Fabrication and Characterization of Orodispersible Composite Film from Hydroxypropylmethyl Cellulose-Crosslinked Carboxymethyl Rice Starch

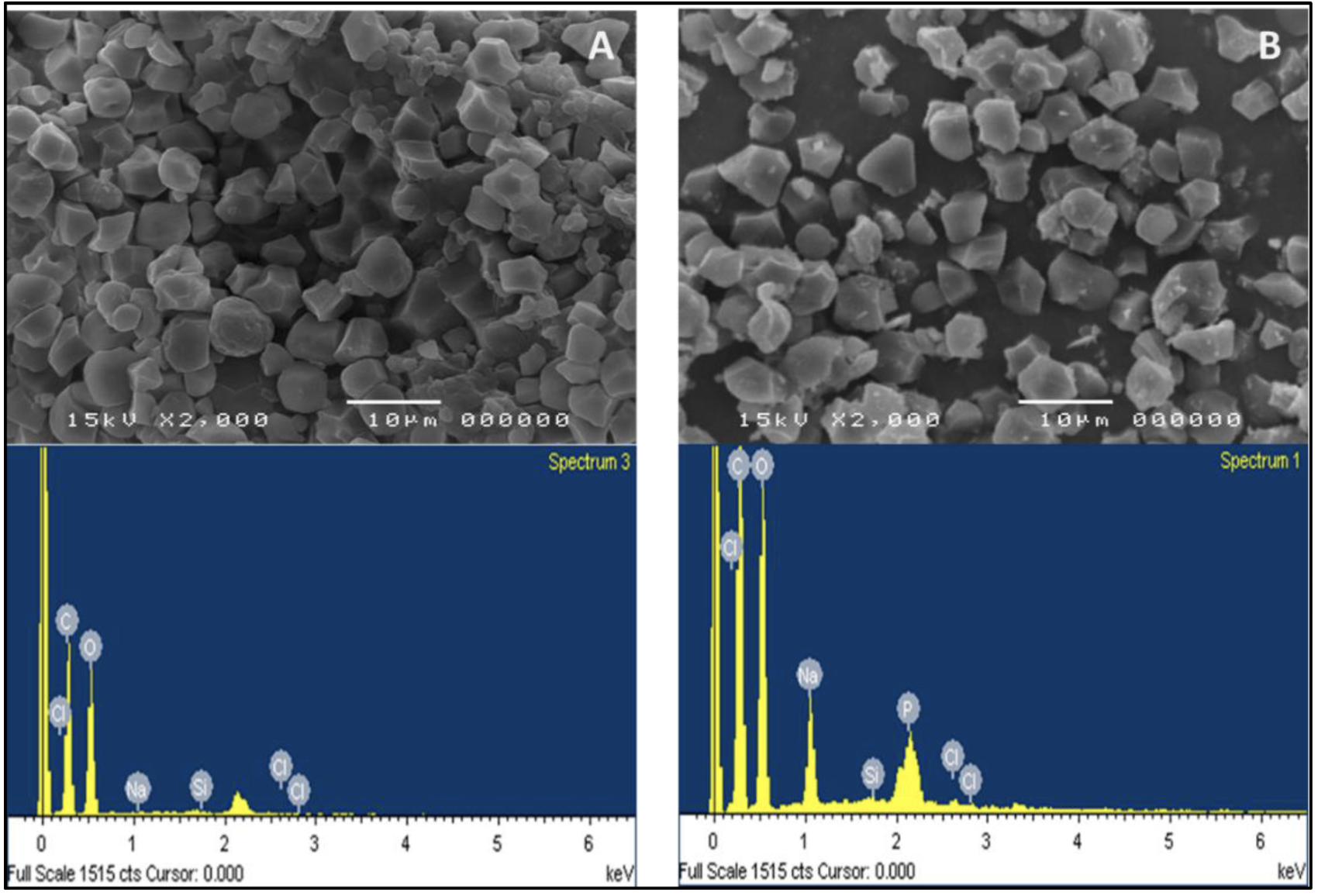

Crosslinked carboxymethyl rice starch (CLCMRS), prepared via dual modifications of native rice starch (NRS) with chloroacetic acid and sodium trimetaphosphate, was employed to facilitate the disintegration of hydroxypropylmethylcellulose (HPMC) orodispersible films (ODFs), with or without the addition of glycerol. Fabricated by using the solvent casting method, the composite films, with the HPMC–LCMRS ratios of 9:1, 7:1, 5:1 and 4:1, were then subjected to physicochemical and mechanical evaluations, including weight, thickness, moisture content and moisture absorption, swelling index, transparency, folding endurance, scanning electron microscopy, Fourier transform infrared spectroscopy, tensile strength, elongation at break, and Young’s modulus, as well as the determination of disintegration time by using the Petri dish method (PDM) and slide frame and bead method (SFM). The results showed that HPMC-CLCMRS composite films exhibited good film integrity, uniformity, and transparency with up to 20% CLCMRS incorporation (4:1 ratio). Non-plasticized composite films showed no significant changes in the average weight, thickness, density, folding endurance (96–122), tensile strength (2.01–2.13 MPa) and Young’s modulus (10.28–11.59 MPa) compared to HPMC film (135, 2.24 MPa, 10.67 MPa, respectively). On the other hand, the moisture content and moisture absorption were slightly higher, whereas the elongation at break (EAB; 4.31–5.09%) and the transparency (4.73–6.18) were slightly lowered from that of the HPMC film (6.03% and 7.03%, respectively). With the addition of glycerol as a plasticizer, the average weight and film thickness increased, and the density decreased. The folding endurance was improved (to >300), while the transparency remained in the acceptable range. Although the tensile strength of most composite films decreased (0.66–1.75 MPa), they all exhibited improved flexibility (EAB 7.27–11.07%) while retaining structural integrity. The disintegration times of most composite films (PDM 109–331, SFM 70–214 s) were lower than those of HPMC film (PDM 345, SFM 229 s). In conclusion, the incorporation of CLCMRS significantly improved the disintegration time of the composite films whereas it did not affect or only slightly affected the physicochemical and mechanical characteristics of the films. The 5:1 and 4:1 HPMC:CLCMRS composite films, in particular, showed promising potential application as a film base for the manufacturing of orodispersible film dosage forms.

Continue reading here

About this article: Kittipongpatana, Ornanong S., Karnkamol Trisopon, Phanphen Wattanaarsakit, and Nisit Kittipongpatana. 2022. “Fabrication and Characterization of Orodispersible Composite Film from Hydroxypropylmethyl Cellulose-Crosslinked Carboxymethyl Rice Starch” Membranes 12, no. 6: 594. https://doi.org/10.3390/membranes12060594

Materials

Native rice starch (RS) (Lot no. 709161) was purchased from Thai Flour Industry Co., Ltd. (Bangkok, Thailand). Monochloroacetic acid (MCA, CAS No. 79-11-8, Product Code 8004121000) was purchased from Merck (Hohenbrunn, Germany). Sodium trimetaphosphate (STMP, CAS No. 7785-84-4, Product Code 1001229448) was supplied by Aldrich (IL, USA). Hydroxypropyl methylcellulose (Methocel E5LV Premium) was supplied by Rama Production Co.Ltd. (Bangkok, Thailand).