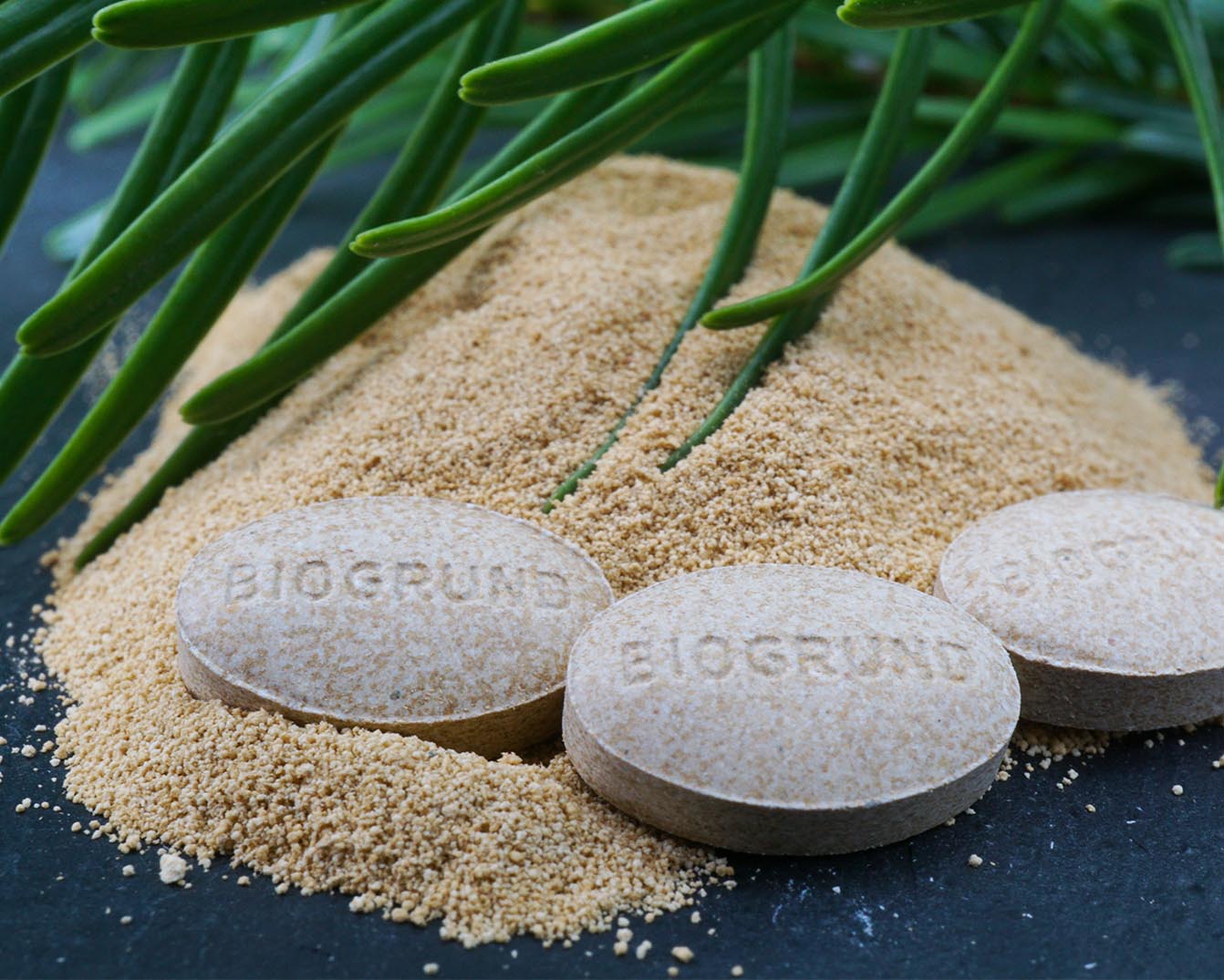

Hemp in tablets or capsules – Excipients for CBD

Hemp products are mostly sold in liquid form. Companies who are trying to change this and offer solid dose products have to face different challenges.

The challenges depend on their choice of solid dosage form (tablets or capsules), technical requirements, their marketing strategy (color, legal ingredient restrictions) and their consumer requirements (Clean Label, Organic, Free of).

BIOGRUND has been working with solid dose products for more than 20 years. The increasing know-how is on the one hand based on close cooperation with our suppliers and partners but even more on the close relationship and technical project work with our clients. Our products are constantly improved based on our client’s feedback.

Looking for the right ingredients for formulating your solid hemp product

According to the current consumer healthy lifestyle trend, the following powdered premix formulations provide the right characteristics for your state-of-the-art CBD tablet or capsule. The formulations are free of silica, titanium dioxide, palm oil and magnesium stearate. All ingredients are natural or organic and thus support your Clean Label strategy.

How you can achieve your target of a solid hemp product in an easy way:

Step 1 – Oil to Powder

Several CBD and THC products are oily substances. CompactCel® MAB for oil absorption is developed to absorb high quantities of oil but to keep flowability and powder form.

Step 2 – Tablet or Capsule?

Step 2 – Tablet or Capsule?

The manufactured oil powder cannot yet be used for further manufacturing. Other raw materials have to be added to be able to fill it into capsules or press it into tablets.

Humidity protection

During the process the product could be exposed to humidity. CompactCel® MAB for water absorption avoids that the powder blend loses the required flowability.

Increasing flowability

Depending on the used equipment a higher production speed can be targeted. To meet the objective the powder blend has to have a certain flowability. CompactCel® FLO helps to improve the flowing properties of the whole blend.

Binder

A dry binder is required to achieve a stable tablet. We offer different grades of CompactCel® for direct compression for this purpose.

Lubrication

To ensure a smooth running process CompactCel® LUB is recommended as a lubricant.

All-in-one

Our tailor made BonuTab® is a fully formulated tablet or capsule ingredient blend. It is adjusted to your requirements and simplifies the whole supply chain and production process.

Step 3 – Finishing

Step 3 – Finishing

A film coating can be used to protect the product but as well to increase its value and aesthetic appearance.

Tablet Coating

There are different reasons why the tablets could be coated. Depending on your requirements we can help with our AquaPolish® or NutraPolish® Organic products. The coating protects your product against oxidation and environmental influences like moisture or UV-radiation.

Consumer expectations of the product, which should always be considered:

- Is the color of the product appealing?

- Is a good swallowability given?

- Does the product has a good taste and odor masking?

Capsule Coating

Coated capsules cannot be opened without noticing, no exchange of the powder possible.

Formulation-Partner

BIOGRUND goes beyond the range of ingredients by delivering technical support for development and production of tablets & capsules. This also includes tailor-made developments for CBD and clean label formulation needs.

Interested in a product from BIOGRUND?