A systematic investigation of external lubrication of mini-tablets on a rotary tablet press with focus on the tensile strength

Abstract

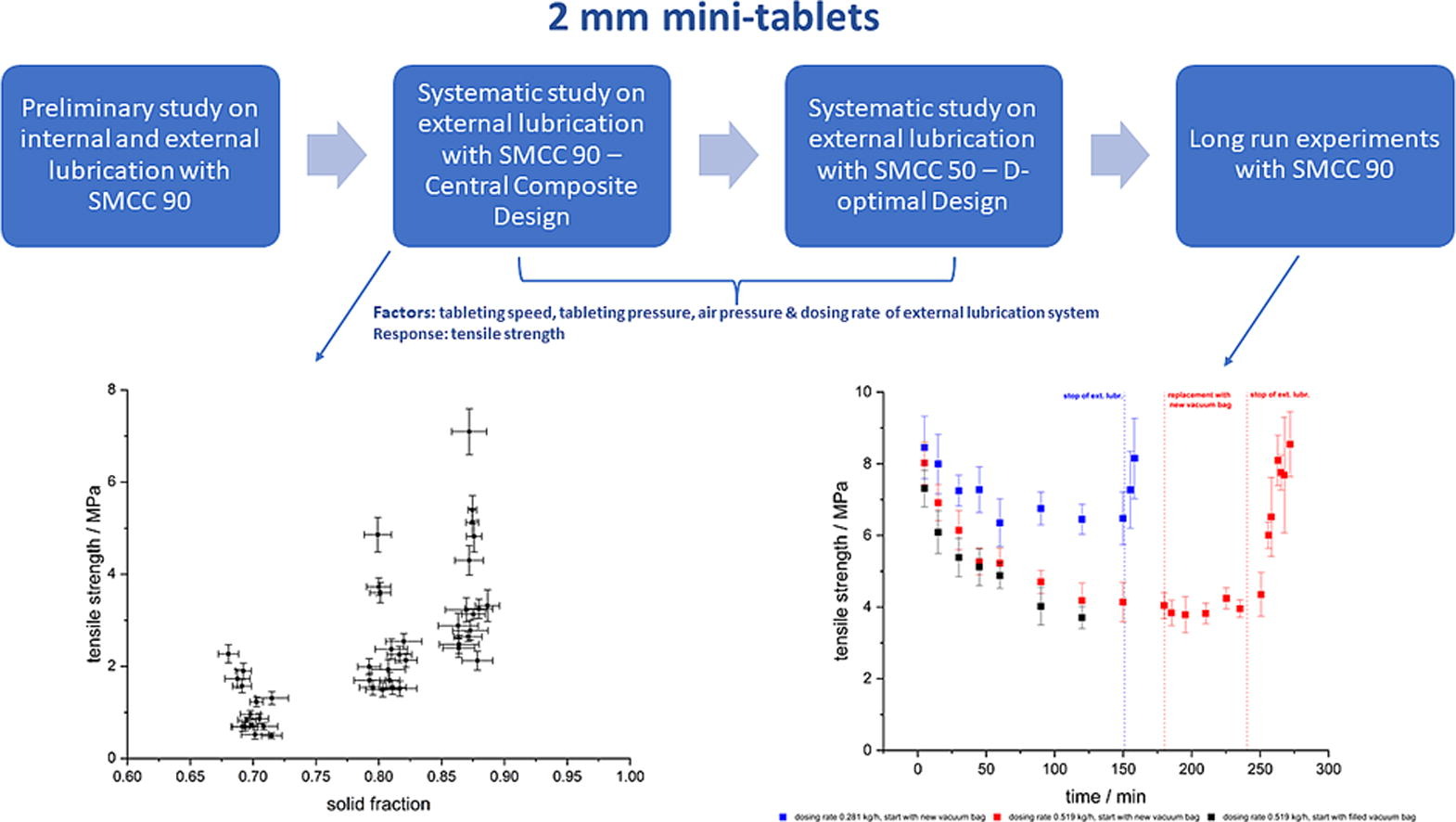

External lubrication is an alternative to internal lubrication and its related detrimental effects on properties of tablets like tensile strength (TS). However, to date there are hardly any systematic investigations on external lubrication of mini-tablets on rotary tablet presses. Aim of this study was the systematic investigation of the impact of parameters tableting pressure, tableting speed, dosing rate and air pressure on the TS of mini-tablets. Both studies, the Central Composite Design (CCD) with SMCC 90 and the subsequently executed D-optimal design with SMCC 50, exhibited that tableting pressure had the highest positive effect on TS. Tableting speed and dosing rate in the CCD presumably did not seem to influence the TS, air pressure represented a positive coefficient. An additional temporal factor seemed to impact the results, deduced from the negative effect of the experimental order on TS in the CCD and from the negative correlation along the execution order in the residual plots. Additional long runs support findings of a non-linear decrease of TS over time. An interplay between dosing rate level and performance of the dust extraction collector is assumed, making more magnesium stearate available in the tablet press and potentially causing gradual contamination of the powder over time.

Introduction

Mini-tablets with a diameter equal or less than 3 mm and a surface-to-volume ratio of at least 2 mm−1 [1], [2] are becoming increasingly important in the paediatric field. Various studies have already displayed acceptability and swallowability of single and multiparticulate mini-tablets for paediatrics [3], [4], [5], [6], [7].

In the industrial development and manufacturing of tablets regardless of size lubrication plays a pivotal role. For conventionally sized tablets, there are numerous publications addressing internal and external lubrication. Use of a lubricant in the formulation reduces friction between the die walls and tablet and consequently also the ejection force during the ejection step [8], [9], [10], thereby alleviating problems such as sticking to punches, capping or lamination of tablets. The reduction of wear of the tooling is also a relevant aspect [9], [10], [11]. Usually, concentrations between 0.25 and 5 % are chosen according to type of lubricant, formulation and process parameters during tableting [10]. Downsides, especially of the most commonly used lubricant magnesium stearate, are the reduction of tensile strengths and the prolongation of disintegration and dissolution times [8], [12]. Susceptibility to the lubricant is dependent on many factors, one of them being the deformation mechanism of materials [13]. Plastically deformable materials are particularly sensitive to lubricants by lubricant film forming on the surfaces of the particles, weakening interparticle bondings and hence leading to lower tensile strengths of tablets. Brittle materials, on the other hand, create new, free surfaces for bondings through fragmentation [8], [12], [14], [15]. Studies have shown, that the choice of paddle speed in the feed frame has a high impact on the tensile strength of tablets, as the material in the feed frame is subject to shear forces and additional mixing prior filling into the dies [16], [17], [18]. In conclusion, the influence of a lubricant on tabletability depends on many factors, e.g. type and properties of the lubricant, other materials in the formulation and process parameters [8], [19].

An alternative to internal lubrication is the application of external lubrication, which means that the lubricant is sprayed onto the punch tooling and die walls. Several studies already dealt with this lubrication method [20], [21], [22], [23], [24], [25], [26], [27]. De Backere et al. conducted experiments on a compaction simulator and a rotary tablet press investigating different lubricants and process parameters. Low and comparable ejection forces were obtained for all lubricants. No detrimental effect on tensile strength was observed. Main compaction pressure was the only significant factor, while tableting speed and lubricant feed rate did not have an effect on tensile strength. Different lubricants led to comparable tensile strengths [21]. Jahn and Steffens optimized the spray rate of magnesium stearate by monitoring the ejection force in the tableting process of 4 different fillers and reduced the concentration of magnesium stearate to about 0.04 %, while no detrimental effect on tensile strength was observed [22]. Yamamura et al. reduced the amount of lubricant to 1/13 of that needed for internal lubrication to avoid sticking. Thereby, tensile strengths increased by 40 % compared to internal lubrication, disintegration times did not increase [25]. Another study indicated that spray rate, tableting speed and flow air volume of the dust collector have an impact for the magnesium stearate content on the tablets. Tablet strength and disintegration times of the tablets produced with use of external lubrication and different parameters were comparable. In general, externally lubricated tablets showed higher tablet strength and faster disintegration than internally lubricated tablets [23]. Zimmermann et al. showed the feasibility of external lubrication only by application of electrostatics without compressed air contrary to existing systems [25], [26]. Ejection forces could be decreased with magnesium stearate and tensile strengths were higher in comparison to internally lubricated tablets [26].

Coming back to mini-tablets, to date there have been hardly any systematic studies on the influence of external lubrication on mini-tablets. Uzondu et al. found that ejection force of tablets is affected by diameter and thickness of the tablet, the study however was performed with 10 mm tablets [9]. The study conducted by Kuck and Breitkreutz systematically evaluates the impact of lubrication on orodispersible tablets and mini-tablets with regard to ejection force, tensile strength and disintegration. Besides internal lubrication, external lubrication was also performed on a compaction simulator [28]. The study indicates that a higher amount of lubricant for mini-tablets is needed to sufficiently reduce the ejection force compared to conventionally sized tablets owing to the higher surface-to-volume ratio and the resulting greater friction at the die walls. External lubrication with magnesium stearate displayed adequate lubrication efficiency; strong tablets were produced, however prolonged disintegration times were observed for orodispersible mini-tablets [28].

To the best of our knowledge, up to now, no systematic studies on external lubrication of 2 mm mini-tablets on a rotary tablet press have been carried out. Two grades of silicified microcrystalline cellulose (SMCC 90 and 50) were chosen in this study in order to investigate possible variations in the same material but differing grades. SMCC is a co-processed excipient containing 98 % microcrystalline cellulose and 2 % silicon dioxide [29], [30], [31]. SMCC displays a five times greater specific surface than MCC alone which is ascribed to the high specific area of colloidal silicon dioxide [29], [31], [32], [33]. In literature, a mostly plastic deformation mechanism of SMCC is denoted [29], [34], [35], [36]. SMCC was already successfully used for formulation development of drug-loaded mini-tablets and also for further transfer and scale-up studies of drug-loaded mini-tablets with internal lubrication [37], [38]. Process parameters including tableting pressure, tableting speed, dosing rate and air pressure were evaluated with a special focus on the response tensile strength of mini-tablets.

Download the full article as PDF here A systematic investigation of external lubrication of mini-tablets on a rotary tablet press with focus on the tensile strength

or read it here

Materials

Silicified microcrystalline cellulose (PROSOLV® SMCC 90 and PROSOLV® SMCC 50, JRS Pharma, Rosenberg, Germany) and magnesium stearate (Parteck® LUB MST, Merck, Darmstadt, Germany) were used in this study.

Valentinë Lura, Stefan Klinken, Jörg Breitkreutz, A systematic investigation of external lubrication of mini-tablets on a rotary tablet press with focus on the tensile strength, European Journal of Pharmaceutics and Biopharmaceutics, 2024, 114236, ISSN 0939-6411, https://doi.org/10.1016/j.ejpb.2024.114236.

Read also our introduction article on Magnesium Stearate here: