Prevention of tablet weight loss and tablet surface abrasion on tablet coating using highly compactible microcrystalline cellulose (MCC) CEOLUS™ KG-1000

OBJECTIVE

When large-size tablets are coated, there are often problems of tablet surface abrasion and tablet weight loss due to coating. For these formulations, CEOLUSTM KG-1000, an extremely highly compactible MCC is an effective tool to increase tablet hardness and improve friability, preventing these problems.

CEOLUSTM KG-1000 has a particle structure that is fibrous which improves hardness during compaction. In this study, we investigated the addition of CEOLUSTM KG-1000, and other MCC grades; KG-802 and PH-102 to placebo tablets to demonstrate the effectiveness in preventing weight loss and surface abrasion during the coating of large-size tablets.

What is CeolusTM KG-1000?

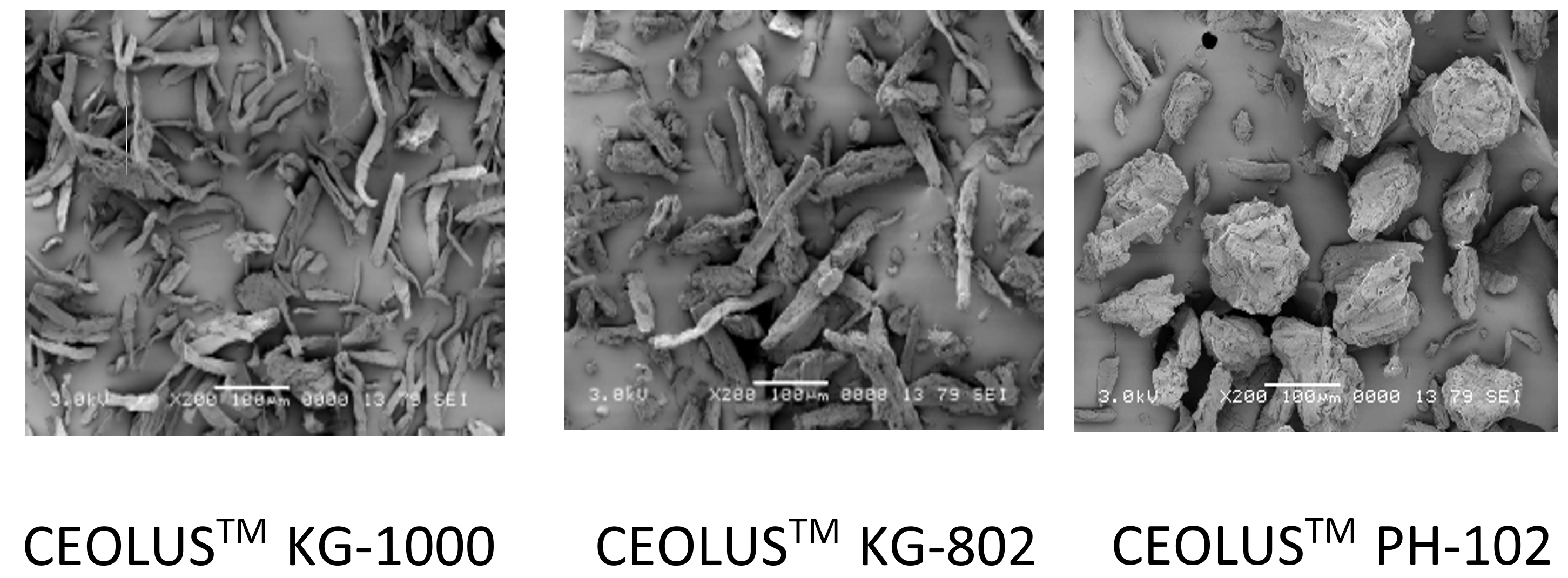

Particle morphology

Fig.1 Particle morphology of CEOLUSTM grades:

Powder properties

Tab.1 Powder properties of CEOLUSTM grades:

| Bulk density (g/cm3) | Av.particle diameter (µm) | Repose Angle (o) | |

| KG-1000 | 0.12 | 50 | 57 |

| KG-802 | 0.21 | 50 | 49 |

| UF-711 | 0.22 | 50 | 42 |

| UF-702 | 0.29 | 90 | 34 |

| PH-101 | 0.29 | 50 | 45 |

| PH-102 | 0.30 | 90 | 42 |

EXPERIMENTAL PROCEDURE

TABLET PROPERTIES

Fig. 2 Tablet hardness:

Fig. 4 Roughness of tablet surface:

Fig. 4 Roughness of tablet surface:

Fig.5 Roughness of tablet surface at the compression force of 10 kN after coating test:

Fig.5 Roughness of tablet surface at the compression force of 10 kN after coating test:

The tablet hardness of the KG-1000, KG-802 and PH-102 formulations was 142 N, 120 N, and 95 N at the compression force of 10 kN, and 213 N, 193 N, and 158 N at the compression force of 15 kN respectively (Fig.2).

The tablet weight loss of KG-1000, KG-802 and PH-102 formulation was -1.11%, -1.17%, and -1.47% at the compression force of 15 kN respectively.

The KG-1000 formulation provides a harder tablet with less weight loss (Fig.3). Tablet surface pixels were measured as a parameter of the abrasion level. The pixels of the KG-1000, KG-802 and PH-102 formulations were 21,120 pixels (px); 47,334 px, and 54,115 px at the compression force of 10 kN, and 16,676 px, 17,796 px, and 33,987 px at the compression force of 15 kN respectively. This demonstrates less abrasion on the surface of the KG-1000 formulation. (Fig. 4,5)

CONCLUSION

CEOLUSTM KG-1000 has the highest compactibility in all MCC grades due to the entanglement of its long fibrous particles during compression. Consequently, CEOLUSTM KG-1000 is effective in preventing weight loss and abrasion of large-size tablets during coating.

REFERENCE

The data of this page is a property of Asahi Kasei Corporation.