An Integrated Real-time Monitoring and Statistical Process Control Approach for Coating Process and Product Quality via In-line Optical Coherence Tomography

Abstract

Purpose

The thickness and other quality aspects of pharmaceutical coatings can be significantly impacted by coating process conditions. Under certain circumstances, they can notably influence the drug product performance such as dissolution profiles. Typically, a target coating thickness range is defined in the coating process. The coating thickness is conventionally measured off-line via weight or diameter gain. However, these established methods do not allow real-time monitoring of the product quality during the coating process. Further, options to react to any deviations are limited due to the lack of real-time information on the actual process and product state. The focus of this study was the development of a data-driven approach for real-time process control.

Methods

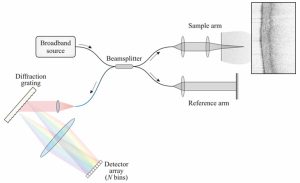

Optical coherence tomography (OCT) is a novel technique for in-line monitoring of pharmaceutical coating processes, which acquires coherent and accurate data on coating thickness and other quality attributes in real-time. Using the quality by design (QbD) principles, this study developed and implemented an integrated approach for tracking the process and the coating layer quality in real-time. Data on coating thickness and roughness were compared with data obtained from optimal process conditions.

Results

The integrated real-time process monitoring and control approach was executed and tested in a laboratory scale pan coating process. Coating runs with standard conditions and with intentional process upsets were performed. Using the real-time process trajectory to actively control the coating process, the dissolution profiles of the coated tablets produced in the event runs matched the optimal profiles well.

Conclusion

Tracking the coating process trajectory via OCT is a novel method for controlling the coating process and the related product quality attributes in real-time. It can help to realise full benefits of real-time control in addition to end-point determination and can support product development activities as well as the operation during commercial manufacturing.

Read more here

Sacher, S., Fink, E., Herndler, V. et al. An Integrated Real-time Monitoring and Statistical Process Control Approach for Coating Process and Product Quality via In-line Optical Coherence Tomography. J Pharm Innov (2023). https://doi.org/10.1007/s12247-023-09750-5

Read more on Phyllon OSeeT – Measuring coating thickness and characteristics of tablets here: