Transform Liquid-form Active Ingredient into Powder form with High Performance Liquid Carrier

Introduction

Several major active ingredients for human health, such as vitamin A/D/E/K, DHA/EPA, and natural herbal

extracts are supplied in liquid form. Emulsified powder and microencapsulation were previously known as the

major ways to provide better compatibility with other ingredients, but they don’t meet the workability in the

compression process. The powderization method of liquid ingredients with liquid carrier is offered, but there is no

method to fulfill the adequate liquid carrying performance.

Tomita’s FLORITE is a macro porous calcium silicate which has considerable liquid absorbency and retains liquid

stably. We offer a practical powderization capability for liquid active ingredients that helps the development of a

new combination use with other active ingredients.

Liquid carrier

For the model material of active liquid ingredients, fish oil was selected due to high viscosity liquid and commonly

supplied in single component products.

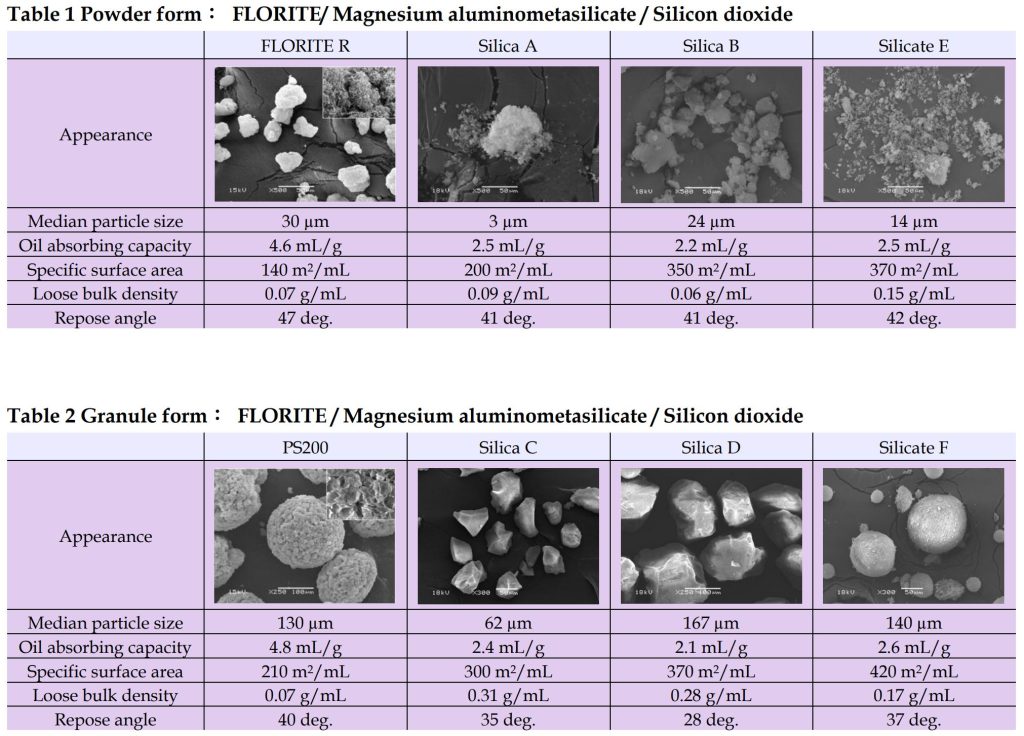

FLORITE R and PS-200 were applied to tuna fish oil absorbing in the loading ratio of 1 to 2, and silicon dioxide

(Silica) and a neutral type of magnesium aluminometasilicate (Silicate) were chosen as reference material because

they are well-known liquid carriers. Liquid was absorbed in a closed mixing machine.

FLORITE is synthetic calcium silicate which has a petaloid structure with developed deep and large macro pores

on the particle. Such pores are applicable to liquid carrying, binding, stabilizing and solid dispersion.

FLORITE R is standard product of the FLORITE brand, and it is a light powder with high liquid absorbency.

FLORITE PS-200 is a fine granular type, and it has spherical form offering higher flowability. Both FLORITE R and

PS 200 are much higher liquid absorbency than reference materials.

In the case of Silicon dioxide (Silica), both powder and granule form have well flowability, but granule forms are

more dense granules with better flowability. In the case of magnesium aluminometasilicate (Silicate), both powder

and granule forms showed higher liquid absorption compared to silicon dioxide.

Considering these results, this study shows their Liquid absorbency neither depends on particle size nor specific

surface area

Liquid powderizing study

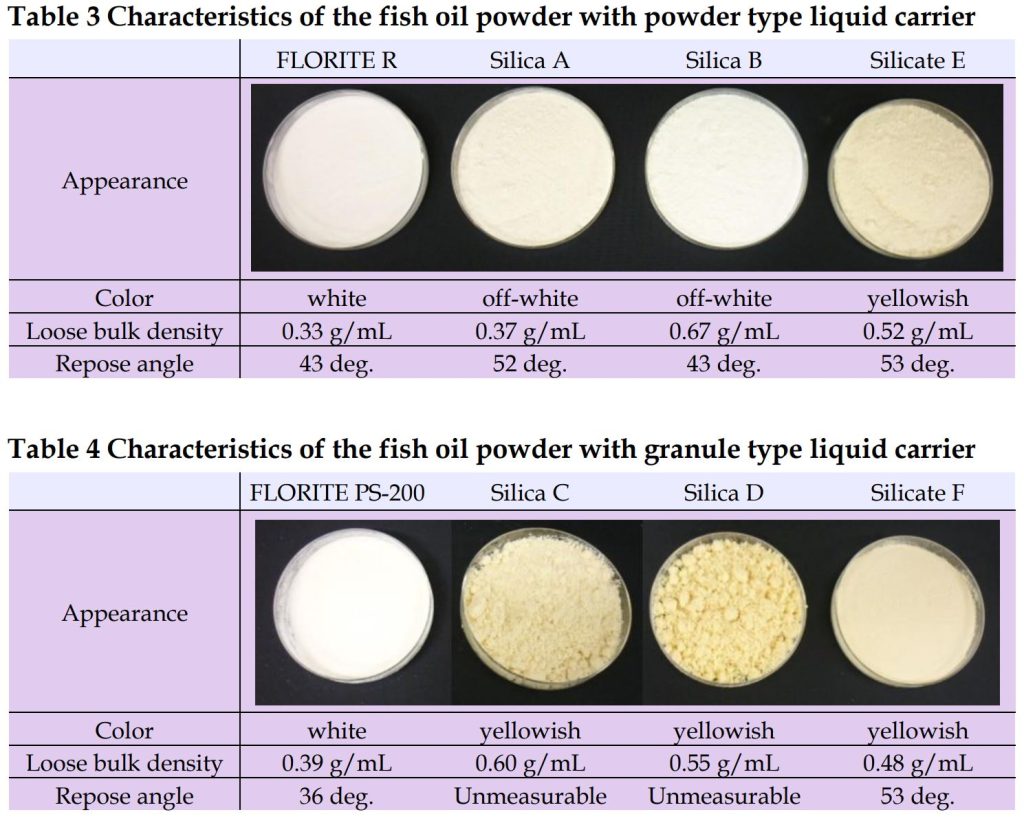

Fish oil carrying powder with each material in the loading ratio of 1 to 2, was prepared in a closed mixing machine.

Although the fish oil powders with other silica/silicate were showing a yellow color which came from the original

fish oil, FLORITE doesn’t change its color. Color change occurs significantly in granule type liquid carriers. It

suggested that FLORITE retains the oil inside deep particles. Regarding flowability, in the case of FLORITE,

flowability was stable even after carrying the fish oil, on the other hand, in the case of silica/silicate, flowability

was decreased. The deterioration of flowability is caused by bled fish oil on the particle surface. It means that

FLORITE can retain the oil surely inside the particles. Especially in the case of granule type silica, retaining fish oil

stably was difficult and fish oil was bled out and aggregated remarkably.

Difference in liquid carrying mechanism

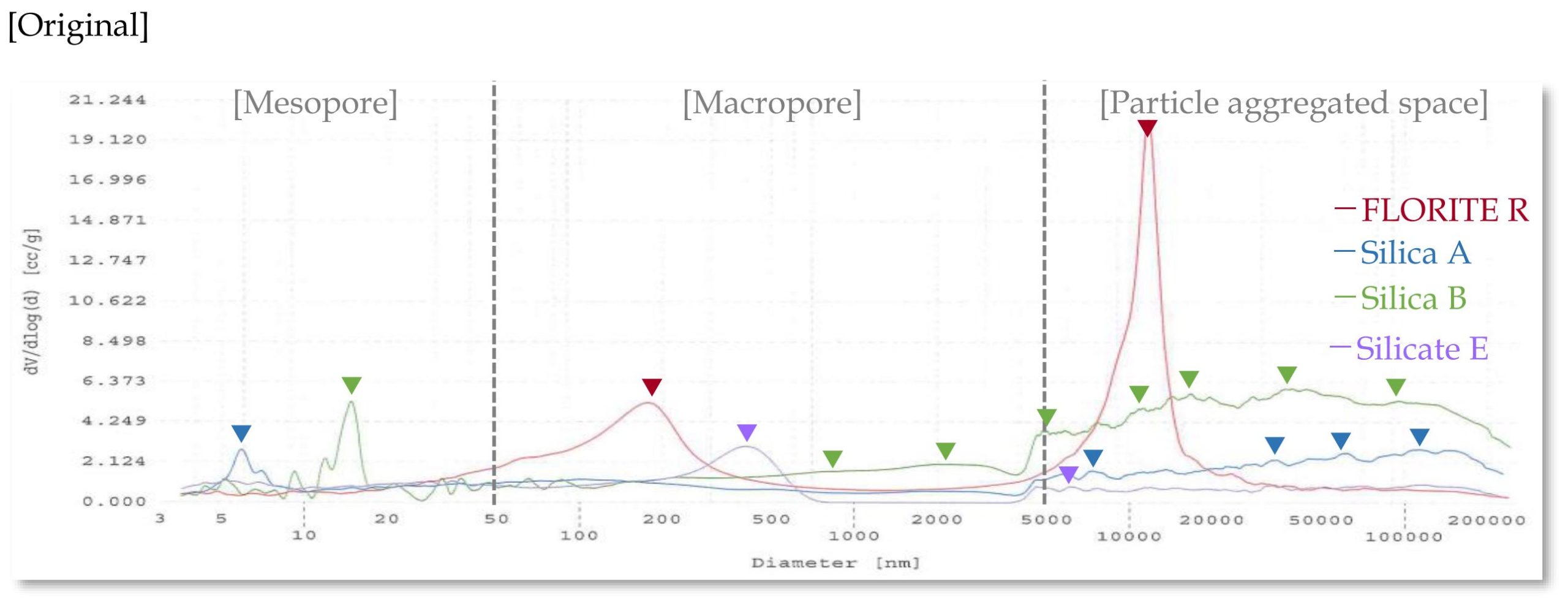

Specific surface area which we measured using nitrogen gas adsorption was uncorrelated with the liquid

absorbency as shown in Table 1 and 2. It seems that the macro structure of the particle increases liquid absorption.

We measured the larger pore size distribution on the surface using mercury porosimetry analysis. FLORITE and

silicate E have macropores from 50 to 5000 nm, other silicas have mesopores up to 50 nm. Silicate F has both. In all

liquid carriers, particle aggregated space(interspace) was detected.

The total space of mesopore and macropore shows liquid absorbing capacity, it is proven that FLORITE has the

highest capacity in all carriers.

In the case of FLORITE, fish oil was filled into macropores shown in the pore volume decreasing, however a lot of

empty pores remain. Silicate E also absorbed the oil into macropores, although almost all pores were filled up.

Silicate F captures the oil in both macropores and mesopores, however mesopores disappeared after absorption.

See the full White Paper on “Transform Liquid-form” here

(click the picture to download the white paper)

Source: Tomita, White Paper “Transform Liquid-form”

Do you need more information or a sample of Tomita excipients?