An Approach to 3D Printing Techniques, Polymer Materials, and Their Applications in the Production of Drug Delivery Systems

Abstract

Three-dimensional printing (3DP) technologies are characterized as a set of innovative manufacturing techniques that allow for the creation of complex and/or personalized three-dimensional physical objects on the work surface of a 3D printing machine (based on the computer-aided design (CAD) project designs of these parts). Three-dimensional printing techniques are widely used in various areas of knowledge, such as education, engineering, and biomedicine. Polymeric materials are widely used for these applications, mainly due to their desirable workability during part manufacturing, compatibility with other chemical materials, the wide range of polymers with different physical and chemical characteristics, and the possibility for recycling. The development of polymeric drug delivery systems (DDSs) by 3D printing is currently an active field of research, both in academia and industry, given the potential of this technique for medical purposes. In this context, this work reviews potential polymers for the production of drug delivery systems via 3D printing techniques. The demonstrations of the main 3DP techniques used for drug delivery applications include their working principles and advantages and how the technologies develop the final product. In addition, potential synthetic and natural polymers that are currently used in 3DP drug delivery devices are presented and discussed based on recent scientific studies.

Introduction

Three-dimensional printing (3DP) techniques are technologies for manufacturing three-dimensional objects based on computer-aided design (CAD) and the deposition of successive layers of a molten material of interest on the flat working surface of a three-dimensional printer [1,2].

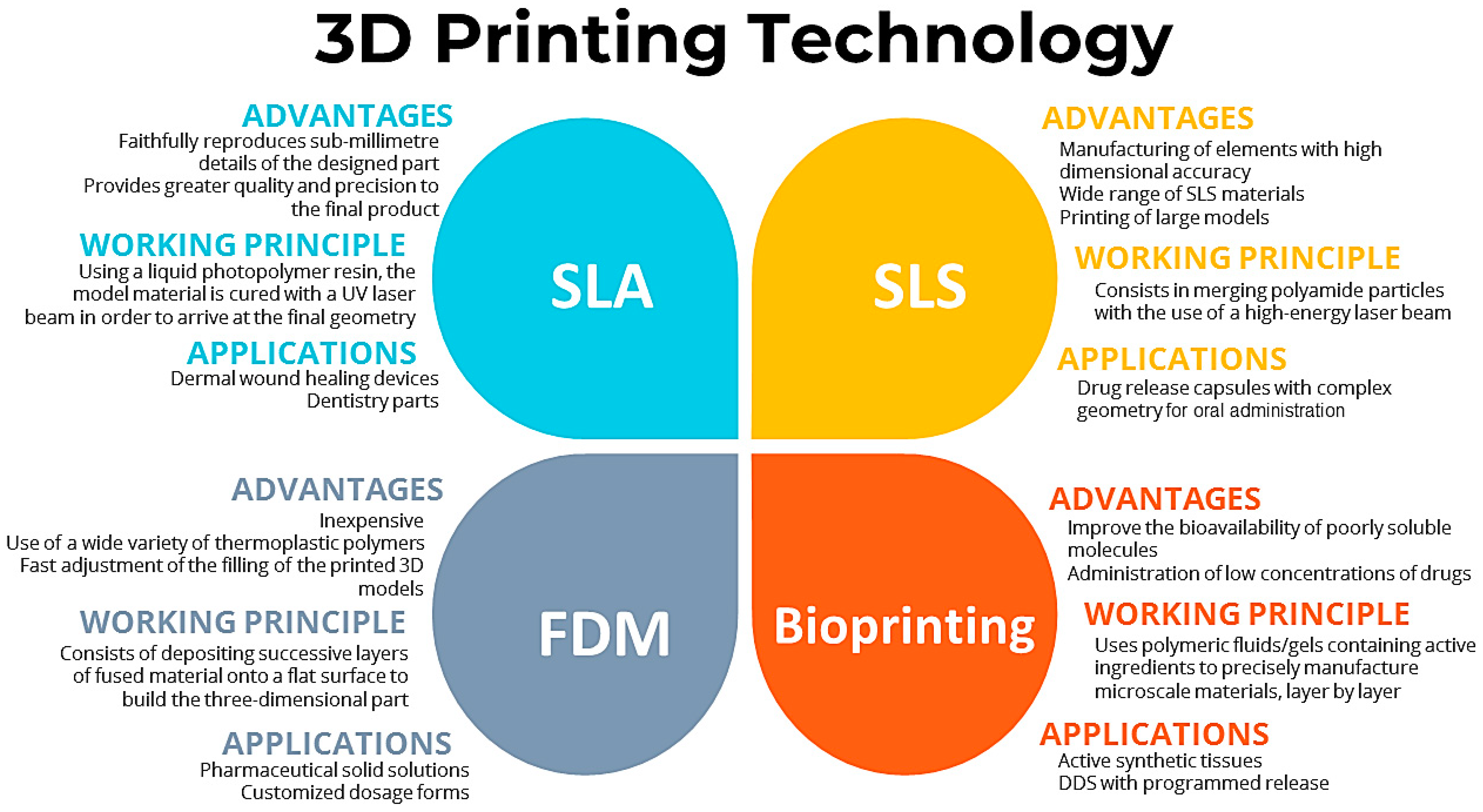

Currently, 3D printing techniques such as fused deposition modeling (FDM), selective laser sintering (SLS), stereolithography (SLA), and bioprinting are among the 3DP technologies that are available for the development of devices in emerging materials science areas, such as in sensors, supercapacitors, flexible circuits, customized biomedical implants, and personalized drug delivery devices [3,4,5,6]. The choice of one of the 3DP techniques for producing a three-dimensional object of interest involves assessing the required properties for the final product and the mode of deposition that is suitable for the production of the designed part [7]. Polymers are the first choice of all materials used in these 3DP technologies, as they are thermoplastic matrices with good compatibility with other chemical materials. The low melting points of these materials increase the manufacturability of the parts, and flexible materials are needed for various applications [8,9,10].

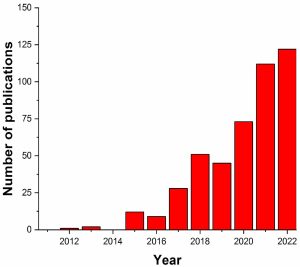

The term drug delivery systems (DDSs) can be understood as a set of methods for transporting drugs within an organism for a specific therapeutic objective [11]. An increasing number of publications on the application of 3DP techniques in combination with polymers for the production of drug delivery systems (DDSs) of active ingredients were published between 2012 and 2022 (Figure 1). The evolution of this research area followed the temporal progress of publications in the 3DP area but still involved a much smaller number of works (compared to the total number of publications: 40,000 works in the same period). This is an indication that 3DP techniques are widely used in various areas of knowledge, from education to engineering, and that the development of polymeric DDSs by 3DP is currently an active field of research, both in academia and industry (given the potential of this technique for biomedical purposes).

For example, the first successful commercial product used in medical printing was Spritam (used in epilepsy treatment), which was authorized in 2015 by the Food and Drug Administration (FDA) of the USA. With the emergence of 3DP medicines, pharmacies can now shift from mass production to the specific dosage forms that are available for patients [12].

In the drug delivery system (DDS) area, the different 3DP techniques allow flexibility in the manufacturing of drug dosage forms (tablets, dermal patches, capsules, and suppositories, among others), which would be difficult to achieve using other forms of pharmaceutical production techniques [13]. These technologies have evolved as novel alternatives to provide personalized DDSs to users, with the aim of facilitating the administration of active substances and obtaining the greatest desirable therapeutic effect [12,14].

Polymers are considered base materials in the production of personalized dosage forms, as these materials can be chosen to modify the release rate of the drug into the medium and provide physical stability for the incorporated drug. The biocompatibility of the polymer is also required for improving pharmacokinetics, reducing side effect interactions with the host tissue, and degrading the device after its action [15]. A biopolymer is preferable for biocompatibility and biodegradability because it does not cause inflammatory reactions in user tissues and does not produce toxic byproducts resulting from degradation [16].

Numerous polymers of synthetic and natural origins are available for application in DDS 3D printing. Synthetic polymers such as polylactic acid (PLA), polyvinyl pyrrolidone (PVP), polyethylene glycol (PEG), polyurethane (PU), and polyvinyl alcohol (PVA) have recently gained attention in this area because of their excellent physicochemical characteristics, cost–benefits, and known interactions with drug molecules [17]. In addition, natural polymers such as chitosan, alginate, gelatin, and collagen are also utilized for the development of novel DDSs by 3DP techniques.

Novel drug delivery systems are being developed using a 3D-printed polymer matrix. Solid dosage forms, implantable drug delivery vehicles, and topical drug delivery systems are the most common applications. Other potential dosage forms include microcapsules, antibiotic micropatterns, synthetic extracellular matrices, mesoporous bioactive glass scaffolds, nanosuspensions, and multilayered DDSs. For example, the development of caplets containing internal gaps, termed gaplets, is intended to increase or decrease the medication release velocity. Owing to their higher surface-area-to-mass ratio, smaller tablets exhibit faster drug release [18]. Similarly, the change in the geometrical shape of a 3DP tablet influences its drug release behavior. In vitro dissolution studies have shown that the ratio of the surface area relative to the volume of 3DP tablets alters the time that is needed for complete drug release [19]. Polymeric gels have also been widely used as materials for 3DP personalized DDSs. Recently, hydrogels have been used as biomaterials in 3D printing, because they can be easily modified without complex synthesis steps to replicate the physicochemical properties of most biological tissues. Hydrogels can exhibit up to 40-fold changes in volume as they swell or shrink in the presence or absence of water, respectively, and can modify the response to various physical and biological stimuli, such as temperature, light, pH, ions, and biochemical signals [20,21].

The development of 3D-printed DDSs has been based on the constant search for new materials/methods, designs, and formulations with the potential for the production of personalized dosage forms. This has resulted in increased interest in drug bioavailability, programmed/controlled action with greater precision in specific regions of the body, and increased drug administration intervals for given medications to improve users’ quality of life [22,23,24].

Based on these aspects, this work presents a bibliographic review of the main 3D printing techniques and polymers that are currently used for the production of novel personalized DDSs for biomedical applications. The theme is presented in detail in the following sections.

Download the full article as PDF here: An Approach to 3D Printing Techniques, Polymer Materials, and Their Applications in the Production of Drug Delivery Systems

or read it here

Materials for 3D Printing discussed in the study beside others: PVA, PVP, PEG, PLGA, Chitosan

Cardoso, P.H.N.; Araújo, E.S. An Approach to 3D Printing Techniques, Polymer Materials, and Their Applications in the Production of Drug Delivery Systems. Compounds 2024, 4, 71-105. https://doi.org/10.3390/compounds4010004

Read more on 3D Printing here: