Influence of mechanical and thermal energy on nifedipine amorphous solid dispersions prepared by hot melt extrusion: Preparation and physical stability

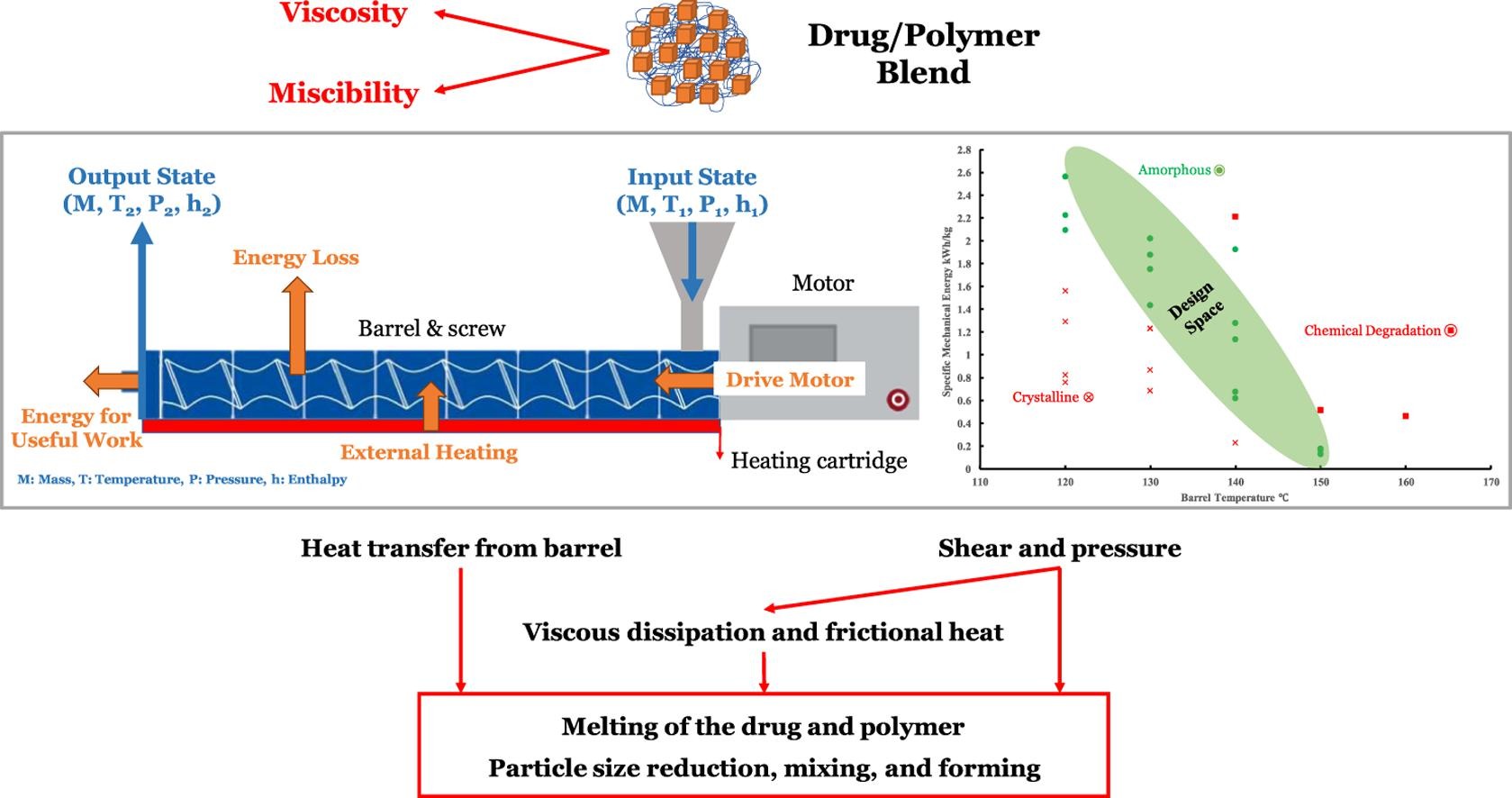

Hot melt extrusion (HME) has been used to prepare solid dispersions, especially molecularly dispersed amorphous solid dispersions (ASDs) for solubility enhancement purposes. The energy generated by the extruder in the form of mechanical and thermal output enables the dispersion and dissolution of crystalline drugs in polymeric carriers.

However, the impact of this thermal and mechanical energy on ASD systems remains unclear. We selected a model ASD system containing nifedipine (NIF) and polyvinylpyrrolidone vinyl acetate (PVP/VA 64) to investigate how different types of energy input affect the preparation and physical stability of ASDs. Formulations were prepared using a Leistritz Nano-16 extruder, and we varied the screw design, barrel temperature, screw speed, and feed rate to control the mechanical and thermal energy input. Specific mechanical energy (SME) was calculated to quantitate the mechanical energy input, and the thermal energy was estimated using barrel temperature.

We find that both mechanical and thermal energy inputs affect the conversion of crystalline NIF into an amorphous form, and they also affect the level of mixing and the degree of homogeneity in NIF ASDs. However, for small size extruders (e.g., Leistritz Nano-16), thermal energy is more efficient than mechanical energy in preparing NIF ASDs that have better stability.

More information about this topic

Article Information: Xiangyu Ma, Siyuan Huang, Michael B. Lowinger, Xu Liu, Xingyu Lu, Yongchao Su, Robert O. Williams III; Sciencedirect, 2019