Viscosity of API/fatty acid suspensions: Pitfalls during analysis

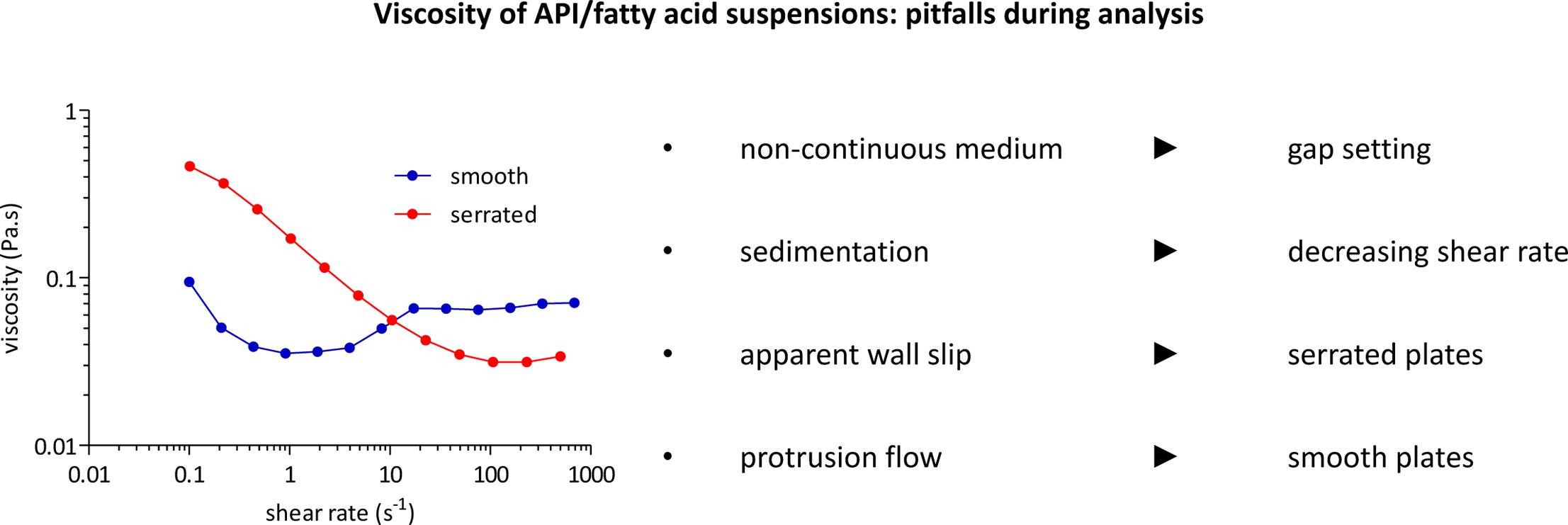

This article describes how to obtain reliable data during rheological analysis of active pharmaceutical ingredient/fatty acid suspensions. These materials are specifically used for prilling, an innovative pharmaceutical technique for the production of a multiparticulate dosage form. Nevertheless, presented guidelines are applicable for a wide range of pharmaceutical suspensions. Reliable rheological results can only be obtained when being aware of artefacts, such as a non-continuous medium, sedimentation, apparent wall slip and protrusion flow. To comply with the continuum hypothesis at high phase volumes (≥25% w/w), the required gap-to-particle-size ratio may be larger than the generally accepted 10:1 ratio.

Reproducible flow curves that are not disturbed by sedimentation during sample analysis can be obtained faster by varying the shear rate stepwise from high to low values. While apparent wall slip (at low shear rates) can be prevented via serrated instead of smooth plates, protrusion flow (at high shear rates) during measurements with serrated plates results in non-reliable data. Therefore, in general, high viscous suspensions with yield stress can be analysed with serrated plates, while low viscous suspensions without yield stress should be analysed with geometries having smooth surfaces. By following these guidelines, accurate rheological properties of pharmaceutical suspensions can be obtained. More on Viscosity of API/fatty acid suspensions

Conclusion

Reliable viscosity analysis of API/FA suspensions, and pharmaceutical suspensions in general, can only be obtained when taking the following guidelines into account:

- Prevent deviating phase volumes after sample loading, by loading an appropriate amount of sample to avoid trimming.

- At high phase volumes (≥25%), the required gap-to-particle-size ratio may be much larger than the generally accepted 10:1 to ensure that the continuum hypothesis is valid.

- Reproducible flow curves that are not disturbed by particle sedimentation during sample analysis can be faster measured by varying the shear rate stepwise from high to low values.

- To prevent apparent wall slip, serrated plates are recommended for highly viscous suspensions that presents shear thinning behavior and yield stress, while the flow curves of low viscous suspensions without significant shear thinning behavior and no yield stress are more accurately obtained with smooth plates to prevent measuring errors due to protrusion flow.

Viscosity of API/fatty acid suspensions: Pitfalls during analysis

E. De Coninck,F.H. Marchesini,V. Vanhoorne,T. De Beer,C. Vervaet

International Journal of Pharmaceutics, Volume 584, 30 June 2020, 119447