The impact of material chemistry and morphology on attrition behavior of excipients during high shear blending

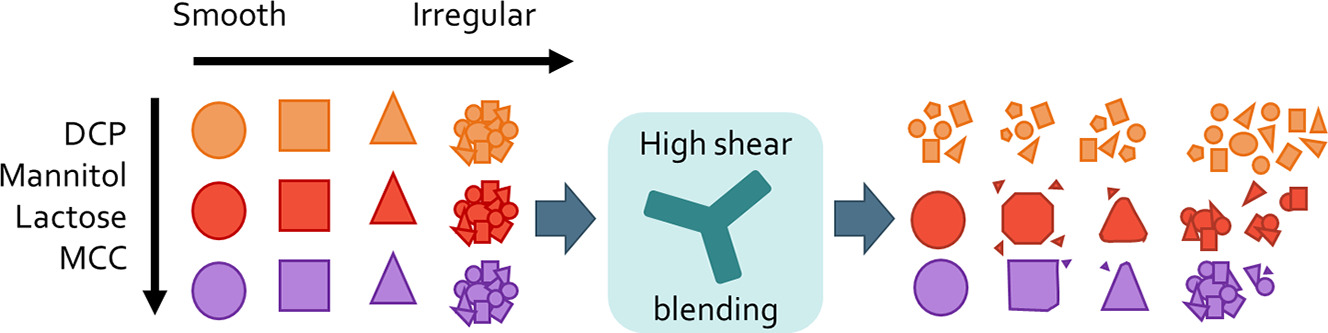

Particle breakage by attrition is unavoidable in some unit operations and can lead to uncontrolled behavior of materials during processing. The aim of this study is to clarify the impact of material properties on attrition behavior. For the first time, an integral study with varying morphologies and chemistries is performed to identify the key drivers that impact attrition during high shear blending. Based upon the observed changes in particle size distribution, it was concluded that dicalcium phosphate (DCP) was the most prone to attrition, followed by mannitol, lactose and microcrystalline cellulose (MCC).

Highlights

Attrition during high shear blending depends on chemistry and morphology.

- Changes in particle size were quantified for different excipients after blending.

- Brittle deforming material shows more attrition than plastic deforming material.

- Smooth morphologies are more prone to attrition than irregular morphologies.

- Impact of attrition on functionality differs per material.

Granular particles were more sensitive to attrition than sieved and spherical particles. Changes in bulk density, flow function coefficient and tablet tensile strength were observed as the result of attrition. The magnitude and direction of change in these parameters was not only dependent on the amount of attrition, but also on the morphology and the material deformation properties.

Tablet 1. Overview of the twelve excipients used in this study. For each excipient, the chemistry, morphology, abbreviation (abbr.) and the supplier is indicated.

| Name | Chemistry | Morphology | Abbr. | Supplier |

|---|---|---|---|---|

| SuperTab® 24AN | Lactose Anhydrous (LA) | Granular (g) | LAg | DFE Pharma (Goch, Germany) |

| SuperTab® 30GR | Lactose Monohydrate (LM) | LMg | ||

| SuperTab® 40LL | Co-processed Lactose-Lactitol (LL) | LLg | ||

| Mannogem® Granular | Mannitol (M) | Mg | SPI Pharma (Wilmington, USA) | |

| Di-cafos A150 | Dicalcium phosphate anhydrate (DA) | DAg | Budenheim KG (Budenheim, Germany) |

|

| Di-cafos D160 | Dicalcium phosphate dihydrate (DD) | DDg | ||

| SuperTab® 21AN | Lactose Anhydrous (LA) | Sieved (s) | LAs | DFE Pharma (Goch, Germany) |

| Pharmatose® 100 M | Lactose Monohydrate (LM) | LMs | ||

| SuperTab® 11SD | Lactose Monohydrate (LM) | LMsd | DFE Pharma (Goch, Germany) | |

| Pharmacel® 102 | Microcrystalline cellulose (MCC) | Spray dried (sd) | MCCsd | |

| Pharmacel® sMCC 90 | Co-spray dried Silicified microcrystalline cellulose (SMCC) | SMCCsd | ||

| Mannogem® XL Opal | Mannitol (M) | Msd | SPI Pharma (Wilmington, USA) |

Download the full article as PDF here The impact of material chemistry and morphology on attrition behavior of excipients during high shear blending

or read it here

Sri Sharath Kulkarni, Pauline H.M. Janssen, Bastiaan H.J. Dickhoff, The impact of material chemistry and morphology on attrition behavior of excipients during high shear blending, Powder Technology, 2023, 118694, ISSN 0032-5910, https://doi.org/10.1016/j.powtec.2023.118694.

Visit our new Webinar:

Solving capping challenges using mannitol as an excipient model

Get more information & register here: