Dry Granulation in Solid Oral Formulation: Advantages of Spray-Dried Mannitol in Roll Compaction

The Application of Fillers and Binders in Solid Dosage Formulation

Pharmaceutical excipients are frequently used as fillers and fillers/binders in the formulation of solid dosage forms. Fillers add volume and confer mechanical properties that offer greater flowability and compressibility which facilitate manufacturing and increase final formulation robustness and content uniformity. These aspects are particularly relevant in the formulation of highly potent, low dose active pharmaceutical ingredients (APIs) where content uniformity can be challenging.

Advantages of Mannitol for Solid Dosage Formulation

In recent years, mannitol has gained popularity as an excipient in solid dosage formulation due to its beneficial physicochemical properties. Because it is chemically inert, has good compactibility, and low hygroscopicity1, it can be used in formulations to produce robust tablets and as a diluent in rapidly dispersing oral dosage forms.2 It also has a good taste and mouth feel enabling its use for chewable, sublingual and orodispersible tablet formulations.

A variety of pre-processed and unprocessed grades of mannitol are commercially available for use as an excipient in pharmaceutical formulations. For production of dosage forms for oral administration by direct compression processes, directly compressible grades are available.

In cases where a direct compression process is not suitable due to possible separation or de-mixing of components of varying particle sizes, dry granulation can be included before tableting. This step can increase the bulk density of powders and improve flow properties. Moreover, it helps to improve content uniformity of the final formulation which is essential when processing highly potent APIs. Mannitol can serve as a filler/binder for dry granulation by roller compaction, which can be used for moisture or heat sensitive APIs as no solvents, liquid binders or elevated temperatures are applied in the process.3

The following studies, funded by our organization and performed by researchers from Heinrich-Heine University, Duesseldorf, Germany, explored tableting behavior and comparative compressibility of various pre-processed and unprocessed mannitol grades in dry granulation. The roller compaction behavior of different mannitol grades was investigated in placebo formulations or in combination with enalapril maleate as a model low-dose API. Results of these studies reveal differences in performance and can help guide selection of the best mannitol grade for dry granulation processes.

Tableting Behavior of Spray-Dried Mannitols

This study compared the suitability of spray-dried mannitol grades for roller compaction and the suitability of the resulting granules for tableting processes.4

Five spray-dried and commercially available mannitol grades (designated “A” through “E”) with similar particle size distributions were selected to explore their suitability for roller compaction and subsequent tableting processes.

Powders were granulated using an instrumented roller compactor (Mini-Pactor® 250/50, Gerteis Maschinen + Processengineering AG) with the compaction force set to 2 kN/cm and 10 kN/cm, respectively; the gap between the rolls (1.5 mm) and the roll speed (5 rpm) were kept constant during the process. For unprocessed grades, the roll speed was set to 3 rpm with a gap of 2.0 mm. Ribbons were granulated with a star-granulator using a 1.25 mm sieve. The granules were mixed with 1% magnesium stearate and compressed on a rotary tablet press (Pressima, IMA S.p.A.) equipped with planar 10 mm punches at compression forces of 3, 6, 9, 12 and 15 kN into tablets with a total tablet weight of 500 mg.

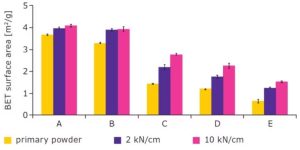

Tablets formulated using mannitol by Merck A and B (Parteck® M 100 and Parteck® M 200 excipients, respectively) achieved the highest tensile strength after direct compression due to the large specific surface area of the raw material (Figure 1). In contrast, mannitol E lacked a sufficient surface area for bonding during tableting and this led to tablets with decreased mechanical resistance (Figure 1, Figure 3). BET results show that in general, when compared to the raw material, the specific surface area of the granules was increased after roller compaction. This effect became more apparent at high compaction forces and could be detected for every investigated mannitol grade. The increase of granule surface area can be attributed to extensive fragmentation of the brittle mannitol which is more pronounced when higher compaction forces are applied.5

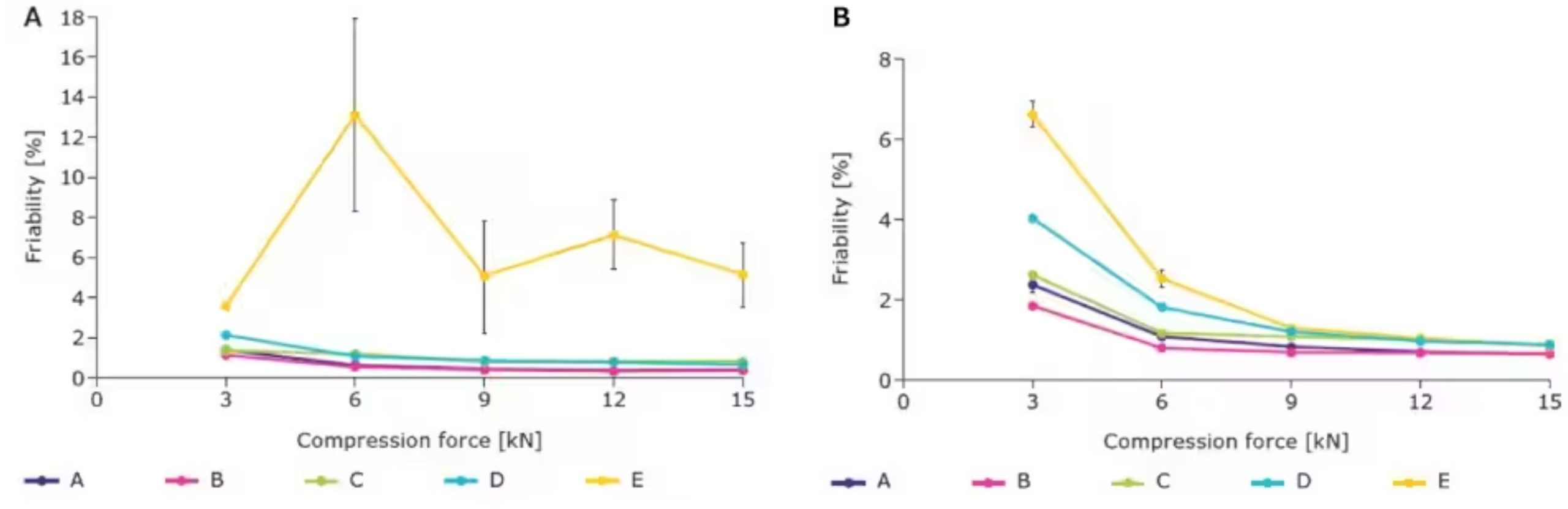

With increasing compaction forces used in the roller compaction process, a loss of compressibility was observed for all excipients (Figure 2). This effect can be associated with particle size enlargement and the work-hardening phenomenon following roller compaction.6 As shown in Figure 3, however, both mannitol A and B required less compression force to achieve the desired friability of <1%.

This study demonstrated that while roller compacting spray-dried mannitol grades resulted in robust tablets, final formulation performance was strongly dependent on the type of mannitol. Parteck® M 100 and Parteck® M 200 mannitols (A and B) were shown to produce granules with the largest surface area and tablets with highest tensile strength and lowest friabilities.

Comparison of Pre-Processed and Unprocessed Mannitols

The purpose of this study was to compare the roller compaction and tableting behavior of commercially available pre-processed (spray-dried and granulated) mannitol grades and unprocessed crystalline mannitol in its β- and δ-modification.7

The mannitol grades evaluated included two preprocessed granulated grades, designated “A” and “B”, and two spray-dried grades, designated “C” (Parteck® M 200 excipient) and “D”. Crystalline mannitol in the β- (“E”) and δ-form (“F”) were selected as unprocessed material. All powders were granulated, and tablets produced and characterized as described in the first case study. Compression forces of 3–18 kN were applied to produce the tablets.

While roller compaction of mannitol A and B led to tablets with sufficient tensile strength applying compression forces ≥ 9 kN, granules made of spray-dried raw materials (C and D) were characterized by a superior compressibility and higher tensile strengths even at lower compression forces (Figure 4).

As in the first case study, a loss in compressibility was observed for every mannitol grade (pre-processed and unprocessed β- and δ-mannitol) with increasing compaction force used in the roller compaction process (Figure 4). This can be attributed to particle size enlargement and the work-hardening phenomenon.6

In accordance with the results of the first case study, the specific surface areas of the granules increased after roller compaction (Figure 5). This effect became more apparent at high compaction forces and can be attributed to the strong fragmentation behavior of mannitol.8 Tablets of Parteck® M 200 excipient (“C”) showed a considerably larger interparticular contact area due to the large BET surface area of both powder and granules (Figure 5) which resulted in higher tensile strength (Figure 4).

This study demonstrated that while roller compaction of granulated starting materials and crystalline δ-mannitol resulted in granules and tablets with desirable properties, the spray-dried grade with the largest surface area (mannitol C = Parteck® M 200 excipient) showed good compactibility during the dry granulation process and exhibited superior compressibility during the tableting process when compressed into the final dosage form.

Read the full original article here

Source: Merck, website Dry Granulation in Solid Oral Formulation: Advantages of Spray-Dried Mannitol in Roll Compaction (sigmaaldrich.com)

Read our introductory article on Mannitol here: