Pharma 4.0-Artificially Intelligent Digital Twins for Solidified Nanosuspensions

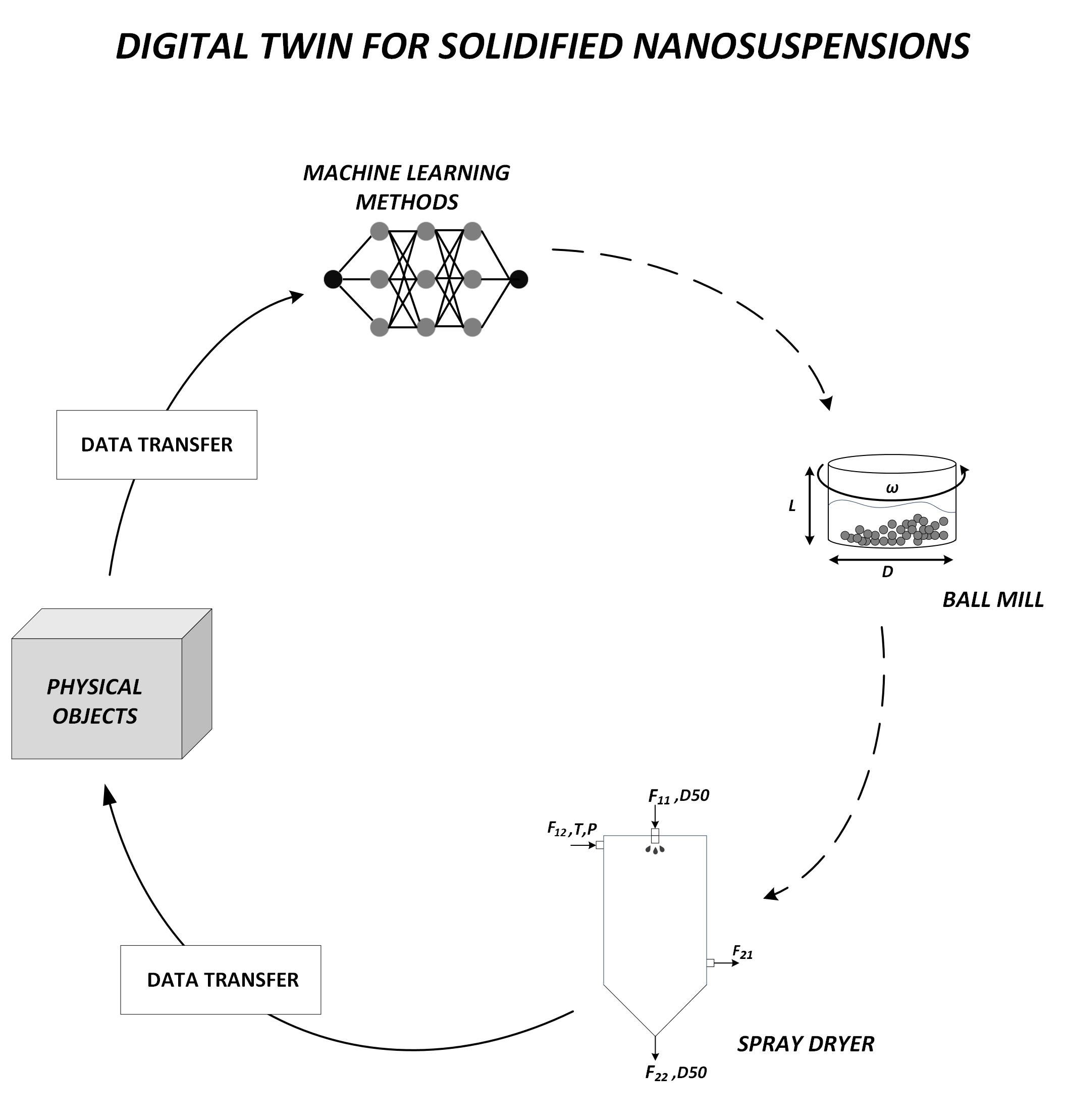

Digital twins capacitate the industry 4.0 paradigm by predicting and optimizing the performance of physical assets of interest, mirroring a realistic in-silico representation of their functional behaviour. Although advanced digital twins set forth disrupting opportunities by delineating the in-service product and the related process dynamic performance, they have yet to be adopted by the pharma sector. The latter, currently struggles more than ever before to improve solubility of BCS II i.e., hard-to-dissolve active pharmaceutical ingredients by micronization and subsequent stabilization. Herein we construct and functionally validate the first artificially intelligent digital twin thread, capable of describing the course of manufacturing of such solidified nanosuspensions given a defined lifecycle starting point and predict and optimize the relevant process outcomes. To this end, we referenced experimental data as the sampling source, which we then augmented via pattern recognition utilizing neural network propagations. The zeta-dynamic potential metrics of the nanosuspensions were correlated to the interfacial Gibbs energy, while the density and heat capacity of the material system was calculated via the Saft-γ-Mie statistical fluid theory. The curated data was then fused to physical and empirical laws to choose the appropriate theory and numeric description, respectively, before being polished by tuning the critical parameters to achieve the best fit with reality.

Download the full article as PDF here Pharma 4.0-Artificially Intelligent Digital Twins for Solidified Nanosuspensions

or read it here

Davidopoulou, C.; Ouranidis, A. Pharma 4.0-Artificially Intelligent Digital Twins for Solidified, Nanosuspensions. Pharmaceutics 2022, 14, 2113. https://doi.org/10.3390/pharmaceutics14102113