Investigating the impact of air distribution on spray dryer operability using CFD simulations and pilot-scale experiments

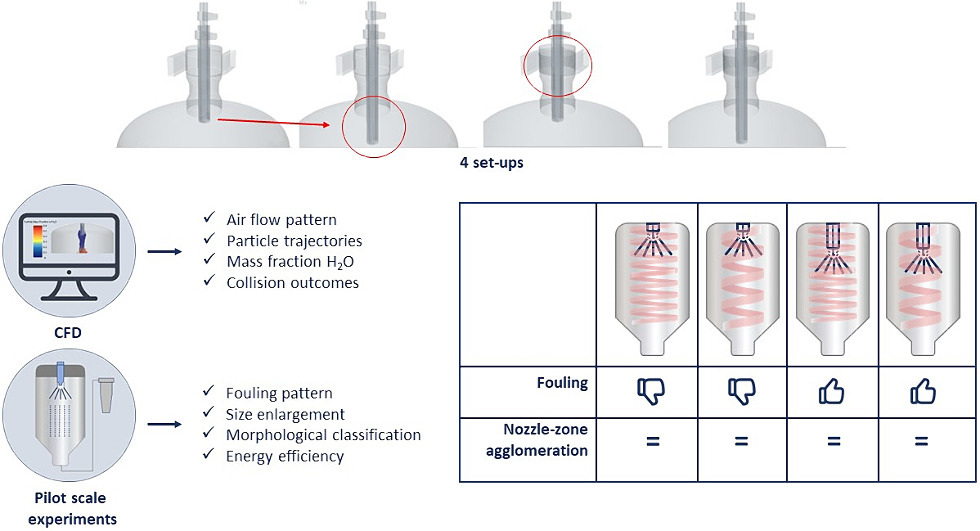

Fouling reduces spray dryer operability. The impact of different configurations of a spray dryer on operability and nozzle-zone agglomeration stimulated by dry powder dosing was investigated through a combination of CFD simulations and pilot-scale experiments. Included were two positions of the nozzle and dry powder introduction, and two degrees of air swirl. Air flows and droplet trajectories were simulated and a particle collision model was built in. The experiments were executed using a single stage co-current spray dryer with concentrical fines return. A high nozzle position (6 cm below the air inlet) resulted in undesired fouling due to an upward air flow causing wet droplets to collide with the roof.

Highlights

- The nozzle position greatly impacts the fouling of a spray dryer.

- A nozzle position close to the hot air inlet causes more fouling Air distribution seems to hardly affect agglomeration in a single stage dryer.

- Upward air flow can explain fouling by conveying wet particles to the dryer’s roof.

The operability was improved by lowering the nozzle position 25 cm as there was less fouling. With a low nozzle position, the degree of air swirl only had a limited effect on fouling. Surprisingly, agglomeration did not seem to be significantly affected by air distribution in both the simulations and the experiments. This means that there is some freedom in the design of a spray dryer in terms of agglomeration. Overall, the findings highlight the importance of well-designed spray drying operations to reduce fouling and thus minimize product waste.

Download the full article as PDF here Investigating the impact of air distribution on spray dryer operability using CFD simulations and pilot-scale experiments

or read it here

Materials

Maltodextrin DE21 (MD21) (Glucidex 21, Roquette Frères, France) was used as model material. Ponceau red E124 (Natural Spices, the Netherlands) was used as colorant. Regular hot tap water (50 °C) was used to prepare the feed.

Anneloes P. van Boven, Arend Dubbelboer, Tom J.A. Janssen, Jewe Schröder, Jos J.W. Sewalt, Reinhard Kohlus, Maarten A.I. Schutyser, Investigating the impact of air distribution on spray dryer operability using CFD simulations and pilot-scale experiments, Powder Technology, 2024, 119779, ISSN 0032-5910, https://doi.org/10.1016/j.powtec.2024.119779.

Watch our recorded webinar to “Spray Drying” here: