Leveraging spray drying technique for advancing biologic product development – A mini review

Over the last 15 years, spray drying (SD), as an alternative to lyophilization, to manufacture and increase the stability of biologics has demonstrated promising outcomes. Pharmaceutical companies, on the other hand, have yet to expand technology for the production of aseptic spray-dried biologics. In this mini-review, we have discussed the limitations and potential of SD in biologics production.

1. Introduction

Protein formulations (PFs) in powder or solid form seemed to be more stable than liquid formulations, therefore having them available in solid powder form increases protein stability. Excipients and dehydration (drying/removing water as a medium for chemical reactions) are the most frequent ways of stabilizing proteins [1]. Freeze-drying (FD) is a commonly used method to convert PFs into powder form [2]. It is the preferred process for drying protein pharmaceuticals, involving freezing the liquid formulation and then removing the ice through sublimation and desorption [3]. The United States Food and Drug Administration (U.S. FDA) has approved more than 400 FD products as of 2014, with an estimated annual growth rate of 13.5% in 2018 [4,5]. Many of these products are protein formulations such as vaccines, antibodies, enzymes, and peptide hormones, which have seen rapid development in recent years [6], [7], [8]. However, despite its advantages, freeze-drying presents challenges such as difficulties in controlling particle and cake properties, variations between vials, processing large quantities of material, and consuming significant power, time, and resources. Consequently, researchers are exploring alternative drying technologies like Spray drying (SD), spray-freezing (SF), and supercritical fluid drying (SFD) to remove water and stabilize biologics [9,10,8].

In the past few years, spray-drying (SD) technology has shown significant effectiveness in the production of certain pharmaceutical formulations. ExuberaVR, an inhaled insulin powder developed by Pfizer, which became the first approved spray-dried hormone in 2006. However, despite its initial approval, ExuberaVR was later withdrawn from the market [11]. Another significant development in the realm of SD-based medications occurred in 2010 with the introduction of Trelstar LA by Verity Pharmaceuticals. Trelstar LA is a suspension of triptorelin pamoate loaded microspheres designed for intramuscular injection. It is primarily utilized in the treatment of hormone-related conditions such as prostate cancer, endometriosis, and precocious puberty [12,13]. Building upon this progress, in 2013, Ispen introduced Somatuline LA, a suspension of lanreotide acetate microspheres. This formulation has proven effective in the treatment of acromegaly, a condition characterized by excessive growth hormone production, as well as certain types of neuroendocrine tumors [14,15]. Another noteworthy milestone in the field of spray-dried biologic formulations occurred in 2015 when RaplixaVR, developed by ProFibrix BV, received approval as the first aseptic spray-dried biologic topical formulation. RaplixaVR, also known as fibrin sealant (human), is used to control bleeding during surgical procedures. In 2018, the FDA was approved INBRIJA, a dry powder formulation of levodopa developed by Acorda Therapeutics Inc. This groundbreaking product enables rapid absorption and quick relief of Parkinson’s symptoms when inhaled directly into the lungs using a specialized inhaler device.

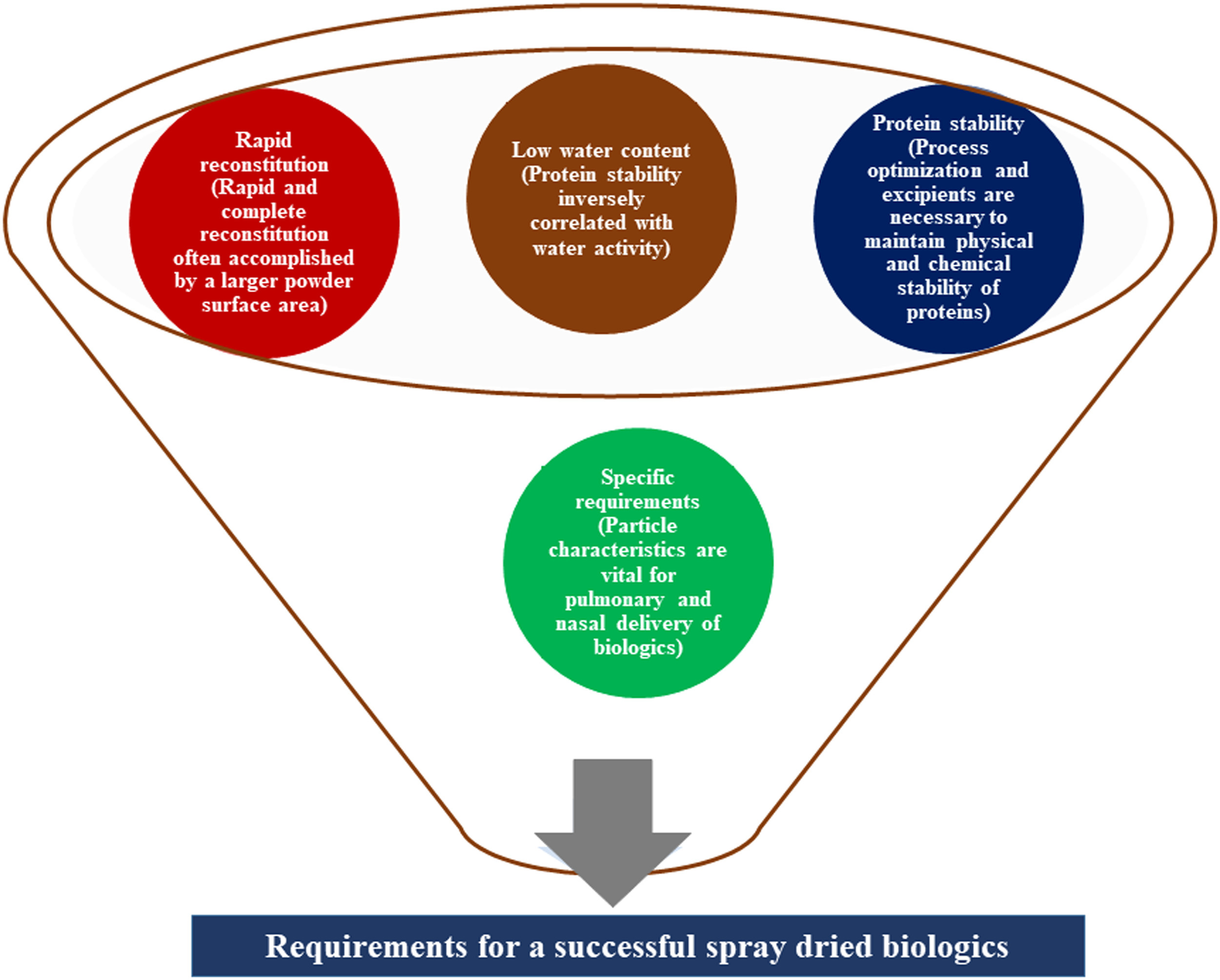

These advancements in SD-based pharmaceuticals have demonstrated the potential of the technology in producing effective and innovative treatment options for various medical conditions [16], [17], [18]. This article provides a concise overview of the SD formulation of biologics as well as the manufacturing problems and stability issues. The requirements for successful spray dried formulation are presented in Figure 1.

6. Excipients to stabilize spray-dried biologics

The main formulation excipients in spray-dried biologics include natural sugars, amino acids, and surfactants. Many disaccharides such as sucrose and trehalose protect proteins in solution from aggregation/inactivation caused by thermal stress [40,41]. The degree of stabilization effect by sugars depends on the sugar concentration and their structure, size, and hydrophobicity. The typical stabilization mechanism of stabilizers is preferential exclusion. The other stabilization mechanism includes excipient interactions with proteins via amino proton, hydrogen bonding, formation of structurally similar hydration sphere to that of a protein, accumulation around specific types of amino acids, and ligand binding [42], [43], [44]. These diverse stabilization mechanisms can exert various effects on proteins by; increasing the thermal unfolding temperature of proteins, improving the colloidal stability of proteins under certain stress conditions, and minimization of protein aggregation [45]. A variety of amino acids have been used in protein stabilization. The amino acids leucine, arginine, glycine, and histidine appear to be the most commonly used. Amino acids can form numerous hydrogen bonds with proteins due to hydrogen bond donors or acceptors, which stabilize proteins. Furthermore, charged amino acids could interact with the oppositely charged side chains electrostatically as well as cation-π interactions with exposed hydrophobic sites [46]. These interactions may promote protein solubility, conformational stability while minimizing protein-protein interactions [47].

Surfactants play a crucial role in structural protection and the prevention of protein aggregation by refolding the protein. The most often utilized surfactants in PFs are polysorbate 20 and polysorbate 80 [21]. Surfactant-mediated protein stability is achieved via two mechanisms: interfacial competition, in which occupancy of surfactant is more favorable than the proteins at the liquid air interface and complex formation via hydrophobic interaction with surfactant is another stabilizing mechanism [27,[48], [49], [50]].

Read more

Mahipal Reddy Donthi, Arun Butreddy, Ranendra Narayan Saha, Prashant Kesharwani, Sunil Kumar Dubey, Leveraging spray drying technique for advancing biologic product development – A mini review, Health Sciences Review, 2023, 100142, ISSN 2772-6320,

https://doi.org/10.1016/j.hsr.2023.100142.