Understanding Heat Transfer During the Secondary Drying Stage of Freeze Drying: Current Practice and Knowledge Gaps

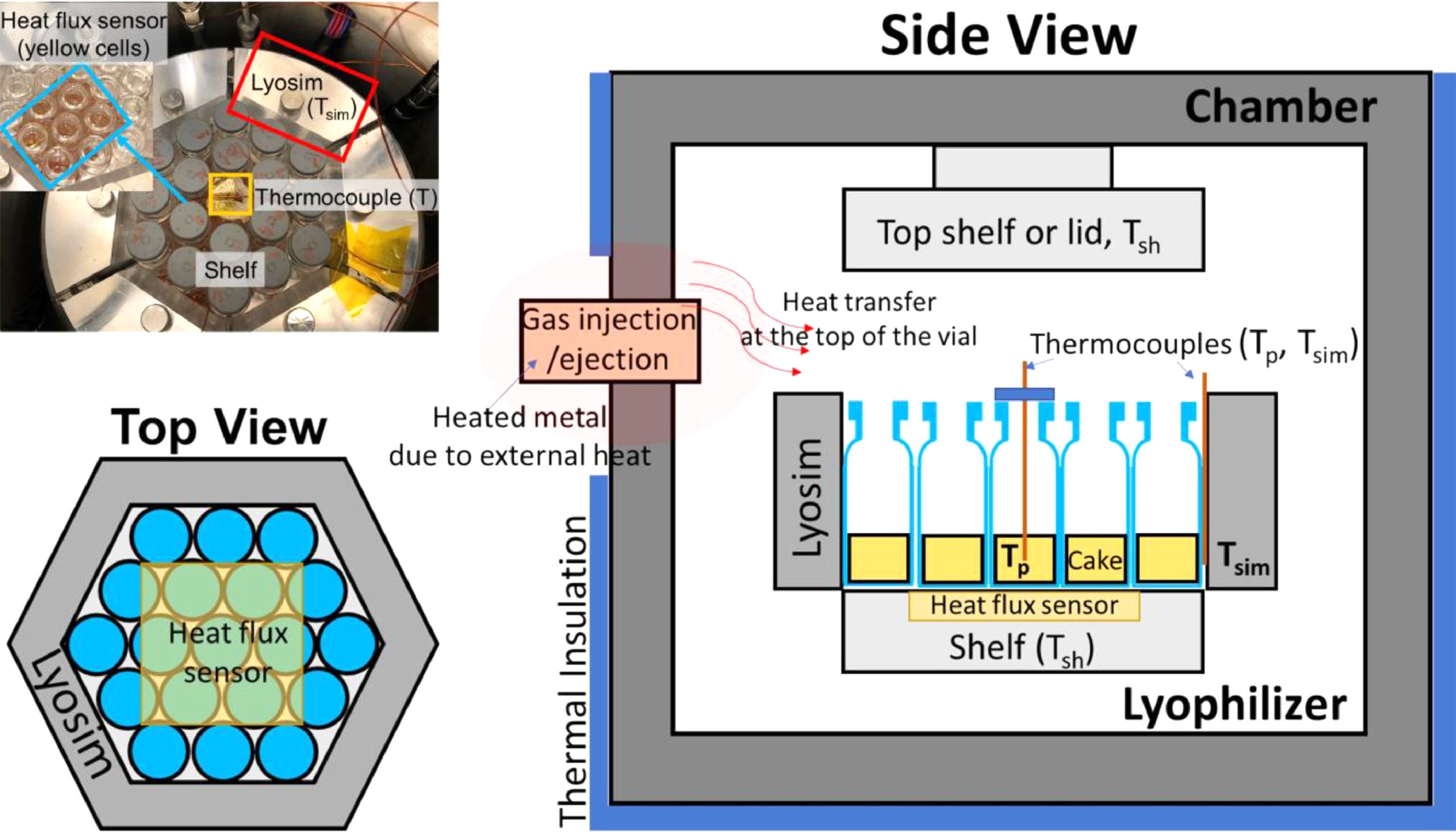

Currently, there is a lack of robust models for secondary drying with comparable accuracy and flexibility as primary drying models. In order to better understand heat transfer during secondary drying, sucrose and mannitol solutions were freeze-dried in vials in a lab-scale lyophilizer under various drying conditions.

Several distinct thermal characteristics for secondary drying were experimentally observed: (1) the vial heat transfer coefficient can change significantly between primary and secondary drying due to the change in water vapor content in the freeze dryer; (2) the thermal mass of the vial plays a major role in determining the cake temperature as roughly 95% of the heat supplied is absorbed by the vial walls. From a theoretical perspective, three different models of secondary drying were examined with varying degrees of complexity (full 3D simulation, 1D-averaged equations, and lumped-capacitance 0D approach).

In these models, the desorption of bound water is treated as a one-way coupling with temperature. It is found that although a simple lumped-capacitance approach can capture many of the vital features of cake temperature and moisture profile, near quantitative agreement with experiments can be made by employing a 1D-averaged equation approach, where the effective thermal conductivities of the vial are determined by thermal circuits.

Download the full article as a PDF here or read it here

Article information: Kyu Yoon, Vivek Narsimhan, Understanding Heat Transfer During the Secondary Drying Stage of Freeze Drying: Current Practice and Knowledge Gaps, Journal of Pharmaceutical Sciences, Volume 111, Issue 2, 2022, Pages 368-381, ISSN 0022-3549, https://doi.org/10.1016/j.xphs.2021.09.032.