Effect of particle characteristics and foaming parameters on resulting foam quality and stability

In this study, the effects of ten different food-grade particles on bubble quality and stabilization of particle-stabilized food foams in batch and continuous foaming with and without polyglycerol ester (PGE) as an emulsifier were investigated. Particle properties, such as contact angle and porosity, and varying process parameters, such as shear rate and gas fraction, were assessed with respect to their impact on bubble size x50,0, bubble size distribution width and drainage.

Highlights

- Use of particles without emulsifier reduced median bubble size and improved foam stability.

- Combining PGE emulsifier and particles resulted in higher foam stability.

- Particularly low drainage was observed in particle stabilized foams using banana powder.

- Increases in particle size and wetting angle correlated with reduced drainage.

- High shear rates were strongly associated with narrower bubble size distributions.

The smallest bubble size x50,0 in foams without PGE could be achieved with banana powder (88 μm), calcium carbonate (89 μm) and microcrystalline cellulose (79 μm) particles. In comparison, the smallest size in the reference without particles were 105 μm. Combining the use of particles with PGE further reduced bubble size by up to 57% and drainage by up to 100%. Increasing the shear rate from 4922 s−1 (35 μm) to 9844 s−1 (14 μm) resulted in smaller mean bubble sizes and significantly narrower bubble size distributions whereas no distinct correlation between gas fraction and resulting bubble size was found.

This study shows that using suitable particles in combination with an optimized foaming process promotes both bubble quality and the stability of foams.

Download the full article as PDF here Effect of particle characteristics and foaming parameters on resulting foam quality and stability

or read it here

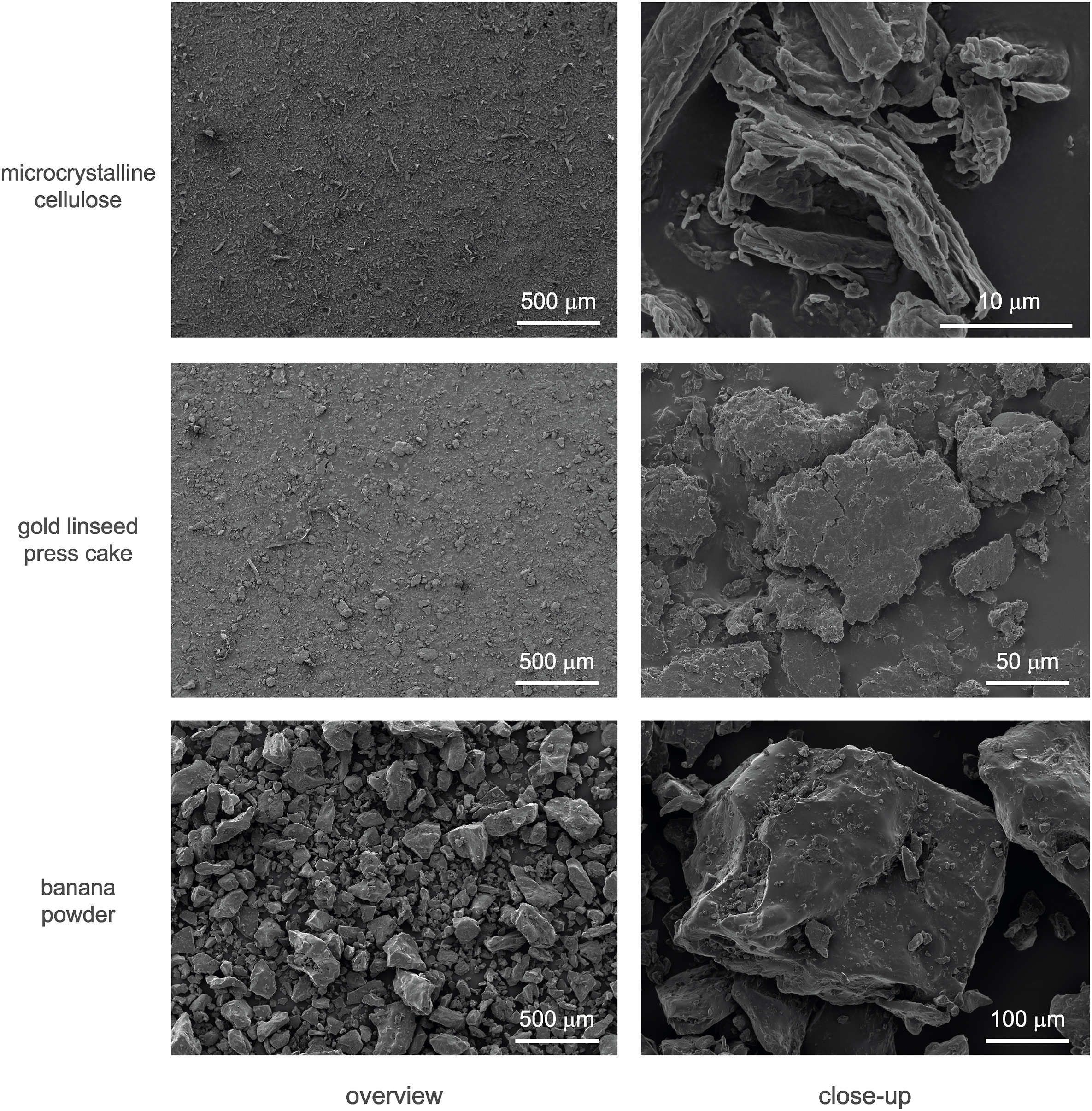

Foaming for particle screening

For particle screening purposes, the following particles were examined in the basic suspension, both with and without PGE: silicic acid (Kieselsäure Lebensmittelqualität, Armonia GmbH, Switzerland), oil press cake from golden linseed (Bio Goldlein Presskuchen, Goldmühle GmbH, Switzerland), oil press cake from sunflower seeds (Bio Sonnenblumen Presskuchen, Goldmühle GmbH, Switzerland), soy protein isolate (Soya Protein Isolate 100% unflavoured, bulk, UK), microcrystalline cellulose (Microcrystalline Cellulose, J. Rettenmaier & Söhne, Germany), banana powder (Bananenfruchtpulver, Spiceworld GmbH, Austria), pea protein isolate (Super Pea Protein Isolate, bulk, UK), calcium carbonate (Calcipur 110 KP, Omya AG, Switzerland), soy granulate (Vantastic Foods Soja Granulat, hellovegan, Switzerland) and chicken egg white (Egg White Powder, bulk, UK).

600g of the basic suspension was whisked in a kitchen foaming machine (Hob-N50 Universal food processor, Hobart) for 4 min at the highest rotational speed (agitator = 580 rpm). The foamed basic suspensions with (Ref_PGE) and without PGE (Ref_w) were prepared and served as reference foams. All experiments were carried out in duplicate.

Ramona Rüegg, Tamara Schmid, Lukas Hollenstein, Nadina Müller,

Effect of particle characteristics and foaming parameters on resulting foam quality and stability, LWT, Volume 167, 2022, 113859, ISSN 0023-6438, https://doi.org/10.1016/j.lwt.2022.113859.