A Comprehensive Review of Disintegrants: Backbone of disintegration

Abstract

Strong attractive bonding forces works among the particles of solid dosage forms such as mechanical, solid and intermolecular and bioavailability of solid dosage form is preferentially dependent on in vivo disintegration then dissolution. This review is focused for disintegrating agents, their categories, mechanisms of action, associated pros and cons. Furthermore, more emphasis is on natural superdisintegrants, those perform disintegration at fastest rate with limited side effects. So, they are in frequent use to create number of preparations like fast dissolving tablet, pulsatile and tablet dispersible tablet etc. Despite of various disintegrants, superdisintegrants co-processed form of them are thoroughly investigated along with novel techniques of production such as Melt Extrusion, Crystallization, Spray Drying, Solvent Evaporation, Granulation/ Agglomeration.

Introduction

The Although, a variety of dosage forms are available but still oral dosage forms are more preferred by

humankind. As solid dosage forms are compact in structure that make them more acceptable dosage form.

Different bonding forces among solid particles work during the preparation of solid dosage forms, particularly

granules and tablets, to transform them into appropriate dosage forms. The mechanism followed by dominating

bond additionally, surface area across which these bonds are active could be regarded as the two main criteria

for the compactability of powders. These aspects have not been thoroughly assessed for medicinal materials due to significant experimental challenges. Instead, studies and relationships with tablet strength typically focus on

more auxiliary, indirect aspects. Such auxiliary elements as particle form, plastic deformation, surface

roughness, particle size and particle fragmentation, Elastic deformation and have all been examined as important

volume reduction methods [1-4].

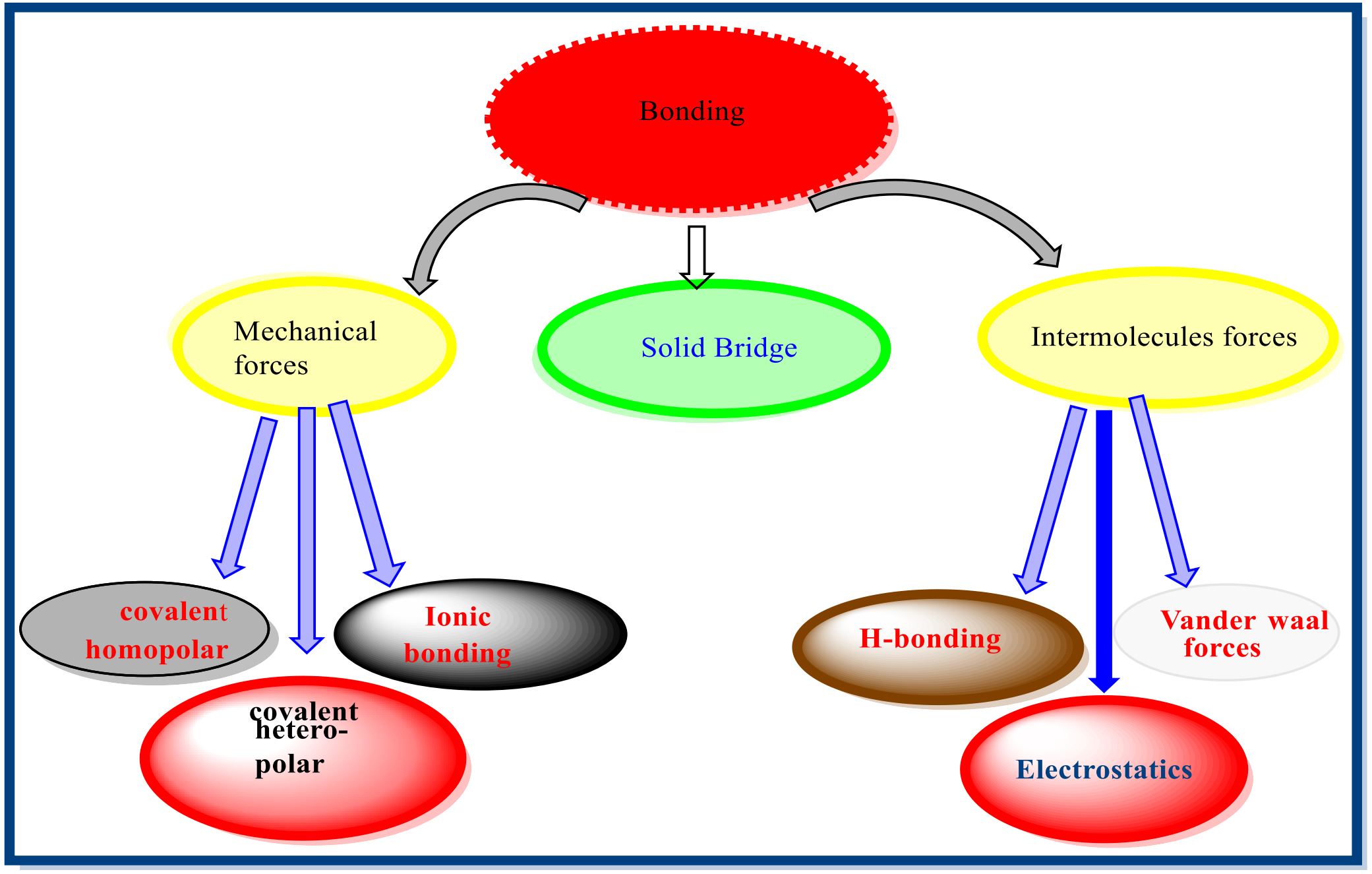

The bonding mechanisms that have been discussed include mechanical interlocking, that represents the bond

kind which dependent on twisting and hooking of uneven particles in shape, solid bridges, which represent

uninterrupted solid bridges between tablet and granules particles, intermolecular forces, which represent infirm

attraction forces active over the distances. Computation of dense strength have been made in media that are

acknowledged to diminish intermolecular forces bonding in order to describe the dominant bond mechanisms.

Liquids with various dielectric constants and films made of magnesium stearate served as the media. The

findings show that the intermolecular forces are the primary type of bonding in medicinal materials. Bonding

with solid bridges can only improve compact strength of particles having coarse nature, plastically deforming

materials that could melt during compaction. Only for coarse plastically deforming materials that can melt

during compaction can bonding with solid bridges help to the compact strength. All bonding shown in (Figure

1).

Only a proportionate connection between the bonding surface area and compact surface area may be feasible for

all materials joining with intermolecular interactions [2]. If the particle surface area in the tablet is big, a huge

bonding surface area for such materials will be obtained. This could be done by using materials that are heavily

fragmented or qualities with noticeable surface roughness or by using very refined particles materials. It is

indicated that the majority of the supposed plastically deforming pharmaceutical materials frequently lack the

flexibility necessary to produce sizable zones that could participate in the attraction of different particles by

different molecules.

Download the full article as PDF here: A Comprehensive Review of Disintegrants: Backbone of disintegration

or read it here

7.2 SUPERDISNTEGRANT’S CATEGORIES

7.2.1 Superdisintegrants Obtained from Nature

Gumseg. Guar Gum, Xanthan Gum, Locust Bean, Cassia Fistula Gum, Karaya Gum,

Gellan Gum.

Agar eg. Gelidiumamansii

Chitosan eg β 2-amino-2-d-glucose

Soy polysaccharide Emcosoy

Superdisintegrants Made Synthetically

Modified starches eg. Sodium Starch Glycolate

Modified cellulose eg. Croscarmellose

Cross-linked poly-vinyl pyrrolidone eg. Crospovidone, polyvinyl-pyrrolidone

Modified Resin eg. Indion 414, Kyron 314

Microcrystalline Cellulose eg. Avicel 102

Cross-linked alginic acid eg. Alginic acid NF

L-substituted Hydroxypropyl derivatives.

Co-processed superdisintegrants

Eg Starlac (maize starch and lactose).

Starcap 1500 (pregelatinized starch and corn starch).

Ran Explo-C (silica, microcrystalline cellulose, and crospovidone).

Ludipress (crospovidone, lactose monohydrate and polyvinylpyrrolidone).

PanExcea MH300G (microcrystalline cellulose, crosspovidone and hydroxyl- propyl- methyl cellulose).

Ran Explo-S (microcrystalline cellulose, sodium starch glycolate and silica).

Following excipients are mentioned in the study besides other: Lycatab® or Sepistab®, Vivapur 101®, silicon dioxide, Polacrilin potassium

Monika Sharma, Amarjeet Singh, Sonia Gupta, Suresh Kumar, Sandeep Kumar and Ankur, A Comprehensive Review of Disintegrants: Backbone of disintegration, Latin American Journal of Pharmacy, Lat. Am. J. Pharm. 43 (1): (2024), ISSN 0326-2383, website http://actafarmbonaerense.com.ar/index.php/latamjpharm/article/view/866

See also our introduction article on Disintegrants: