Phyllon OSeeT – Measuring coating thickness and characteristics of tablets

Measure the coating thickness and characteristics of tablets or pellets

Phyllon was founded in Graz, in March 2016, to produce and distribute the innovative OSeeT technology,

based on Optical Coherence Tomography (OCT) research developed by The Research Center Pharmaceutical Engineering GmbH (RCPE). The focus of the OSeeT are enteric coatings (EC) and modified-release (MR) coatings.

The characteristics of the coating layer are revealed via OSeeT:

Mean coating thickness

→ progress of coating processIntra-particle and inter-particle coating variability

→ for quality and homogeneity of the applied coatingRoughness

→ optical quality of the surface

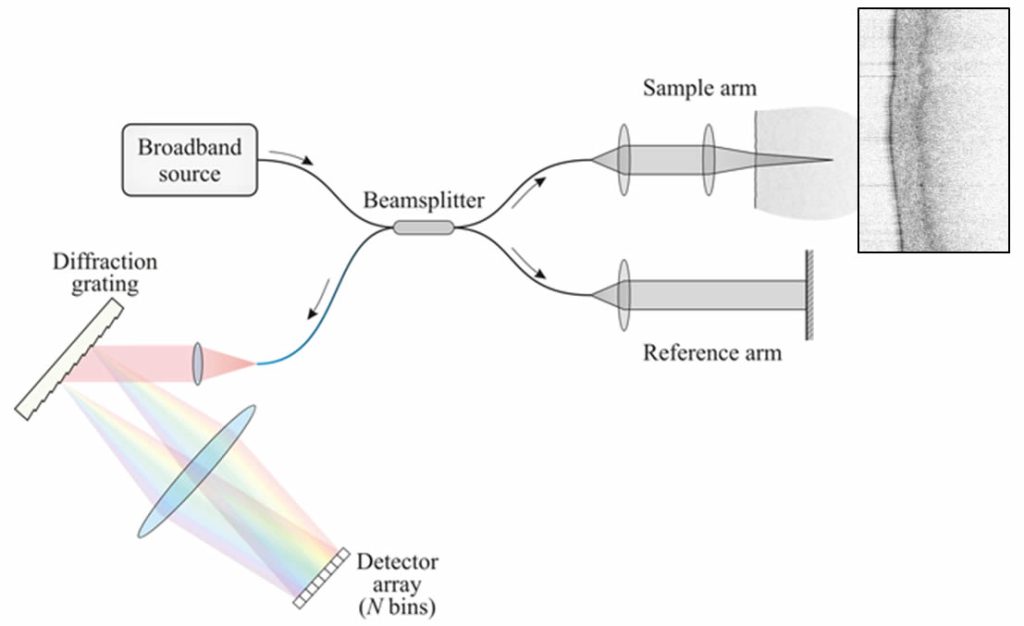

OCT PRINCIPLE

The Technology behind OSeeT is Interferometry

- OCT is based on white light interferometry:

– broad bandwidth resulting in low-coherence length

– defines the axial (=depth) resolution - Light is split into a reference and a probe path

- Optics of sample arm focus light and define lateral (=surface) resolution

- Interference of light reflected back from both paths

- Spectrometer (grating, CCD line scan camera)

- Depth-information is generated from interference fringes by Fourier-transformation (FFT)

- Measurement of a single depth scan

ADVANTAGES

It is a fast and non-destructive system to evaluate the quality of film-coatings.

- The system is capable of scanning 60 images/sec. No other in-line and real-time technique can achieve the same. Once connected, the OSeeT provides immediate measurements of the thickness of the film coating, in microns. No specialised operator training is required.

An incredible level of detail.

- Through analysing the pictures produced, it is possible to see the internal structure of the coating (i.e.: air bubbles and entrapped inclusions).

- Undesirable coating thickness variations can be revealed.

- The information that the OSeeT produces, for functional coatings above 10-15 microns, is an outstanding support for quality control of the product, both in development and also in production.

OSeeT provides direct measurement of the coating thickness.

- The measurement is based on a physical principle (light reflection and interference). It is not necessary to seek a secondary reference.

- It is also possible to review the roughness of the coating surface.

- OSeeT saves time during development and maintenance, greatly reducing TCO (“Total Cost of Ownership”).

- In order to calculate accurate measurements, only the refractive index of the coating solution needs to be known.

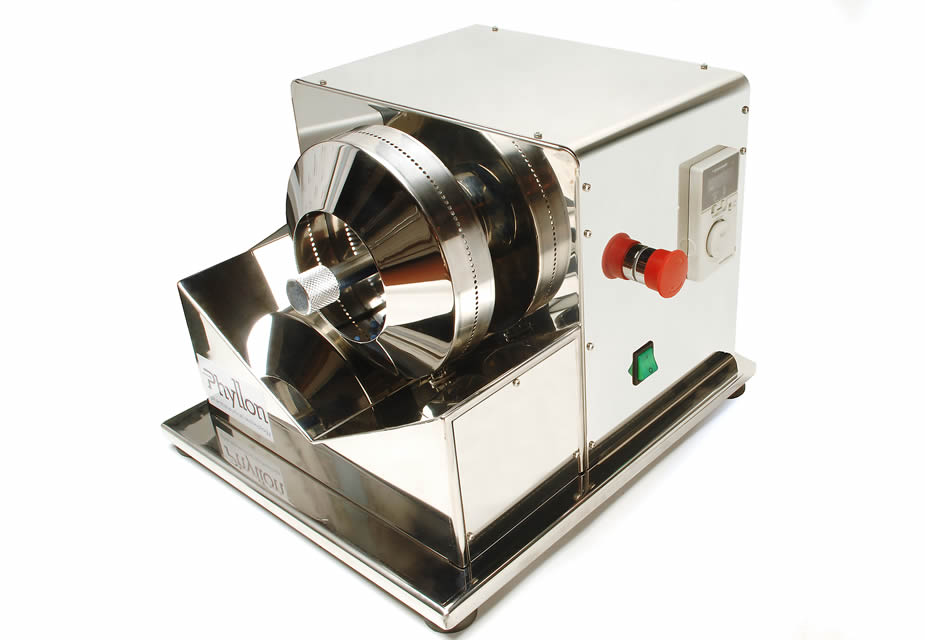

Through using OSeeT it is possible to closely monitor the performance of pan coaters.

-

The measurements and the images can immediately reveal malfunctioning or poor set-up of the coater and also if the coating solution or suspension has been prepared properly.

The 1D OSeeT probe is small.

- This facilitates positioning inside the pan in existing coaters.

The probe is not in direct contact with the product when used with perforated pans.

Video on at line measurement

Gallery:

Brochures:

Contact

Phyllon GmbH

Inffeldgasse 13/4. OG

8010 Graz

Germany

Gianpiero Raffa

M +39 335.6039648

T +39 02.89785701

F +39 02.89785799

[email protected]