Effect of particle size on the dispersion behavior of magnesium stearate blended with microcrystalline cellulose

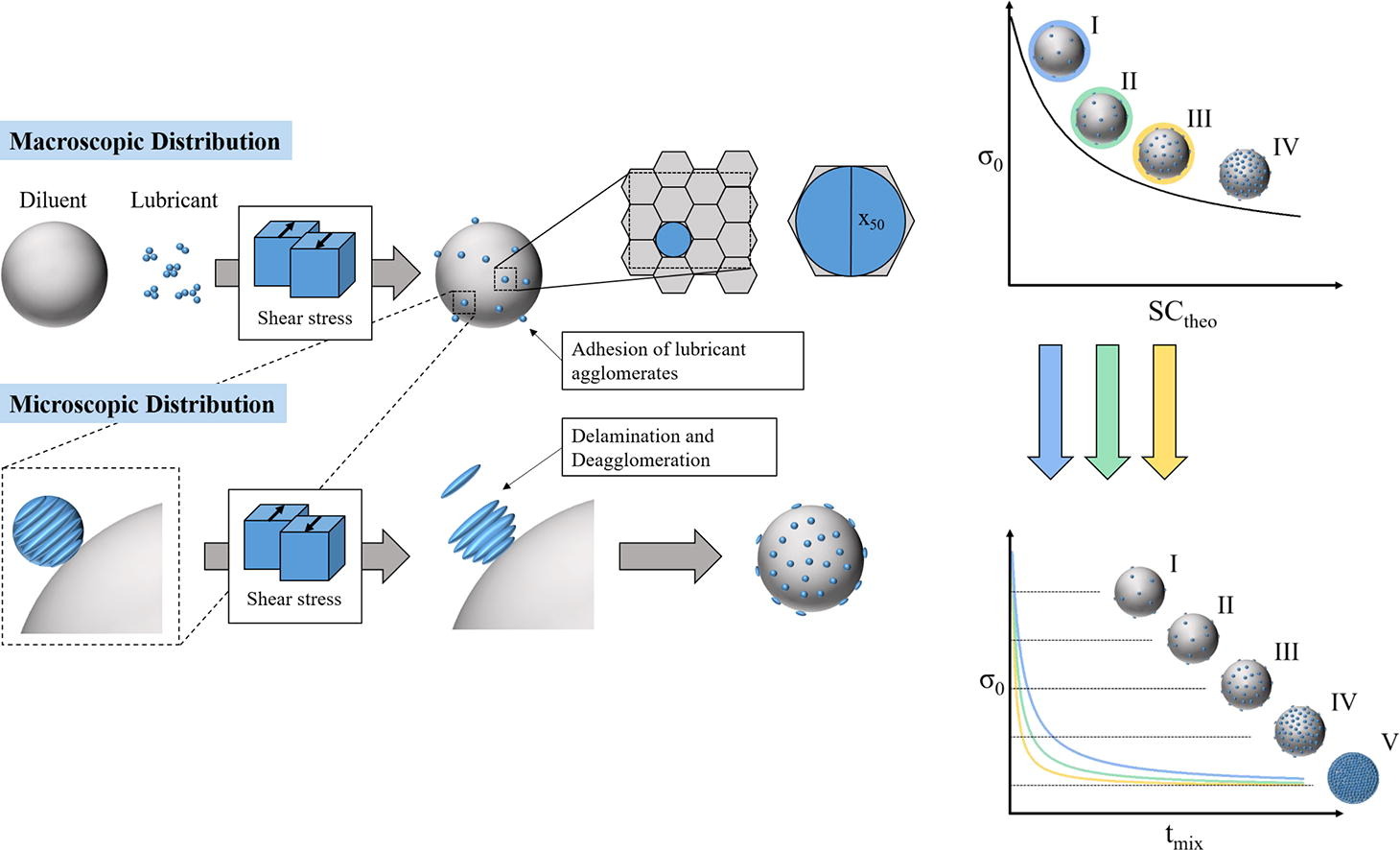

The majority of tablets manufactured contain lubricants to reduce friction during ejection. However, especially for plastically deforming materials, e.g., microcrystalline cellulose (MCC), the internal addition of lubricants is known to reduce tablet tensile strength. This reduction is caused by the surface coverage by lubricant particles, the extent of which depends on both process and formulation parameters. Previously published models to predict the lubrication effect on mechanical strength do not account for changes in the excipient particle size.

In this study, the impact of both lubricant concentration and mixing time on the tensile strength of tablets consisting of three different grades of MCC and four grades of magnesium stearate (MgSt) was evaluated. By taking into account the particle size of the applied excipients, a unifying relationship between the theoretically estimated surface coverage and compactibility reduction was identified. Evaluating the dispersion kinetics of MgSt as a function of time reveals a substantial impact of the initial surface coverage on the dispersion rate, while the minimal tensile strength was found to be comparable for the majority of formulations. In summary, the presented work extends the knowledge of lubricant dispersion and facilitates the reduction of necessary experiments during the development of new tablet formulations.

2.8. Materials

Three different grades of microcrystalline cellulose (Vivapur 101 (MCCfine), Vivapur 102 (MCCmedium) and Vivapur 200 (MCCcoarse), all JRS Pharma, Germany) were considered in this study. For lubrication, four different grades of magnesium stearate (Carl Roth, Germany (MgSt1); Faci, Italy (MgSt3); Ligamed MF-2-V, Peter Greven GmbH, Germany (MgSt2); Ligamed MF-3-V, Peter Greven GmbH, Germany (MgSt4)) were used. Prior to application, lubricants were deagglomerated by using a 355 µm sieve.

The morphology and particle size of the investigated lubricants were investigated by means of SEM images. The nomination of MgSt grades follows their median particle size (cf. Figure 1 and Figure 2b). MgSt2, MgSt3, and MgSt4 exhibit a comparable particle morphology in which the platelet-shaped primary particles are agglomerated into coarser secondary particles. It is generally believed that during blending processes, acting shear stress results in the dispersion of these primary lubricant particles for prolonged mixing times (Shah and Mlodozeniec, 1977, Badal Tejedor et al., 2015). In contrast, MgSt1 consists of considerably larger primary particles, which showed a limited surface roughness to which smaller particles are attached. Generally, all investigated MgSt grades exhibit a monomodal particle size distribution whereby the median particle size ranges between 17.2 µm (MgSt1) and 6.9 µm (MgSt4) (Table 1 and Figure 2).

Download the full study (Pre-proof) as PDF here: Effect of particle size on the dispersion behavior of magnesium stearate blended with microcrystalline cellulose – Pre-proof

or read it here

Daniel Puckhaber, Jan Henrik Finke, Sarah David, Bindhumadhavan Gururajan, Supriya Rane, Arno Kwade, Effect of particle size on the dispersion behavior of magnesium stearate blended with microcrystalline cellulose, International Journal of Pharmaceutics, 2024, 123792, ISSN 0378-5173,

https://doi.org/10.1016/j.ijpharm.2024.123792.

See also our introduction article on magnesium stearate: