Rapid releasing naproxen Liqui-Pellet using effervescent agent and neusilin US2

Objective(s): Liqui-Mass technology has shown promising advantages in terms of commercial production and formulation manipulation. This study attempts to further explore the potential of enhanced drug release of effervescent Liqui-Pellet by optimizing certain parameters.

Materials and Methods: In the current study, pellets containing co-solvent, naproxen, coating and carrier materials were prepared via extrusion and spheronisation (Liqui-Pellet). Parameters investigated included polysorbate 80 concentration (as a co-solvent), water content and the presence or absence of Neusilin US2 as part of the new binary carrier mixture approach.

Results: It was found that the success of the Liqui-Pellet production was determined by the amount of polysorbate 80 and water used, where above a certain limit, agglomeration occurred, and the formulation failed. Liqui-Pellet formulation showed an excellent flow, narrow size distribution and was robust to pass friability testing. The key findings in the investigation were that the Liqui-Pellet was capable of a remarkably fast drug release, and 100% drug release achieved within 20 min at pH 1.2, wherein naproxen has been known to be practically insoluble in such pH.

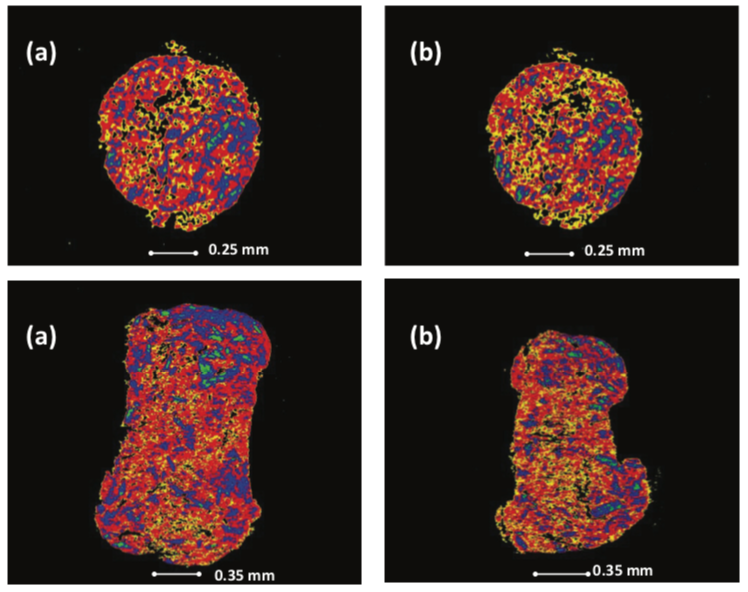

Conclusion: Liqui-Pellets display the potential to enhance explosive dissolution where a combination of effervescent powders and binary carriers with the high surface area were used. Furthermore, X-ray microtomography revealed that the pellets were very uniform and homogenous.

Read more here

Materials: Naproxen, Avicel PH-101, amorphous form of magnesium aluminometasilicate (Neusilin US2), hydrophilic fumed silica (Aerosil 300), primojel, sodium bicarbonate, polysorbate 80