Material-Sparing Feasibility Screening for Hot Melt Extrusion

Abstract

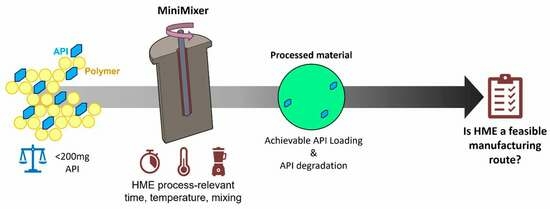

Hot melt extrusion (HME) offers a high-throughput process to manufacture amorphous solid dispersions. A variety of experimental and model-based approaches exist to predict API solubility in polymer melts, but these methods are typically aimed at determining the thermodynamic solubility and do not take into account kinetics of dissolution or the associated degradation of the API during thermal processing, both of which are critical considerations in generating a successful amorphous solid dispersion by HME. This work aims to develop a material-sparing approach for screening manufacturability of a given pharmaceutical API by HME using physically relevant time, temperature, and shear.

Piroxicam, ritonavir, and phenytoin were used as model APIs with PVP VA64 as the dispersion polymer. We present a screening flowchart, aided by a simple custom device, that allows rapid formulation screening to predict both achievable API loadings and expected degradation from an HME process. This method has good correlation to processing with a micro compounder, a common HME screening industry standard, but only requires 200 mg of API or less.

Download the full article as PDF here Material-Sparing Feasibility Screening for Hot Melt Extrusion

or read it here

Materials

PXCM and PHY were purchased from TCI Chemicals (Tokyo, Japan) and Spectrum Chemical (New Brunswick, NJ, USA), respectively. RTV was provided by Abbott Laboratories (now AbbVie Inc., North Chicago, IL, USA). PVP-VA64 (Tg = 108 °C) was purchased from BASF (Ludwigshafen, Germany). All model compounds are poorly soluble drugs as per the biopharmaceutics classification system (BCS) [50], as detailed in Table 2. HPLC-grade methanol (MeOH) and acetonitrile (ACN) were purchased from Honeywell (Charlotte, NC, USA). Tri-fluoro acetic acid (TFA) and KH2PO4 were purchased from Fisher (Hampton, NH, USA). All materials were used as received. All water (H2O) used was MilliQ grade with 18.2 MΩ resistance.

Pluntze, A.; Beecher, S.; Anderson, M.; Wright, D.; Mudie, D. Material-Sparing Feasibility Screening for Hot Melt Extrusion. Pharmaceutics 2024, 16, 76. https://doi.org/10.3390/pharmaceutics16010076

Read more on “Binders” here: