High Drug Loaded Pellets produced by ProCell® Technology

Poster presented at 4th European Conference on Pharmaceutics 20-21 March 2023 | Marseille, France:

Drug loaded pellets were produced by using the ProCell® lab system technology. The aim was to produce highly drug loaded matrix pellets with an API-polymer ratio of approximately 95:5 by using different polymers, with the target pellet size between 315 µm and 500 µm.

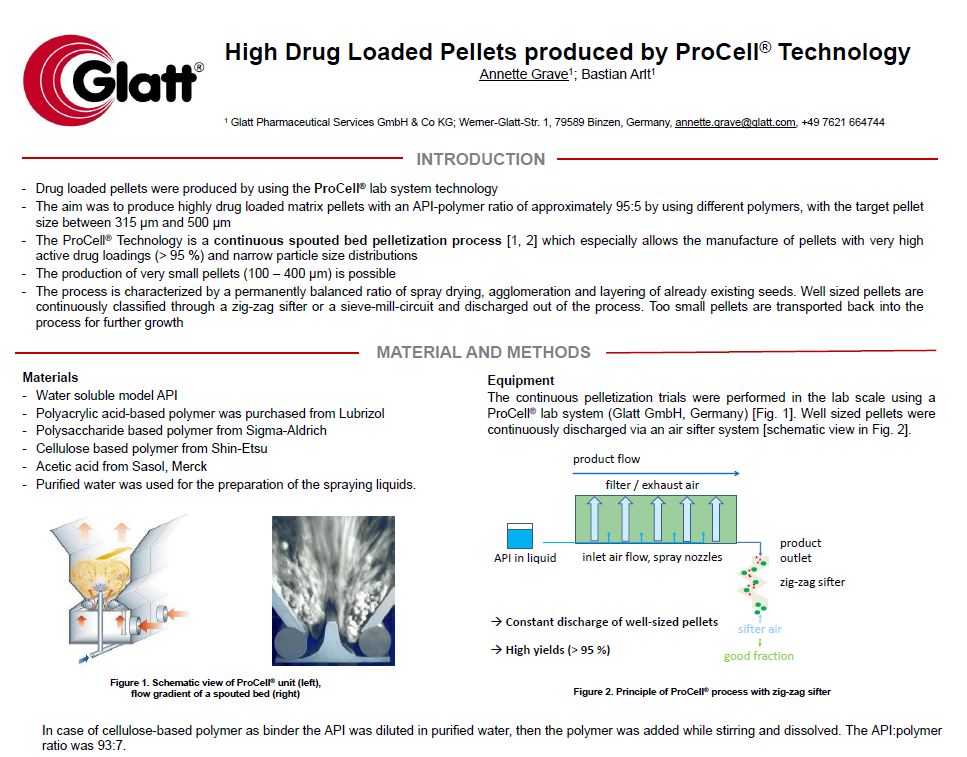

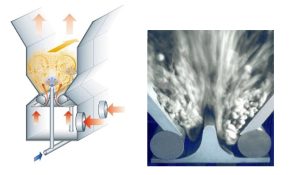

The ProCell® Technology is a continuous spouted bed pelletization process [1, 2] which especially allows the manufacture of pellets with very high active drug loadings (> 95 %) and narrow particle size distributions. The production of very small pellets (100 – 400 µm) is possible. The process is characterized by a permanently balanced ratio of spray drying, agglomeration and layering of already existing seeds. Well sized pellets are continuously classified through a zig-zag-sifter or a sieve-mill-circuit and discharged out of the process. Too small pellets are transported back into the process for further growth.

Materials and Methods

Materials

Despite the water soluble model API polyacrylic acid based polymer was purchased from Lubrizol, polysaccharid based polymer from Sigma-Aldrich, cellulose based polymer from Shin Etsu, acetic acid from Sasol, Merck. Purified water was used for the preparation of the spraying liquids.

Equipment

The continuous pelletization trials were performed in the lab scale using a Procell® lab system (Glatt GmbH, Germany) [Fig. 1 and 2].

The polyacrylic acid based polymer was dispersed in purified water and let swell by gently stirring for at least one hour; the API was added and dissolved while stirring, resulting in an API-polymer ratio of 95:5.

For the polysaccharid based polymer containing spraying liquids the polymer was dispersed in purified water, acetic acid was added to colloidally dissolve the polymer; API was dissolved in purified water, both liquids were merged and stirring continued. The spraying liquid contained an API:polymer ratio of 99:1.

In case of , cellulose based polymer as binder this the API was diluted in purified water, then the polymer was added and while stirring and dissolved. API:polymer ratio was 93:7.

Characterization of Pellets

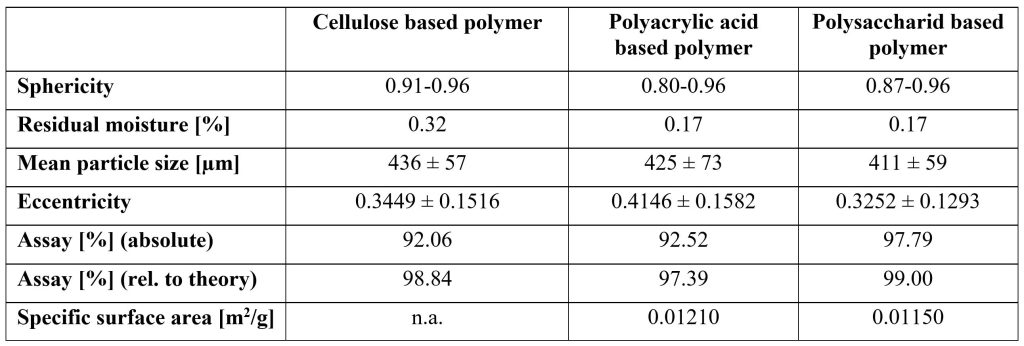

The obtained pellets were characterized and compared concerning particle size, sphericity, eccentricity (sieve analysis, Camsizer® XT, Eyecon2TM), porosity (gas pycnometry, AccuPyc 1330, Micromeritics), residual moisture (loss on drying, Mettler Toledo Halogen Moisture Analyzer HB 43), specific surface area (gas pycnometer AccuPyc 1330, Matersizer 2000).

Assay was tested with an internal test procedure, which was modified for analysis of pellets.

Results and Discussion

Pellets with the target particle size between 315 and 500 µm were produced. Round pellets with a narrow size distribution were obtained [Figures 3 – 5, table 1]. Assay values of up to 98 % were analyzed.

Conclusion

The ProCell®-Technology is an adequate technology for the development and manufacture of highly drug loaded pellets. The manufacture of pellets with different ploymers and AOI:polymers ratios is possible. Narrow particle size distributions and smooth pellets surfaces can be obtained.

Download the full poster as PDF here:

Authors: Annette Grave, Bastian Arlt, Glatt Pharmaceutical Services, Werner Glatt Str. 1, D-79589 Binzen,