MATERIAL CHARACTERIZATION ON STYL’ONE NANO

Particle morphology influence on tablet characteristics

Excipients, APIs or formulations can be processed in different ways, thus resulting in different properties. Research has been performed to improve powder properties including powder flow, powder density, particle size distribution and particle shape.

In the case of tableting, these improvements are crucial to guarantee optimal tablet properties, production yield and high production output.

This case study will illustrate how STYL’One Nano from MEDELPHARM can be an efficient tool for scientists to demonstrate material properties, securing their formulation development and their product marketing.

Crystalline versus spray-dried grades

Mannitol is a polyol widely used in formulations like chewable formulations but also as a filler or a bulk sweetener. It can also be used as replacement in lactose-free formulations. In this example, the effect of mannitol production processes and particle size distribution on tablet properties have been investigated. Two different processes can be used to produce mannitol:

![Spray dried mannitol has been developed to increase and control particle size]() Spray dried mannitol has been

Spray dried mannitol has been

developed to increase and control particle

size and to improve the manufacturability

while maintaining good flowability.![MATERIAL CHARACTERIZATION ON STYL’ONE NANO]() Crystalline mannitol grades are

Crystalline mannitol grades are

typically milled or sieved to obtained

different ranges of particle size.

Fast experiment set-up for comprehensive results

Tableting properties of two grades of spray dried mannitol (100SD and 200SD) and three grades of

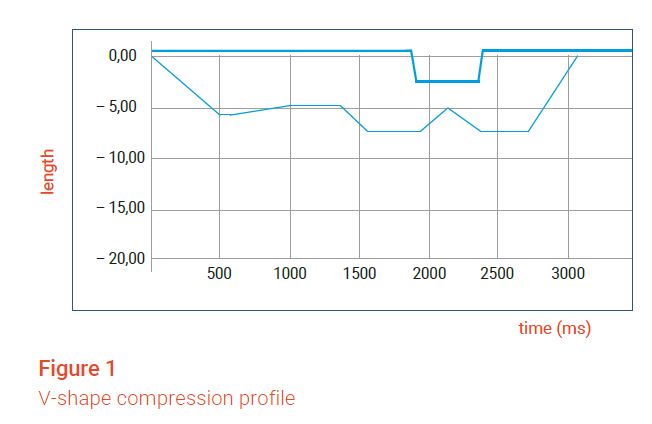

crystalline mannitol (25C, 50C and 160C) have been compared on a STYL’One Nano compaction simulator. Tablets were made at different forces ranging from 5 to 25 kN, using a standard EU-B 11.28-mm round flat tooling and a V-shape research compression profile. V shape profile is often used for material characterization to ensure constant speed of the punch during the compaction process.

Tablet physical properties including weight, dimension and hardness were measured on a Sotax® ST50 and automatically transferred to Alix, the piece of software that drives the STYL’One Nano and analyses the data generated. Alix then computes the data and generates standard and custom charts to accelerate the decision making during pharmaceutical development.

See the full 4 case study on Material Characterization on STYL’ONE NANO here:

(click the picture to download the brochure)

Do you need some details or more information? Just fill in the contact form:

Source: MEDELPHARM brochure “Material Characterization on STYL’ONE NANO”