Material tracking in a continuous direct capsule-filling process via residence time distribution measurements

Continuous production of pharmaceuticals requires traceability from the raw material to the final dosage form. With that regard, understanding the residence time distribution (RTD) of the whole process and its unit operations is crucial. This work describes a structured approach to characterizing and modelling of RTDs in a continuous blender and a tamping pin capsule filling machine, including insights into data processing.

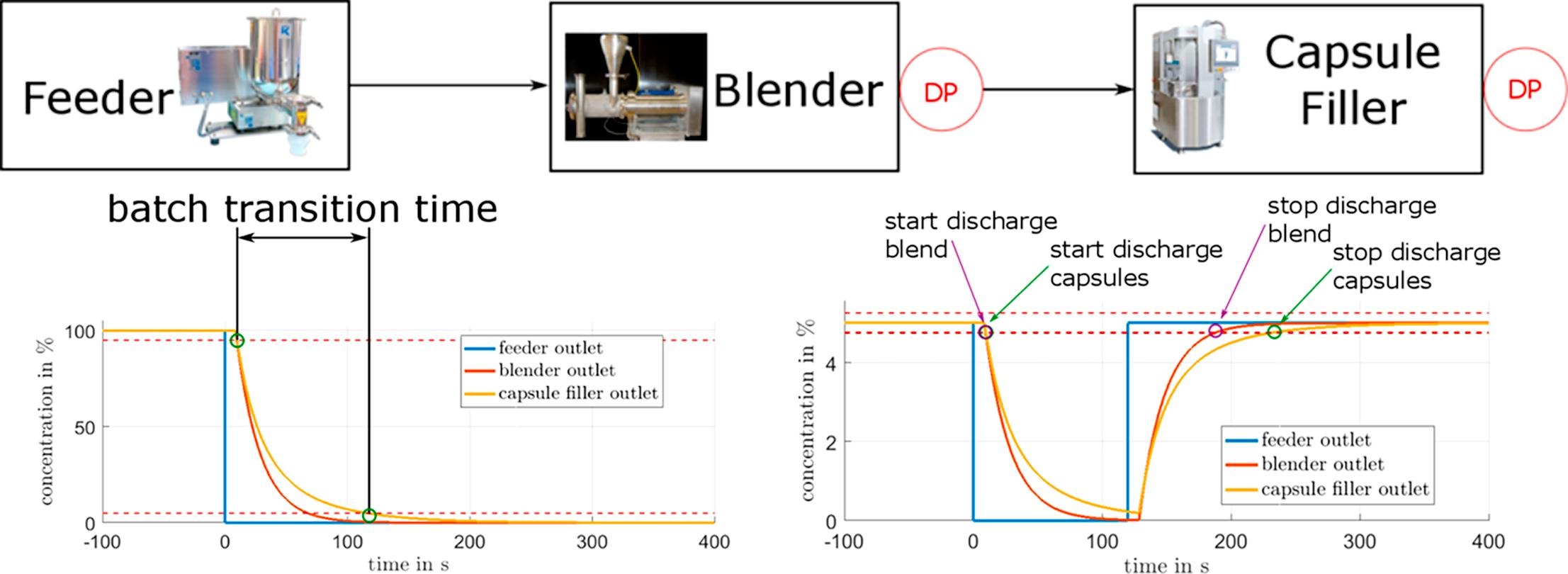

The parametrized RTD models were interconnected to model a continuous direct capsule-filling process, showing the batch transition as well as the propagation of a 2 min feed disturbance throughout the process. Various control strategies were investigated in-silico, aiding in the selection of optimal material diversion point to minimize the material waste. Additionally, the RTD models can facilitate process design and optimization. In this work, adaptions to the capsule filling machine were made and their influence on the RTD was examined to achieve an optimal machine setup. Continue on Material tracking in a continuous direct capsule-filling process via residence time distribution measurements

Materials: All experiments were conducted with sugar pellets (Pharm-a- Spheres®, Hanns G. Werner GmbH + Co.KG, Tornesch, Germany).

Article information: Julia Kruisz, Jakob Rehrl, Eva Faulhammer, Andreas Witschnigg, Johannes G. Khinast,

Material tracking in a continuous direct capsule-filling process via residence time distribution measurements,

International Journal of Pharmaceutics, Volume 550, Issues 1–2, 2018. https://doi.org/10.1016/j.ijpharm.2018.08.056.