Comparing various plasticisers regarding their effect on the film-coating properties of Kollicoat® MAE 30 DP

Various active pharmaceutical ingredients (APIs) are either aggressive to the stomach’s mucosa or vulnerable to the acidic nature of the gastric juice. Solid oral dosage forms carrying one of these APIs thence require gastric resistant functionality. Poly(methacrylic acid-co-ethyl acrylate) [MAE] based coats are most frequently applied to introduce gastric resistant functionality to a solid oral dosage form.

The polymer is available in three different compendial grades (Ph.Eur.):

- an aqueous dispersion: Methacrylic acid – ethyl acrylate copolymer (1:1) dispersion 30 per cent (e.g. Kollicoat® MAE 30 DP),

- a powder grade (non-partly pre-neutralised): Methacrylic acid – ethyl acrylate copolymer (1:1), Type A (e.g. Kollicoat® MAE 100-55)

- a powder grade (partly pre-neutralised [6 mol%]): Methacrylic acid – ethyl acrylate copolymer (1:1), Type B (Kollicoat® MAE 100 P)

In the field of gastric resistant film-coating, the choice of plasticiser is particularly crucial with respect to processability and properties of the formed film. Furthermore, regulatory aspects regarding maximum daily intake or the use of select plasticisers in specific regions have to be regarded as well.

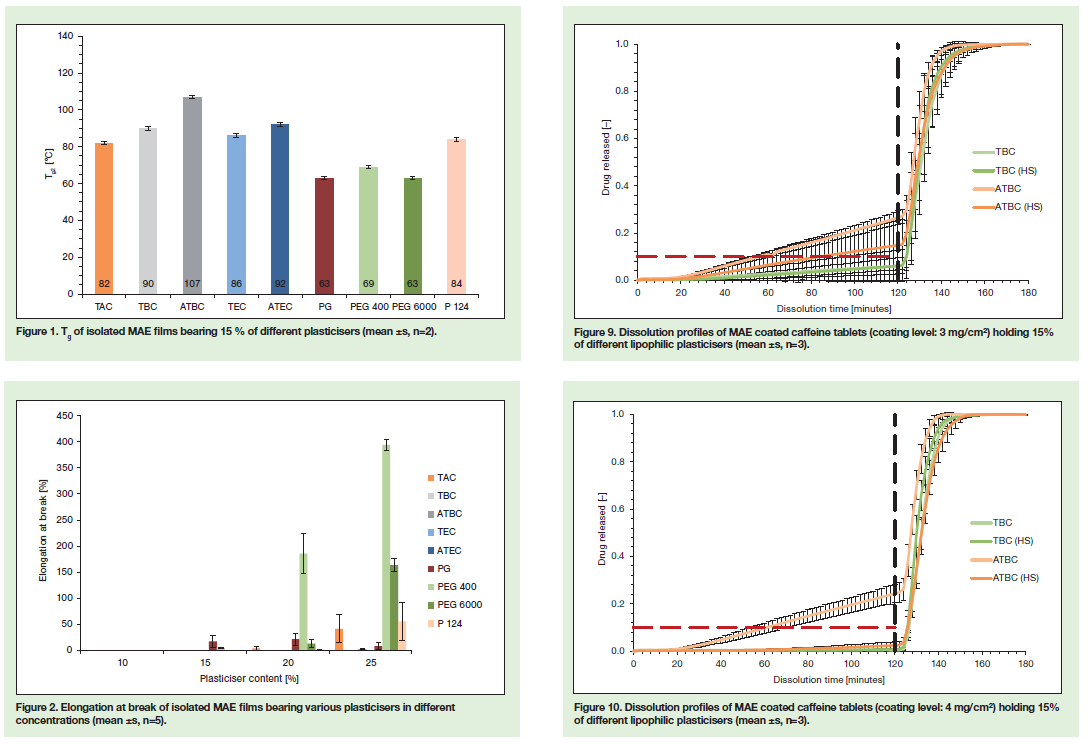

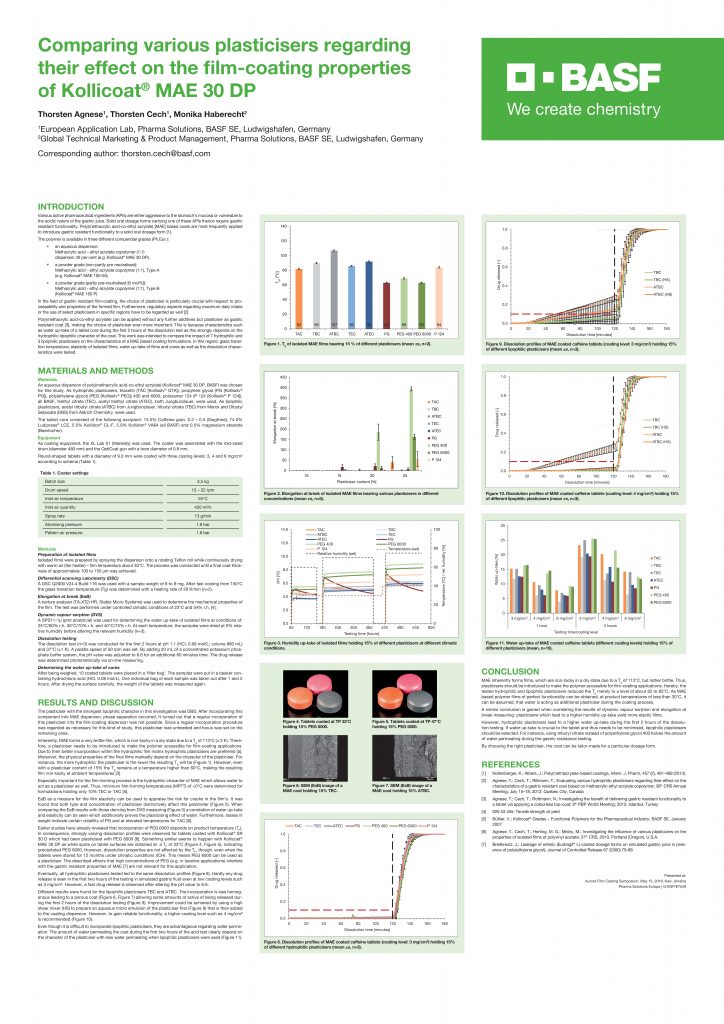

Poly(methacrylic acid-co-ethyl acrylate) can be applied without any further additives but plasticiser as gastric resistant coat, making the choice of plasticiser even more important. This is because characteristics such as water up-take of a tablet core during the first 2 hours of the dissolution test as this strongly depends on the hydrophilic-lipophilic character of the coat. This work was intended to compare the impact of 7 hydrophilic and 3 lipophilic plasticisers on the characteristics of a MAE based coating formulations. In this regard, glass transition temperature, elasticity of isolated films, water up-take of films and cores as well as the dissolution characteristics were tested.

Click image to enlarge: MORE ON BASF

MORE ON BASF