orally Dissolvable Tablets Made of Electrospun Fiber Mats

- The Impact of Polymer Mixture Composition on the Properties of Electrospun Membranes for Drug Delivery Applications