Real-time in-line prediction of drug loading and release rate in the coating process of diclofenac sodium spheres based on near infrared spectroscopy

Abstract

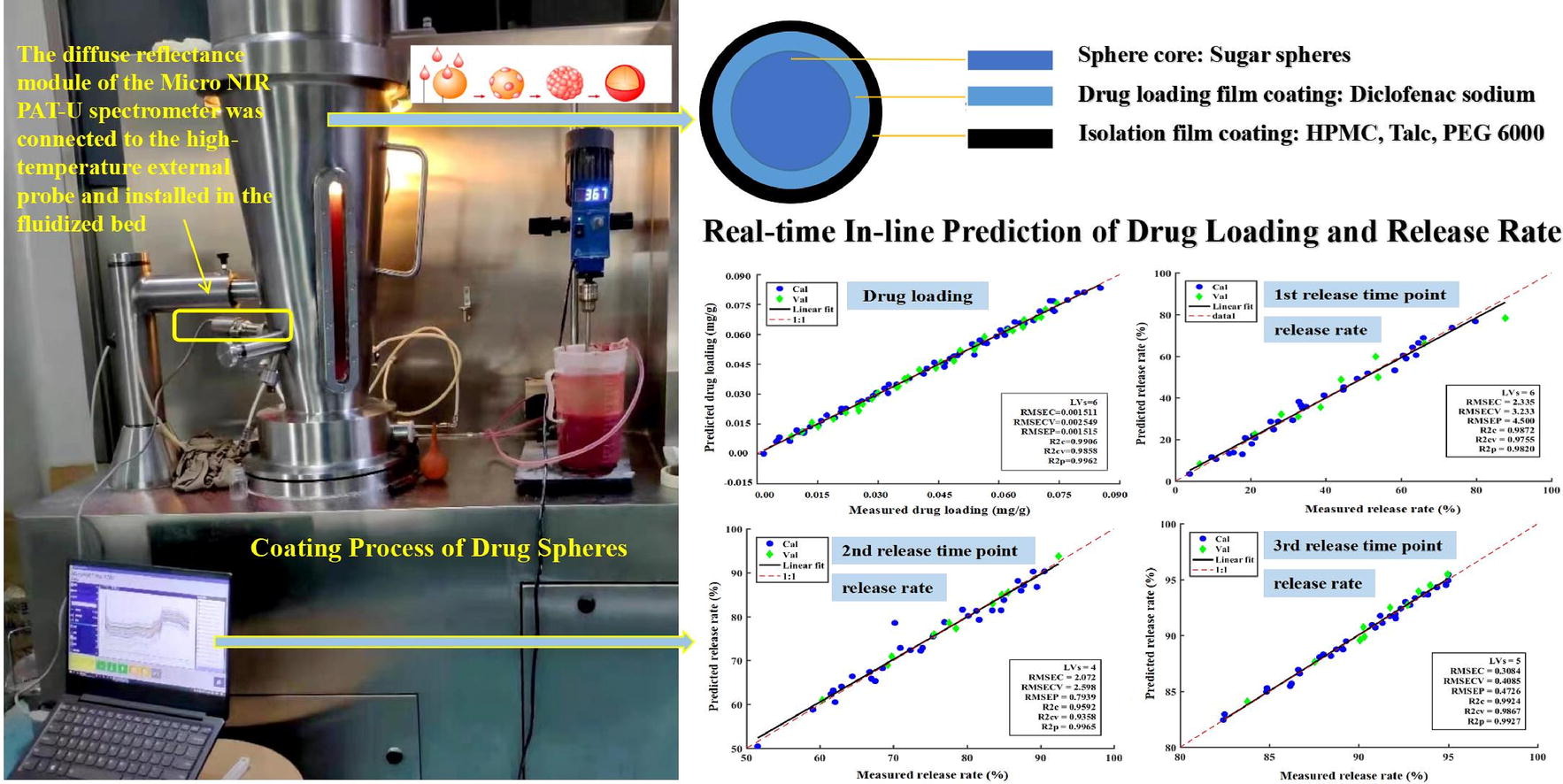

The preparation of diclofenac sodium spheres by fluidized bed is a common production mode for the pharmaceutical preparations at present, but the critical material attributes in the production process is mostly analyzed off-line, which is time-consuming and laborious, and the analysis results lag behind. In this paper, the real-time in-line prediction of drug loading of diclofenac sodium and the release rate during the coating process was realized by using near infrared spectroscopy. For the best near infrared spectroscopy (NIRS) model of drug loading, R2cv, R2p, RMSECV, RMSEP were 0.9874, 0.9973, 0.002549 mg/g, 0.001515 mg/g respectively. For the best NIRS model of three release time points, the R2cv, R2p, RMSECV and RMSEP were 0.9755, 0.9823, 3.233%, 4.500%; 0.9358, 0.9965, 2.598%, 0.7939% and 0.9867, 0.9927, 0.4085%, 0.4726% respectively. And the analytical ability of these model was verified. The organic combination of these two parts of work constituted an important basis for ensuring the safety and effectiveness of diclofenac sodium spheres from the perspective of production process.

Introduction

With the continuous development of new technologies and new materials for pharmaceutical preparations, diclofenac sodium spheres, as a multi-unit film-coated drug delivery system, have gradually become a hot spot in the research of diclofenac sodium preparations due to their good fluidity and stable release rate. As a key process of diclofenac sodium spheres, the coating technologies include rotor fluid bed coating, fluidized bed coating technology, etc. Among them, the fluidized bed coating technology has been widely used in the industrial production of spheres due to its fast heat and mass transfer, small temperature gradient between materials, and large contact area between gas phase and solid phase. The fluidized bed coating technology[1], [2] is achieved by spraying the functional polymer onto the spheres with coating dispersion, and the polymer is generally uniformly coated on the surface of spheres in the form of film coating (Fig. 1). As the critical quality attributes (CQAs) of diclofenac sodium spheres, the drug loading and release rate during coating process need to be emphatically tested and analyzed to ensure the safety and efficacy of spheres in clinical application. At present, the traditional off-line analytical methods are mostly adopted to analyze CQAs, they are time-consuming and laborious, and the analysis results lag behind.

In recent years, process analytical technology (PAT)[3], [4] has attracted much attention in the pharmaceutical industry, and PAT has been applied to pharmaceutical manufacturing. In-line PAT has the following advantages: fast measurement speed, whole process and in-situ nondestructive monitoring, lower cost, environment protecting, researchers had done a lot of work in the field of PAT, such as near infrared spectroscopy (NIRS)[5], [6], [7], [8], Raman[9], optical coherence tomography[10] and so on[11], [12]. PAT had gradually become a powerful means of real-time inline control, and it is also an indispensable monitoring tool under the continuous production mode of the future drugs.

For the production process of coating process, the state of materials is complex. For the coating process, Korasa[13] studied the applicability of the at-line NIRS approach in the monitoring of pellet film coating and curing steps, it was able to determine the extent of the curing and hence predict drug release rate by using partial least square model. Naidu[14] revealed that the developed correlation between the NIRS and cellulose content is useful in precise at-line prediction of functional coat value and can be used for monitoring the Wurster coating process. Barimani[15] used a multivariate analysis method, Science-Based Calibration (SBC) for the first time for endpoint determination of a tablet coating process with Raman data. Lipin[16] propoesed a new model for the batch fluidized bed coating process. Igne[17] studied how sampling practices affected the interpretation of the results provided by a NIRS method for the monitoring of tablet moisture and coating weight gain during a pan-coating experiment. Hudovornik[18] studied the applicability of NIRS and spatial filtering technique (SFT) in the pellet coating process. Silva[19] used Raman spectroscopy, NIRS and focused beam reflectance measurements to monitor the microsphere coating process. Seyedin[20] studied the computational fluid dynamics (CFD) simulation of top spray fluidized bed coating system. The combination of PAT and coating process can achieve the purpose of real-time in-line monitoring the change of product quality during production process and ensuring the consistency of product quality. For the release rate of drug, Galata[21] realized the prediction of the dissolution profile of extended release tablets using NIRS or Raman spectra. In his other research[22], data provided by PAT sensors was combined with critical material attributes to realize the real-time release testing (RTRT) of tablet dissolution.

However, these predecessors rarely carried out real-time in-line prediction study on drug loading and release rate during the coating process[23], and none of literatures achieved real-time in-line prediction of coating thickness and release rate of diclofenac sodium by NIRS at the same time. Process monitoring and control was a very important component to achieving real time release and better process performance and flexibility in manufacturing. The drug loading and release rate are the CQAs of coating process, especially the release rate is an internal index to evaluate the quality of pharmaceutical preparations, and the research on release rate has great significance in effectively controlling the quality of preparations, guiding the optimization of preparation process. Therefore, aiming at the missing part of their work, the preparation process of diclofenac sodium spheres was taken as the experimental object, and the following two parts of experiments were carried out: (1) NIRS was used for the real-time in-line prediction of drug loading of diclofenac sodium during the coating process of sugar spheres. (2) Preliminary study on the application of NIRS in the real-time in-line prediction of release rate during the coating process of diclofenac sodium spheres.

Read more here

Zhongyu Sun, Kefan Zhang, Boran Lin, Ruiqi Huang, Xiangchun Yang, Shuangshuang Li, Mengying Liang, Lei Nie, Wenping Yin, Hui Wang, Hui Zhang, Lian Li, Aoli Wu, Hengchang Zang, Real-time in-line prediction of drug loading and release rate in the coating process of diclofenac sodium spheres based on near infrared spectroscopy, Spectrochimica Acta Part A: Molecular and Biomolecular Spectroscopy, Volume 301, 2023, 122952, ISSN 1386-1425, https://doi.org/10.1016/j.saa.2023.122952.

Visit our new Webinar:

Solving capping challenges using mannitol as an excipient model

Get more information & register here: