Use of high melting point solid vegetable oils in encapsulation processes – ADM White Paper

Use of high melting point solid vegetable oils in encapsulation processes

Introduction to encapsulation

Encapsulation relates to technologies that enable the incorporation of a compound into individualized small

particles. Depending on the process applied, these particles can have different sizes, shapes and specific

structures. Many kinds of active compounds can be encapsulated with many different encapsulation materials.

High melting point solid vegetable oils are one of them.

The main objectives for encapsulating an active principle can be classified in 3 major topics [1]:

- Protection / stabilization: encapsulation enables to reduce interactions between the active compound and

the outside environment. High melting point vegetable oils are particularly efficient in protecting active

ingredients against oxygen and water, preventing them from oxidation. - Functionalization / structuration: encapsulation can be very effective in taste, odor and color masking but

also allows to give specific surface properties and rheological characteristics to powders, avoiding dust

formation and promoting an easier handling. It is as well a mean to convert a liquid into a solid form. - Controlled release: depending on the active ingredient to protect and the encapsulation material, it is

possible to fine tune the release profile kinetics upon the action of a selected trigger (temperature, pH, water,

pressure…). [2]

Encapsulation processes using high melting point solid vegetable oils

The general principle of encapsulation is to incorporate an active ingredient within micro particles.

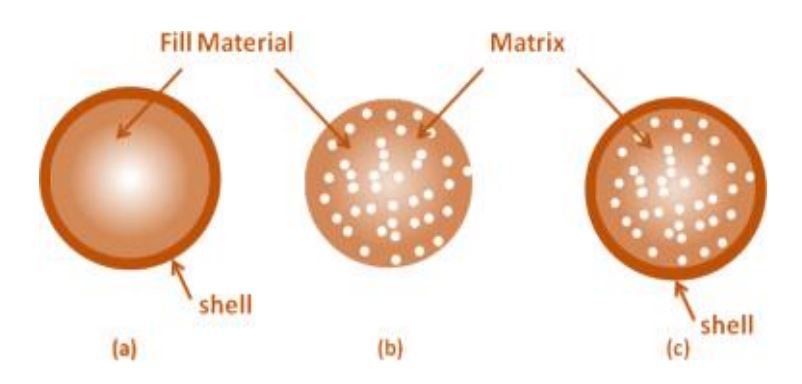

Depending on the technology used, the structure of the particles can be [3]:

• A core / shell structure when the encapsulation material forms a coating around the active ingredient core (a),

• A matrix structure when the active ingredient is dispersed in the encapsulation material (b),

• A combination of both with a matrix core structure coated with a shell (c).

Once the active ingredient is incorporated in the particle, the structure is stabilized. The encapsulation technique is selected based on desired end size, release mechanism, active ingredient and encapsulation material [2]. Among all the different existing encapsulation techniques, high melting point solid vegetable oils are particularly suitable for physical encapsulation processes like prilling and hot melt coating [4].

Pharma

Spray chilling encapsulation technique was used for the first time in the 1960s by Merck and Co Inc. to achieve

taste masking for iron particles and to protect water soluble vitamins. Since that, the importance of lipid-based formulations has increased, due to their outstanding benefits such as providing modified release profiles or taste masking while using solvent-free processing techniques. Active pharmaceutical ingredients are often administered via the oral route. Hot melt coating is especially powerful in masking the unfavorable taste of active pharmaceutical ingredients [16].

Product range

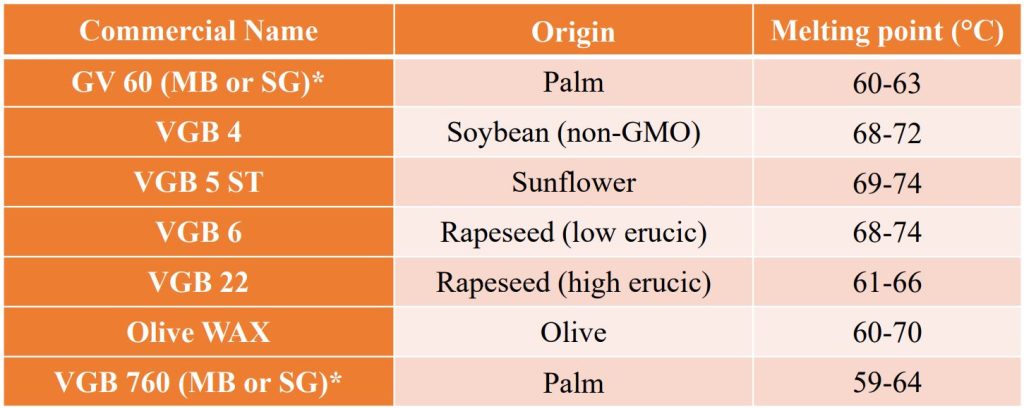

ADM-SIO is a European leader in the production of high melting point flaked fats. Easy to store, handle and dose, they can be either fully hydrogenated or fractionated oils.

* MB (Mass Balance) or SG (Segregated), ADM is member of RSPO (Roundtable for Sustainable Palm Oil)

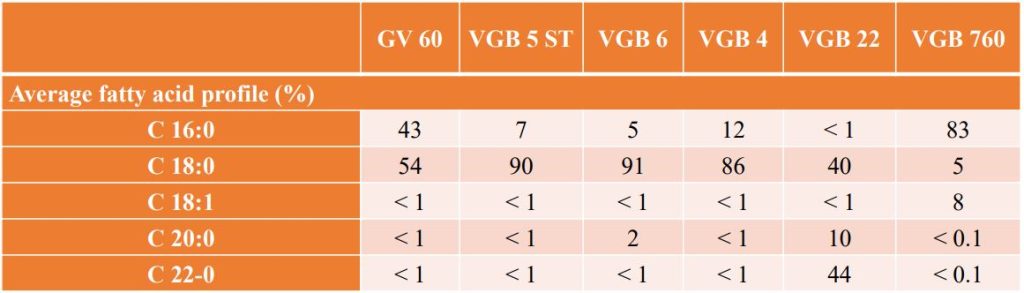

Technical information

Conclusions

Encapsulation techniques with high melting point vegetable oils can be used for a wide range of applications when to ensure protection from oxygen and water, taste masking or controlled release. These techniques are economic, fast, reproducible and safe as they do not need to use any solvent. The selection of the right lipid for the application requires knowledge of their physico-chemical properties, thermal behavior and their associated effect on the bioactive release.

See the ADM white paper: “Use of high melting point solid vegetable oils in encapsulation processes” here

(click the picture to download the brochure)

Source: ADM brochure “ADM White Paper – Use of high melting point solid vegetable oils in encapsulation processes”

ADM Quality & Compliance – From Source to Final Product

With more than a century of experience, dedicated production lines and specialized R&D and regulatory teams, ADM offers its customers innovative global solutions tailored to the specific challenges of the pharmaceutical industry. At ADM, we offer a range of products that meet major relevant pharmaceutical regulations and are manufactured according to appropriate cGMP standards. We make delivering compliance and consistency a reality, giving you an edge to innovate with confidence. We are committed to providing only the purest and highest quality products for your end solutions.

Do you need more information or a sample of ADM excipients?