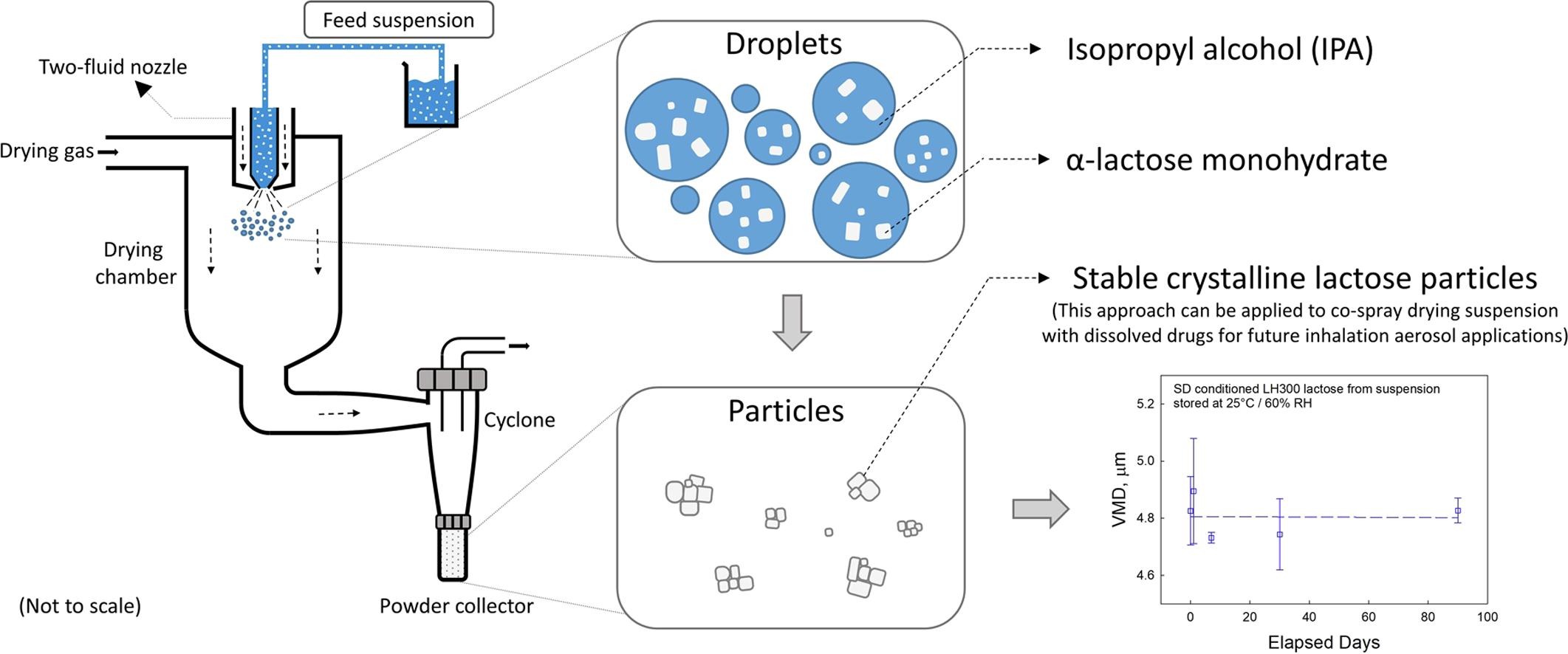

Spray drying lactose from organic solvent suspensions for aerosol delivery to the lungs

Lactose is widely used as an approved excipient for dry powder inhaler (DPI) products. Spray drying technique is a rapid method for converting a liquid feed into inhalable dried particles. However, spray-dried (SD) lactose powders produced from solutions are mostly amorphous and particularly unstable when exposed to moisture. In the present study, we explored the use of spray drying suspensions containing crystalline lactose particles in an organic solvent, and investigated the physicochemical properties of the resulting powders. The solution formulation was spray dried as a control. Two conditioned crystalline lactose samples were used for suspension formulations: Lactohale (LH) 300 lactose and jet-milled (JM) lactose micronized from LH300. The suspension formulations each contained 12 mg/ml suspended crystalline lactose particles (either LH300 or JM lactose) in isopropyl alcohol. The solution formulation contained 60 mg/ml lactose in water. The SD powders were stored under 25 °C/60% RH and 40 °C/75% RH for 3 months. The particulate properties and in vitro dispersion performance were examined at various time points. The SD lactose obtained from solution recrystallized and was no longer dispersible after 1-day storage at both storage conditions. The suspension SD JM lactose powder showed deterioration in the particulate properties and dispersibility over time, but more gradually. In contrast, the SD LH300 powder was stable, with its particulate properties and dispersion performance (FPF: ~12%) remaining the same after 3-months storage at 25 °C/60% RH. The SD LH300 stored at 40 °C/75% RH showed no change in particulate properties, but the FPF decreased over 3 months. Overall, SD lactose powders obtained from suspension demonstrated superior stability performance compared to SD lactose obtained from solution. Continue on Spray drying lactose from organic solvent suspensions for aerosol delivery to the lungs