Investigating the Role of Excipients on the Physical Stability of Directly Compressed Tablets

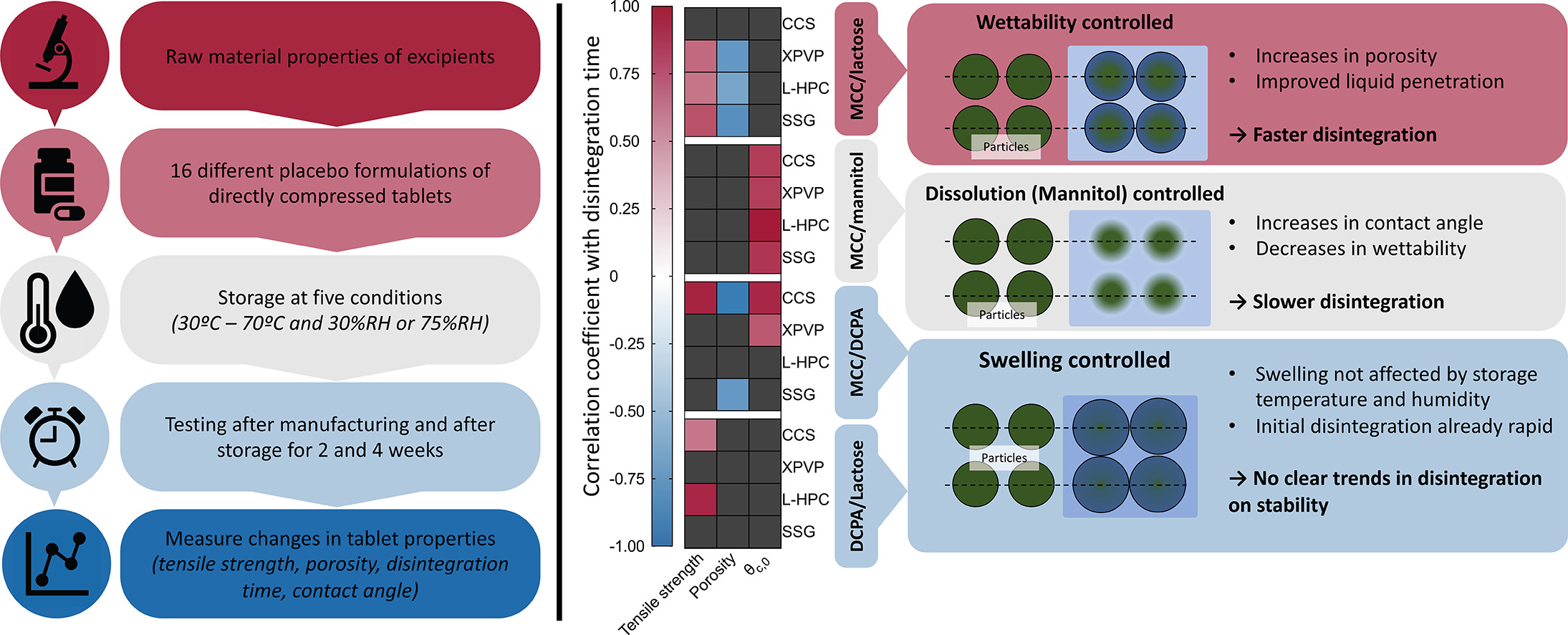

Stability studies are an integral part of the drug development process for any drug product. In addition to monitoring chemical degradation, the physical stability of a drug product must also be evaluated to ensure that the drug release and performance is not affected by storage. In this study, directly compressed tablets of 16 different formulations were exposed to an accelerated stability program to quantify changes in tablet breaking force, porosity, contact angle and disintegration time.

Tablets were exposed to five different storage conditions from 37∘C/30% relative humidity (RH) to 70∘C/75%RH with testing after 2 and 4 weeks of storage. Each formulation contained two different fillers (47% w/w each), a disintegrant (5% w/w) and magnesium stearate (1% w/w). The results show that tablets stored at high humidity show increases in porosity and decreases in tensile strength, particularly if they contain a highly hygroscopic filler such as microcrystalline cellulose (MCC).

For tablets stored at high temperature, the most commonly affected property was the tablet wettability, measured by sessile drop contact angle measurements. These results are considered in combination with the performance-controlling disintegration mechanism (Maclean et al., 2021) to identify the critical properties which influence the performance after storage.

Download the full article as a PDF here or read it here

Materials: Tablet excipients included microcrystalline cellulose (MCC) (Avicel®PH-102, FMC International), mannitol (Pearlitol®200 SD, Roquette), lactose (FastFlo®316, Foremost Farms USA) and dibasic calcium phosphate anhydrous (DCPA) (Anhydrous Emcompress, JRS Pharma) as fillers. The disintegrants croscarmellose sodium (CCS) (FMC International), crospovidone (XPVP) (Kollidon®CL, BASF), low-substituted hydroxypropyl cellulose (L-HPC) (LH-21, Shin-Etsu Chemical Co.) and sodium starch glycolate (SSG) (Primojel®, DFE Pharma) were used in the tablet formulations. Magnesium stearate (Mallinckrodt) was used as a lubricant. Magnesium chloride and sodium chloride (Sigma Aldrich) were used to make saturated salt solutions.

Article information: Natalie Maclean, Ibrahim Khadra, James Mann, Helen Williams, Alexander Abbott, Heather Mead, Daniel Markl, Investigating the Role of Excipients on the Physical Stability of Directly Compressed Tablets, International Journal of Pharmaceutics: X, 2021. https://doi.org/10.1016/j.ijpx.2021.100106.