Tailoring Dry Microparticles for Pulmonary Drug Delivery: Ultrasonic Spray Freeze-Drying with Mannitol and Salbutamol Sulphate

Abstract

Introduction

The pulmonary delivery of drugs is attracting widespread interest in the pharmaceutical field for the treatment of both respiratory and systemic diseases. The high targeting efficiency, low drug dose required, and huge alveolar surface area available for drug absorption represent the main striking features of inhalation therapy. Moreover, the therapeutic effectiveness of drugs is enhanced by pulmonary administration since first-pass metabolism is bypassed [1,2,3]. Both liquid and solid formulations are used for inhalation treatments, the former being delivered through nebulisers and pressurised metered-dose inhalers and the latter through dry powder inhalers (DPIs) [4]. Inhalable dry powders are emerging as the most advantageous formulation owing to their long-term stability and sterility [5,6]. However, an efficient drug deposition must be ensured to make pulmonary delivery effective [2,7]. Size, density, shape, and charge are the main factors affecting the deposition of particles in the lung, which also depends on their aerodynamic properties [8]. The key feature of these particles is their aerodynamic diameter (dae

), which is the diameter of a sphere with unitary mass density and the same settling velocity as the particle of interest [9]. In order to effectively reach the deepest regions of the lung, inhaled particles should possess dae

between 1 and 5 µm, ensuring optimal flowability [10,11].

The mass median aerodynamic diameter (MMAD) and geometric standard deviation (GSD) are commonly used to characterise a powder-based aerosol. MMAD defines the particle size with respect to which half of the powders is smaller and the other half is larger, while GSD quantifies the degree of variability of particle diameters with respect to the MMAD [4]. The efficiency of deposition is described by the fine particle fraction (FPF), which represents the fraction of particles with an aerodynamic size below 5 µm [12].

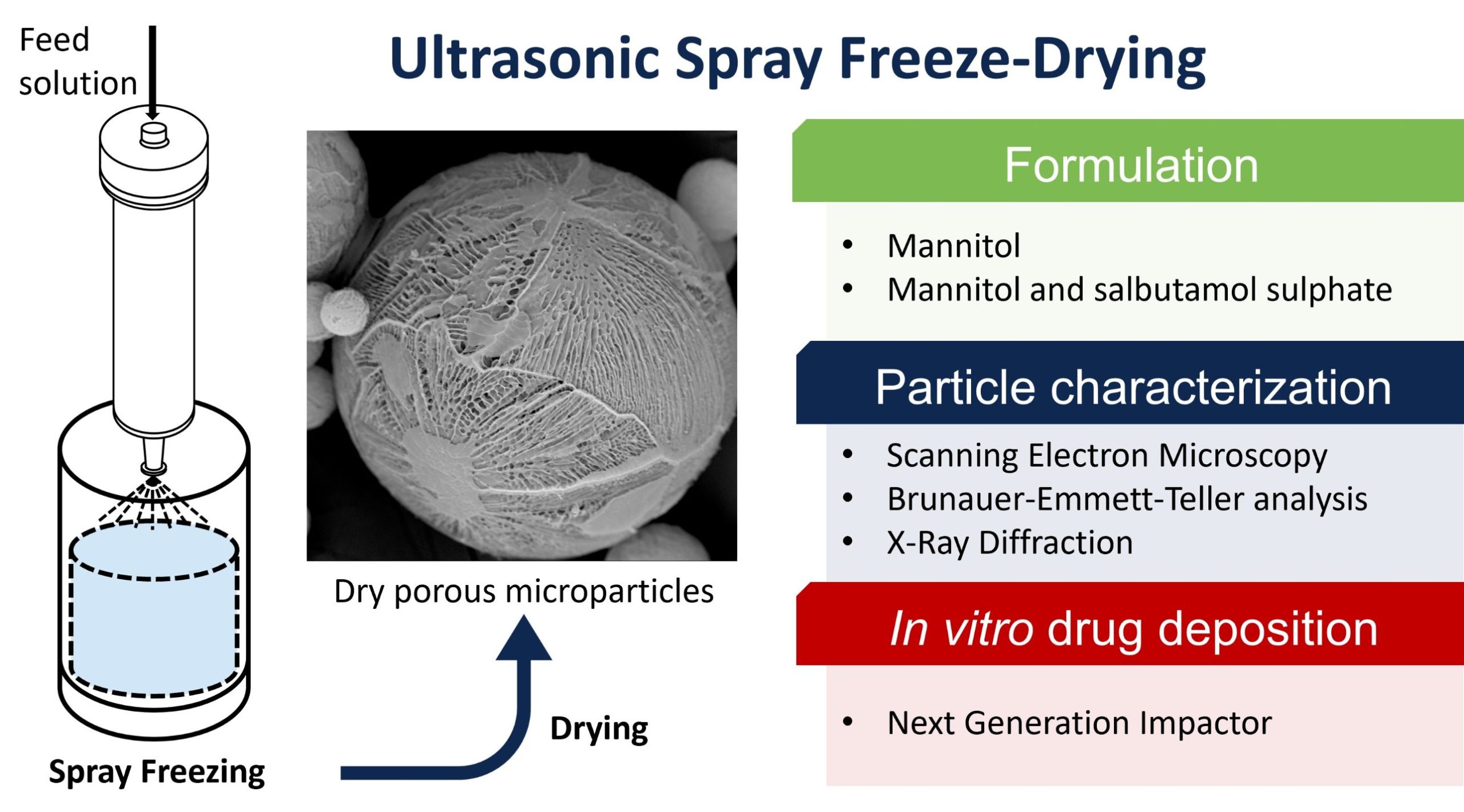

Inhalable fine powders can be produced by means of several techniques, including milling [13], spray-drying (SD) [14], spray freeze-drying (SFD) [15], thin film freezing [16], and supercritical fluid technology [17]. SFD is a promising approach consisting of three steps, i.e., atomisation, freezing, and drying [18]. During the first two stages, a solution of drug and excipients is fed to a nozzle, atomised in small droplets, and rapidly frozen using liquid nitrogen [19]. The atomisation step is responsible for the final particle size and shape [20] and can be performed by pneumatic [21] and ultrasonic [22,23] nozzles. Among the different types of atomisers, ultrasonic ones offer high control of size distribution and an efficient entrapment of particles in liquid nitrogen [24]. Freezing promotes the formation of ice crystals, which sublime during drying, giving the particles a porous structure [25]. The high porosity of spray freeze-dried particles allows for the reduction of particle density, dramatically improving the aerodynamic properties.

Additionally, SFD can be exploited to increase the dissolution of poorly water-soluble drugs owing to the high surface area of the final particles [26]. Various studies highlighted the superiority of SFD over SD for the generation of inhalable particles with unique aerosolization features and perfect spherical shape [27]. SFD can also be preferred to SD for thermolabile substances (i.e., biopharmaceuticals) since low temperatures are involved and thermal degradation is less likely to occur [28]. Moreover, the biomolecular structure is protected from phase separation since the crystallisation of excipients, solutes partitioning, and pH changes are reduced due to the high freezing rate [18,26,29,30]. Consequently, the drug is efficiently embedded into the excipient, increasing both the API bioavailability and the aerodynamic properties of particles [30]. Also, the excipient is well distributed into SFD particles owing to the limited diffusion of solute within droplets [31] [32].

SFD has been used in the formulation of different drugs for pulmonary delivery, including rizatriptan benzoate [29], voriconazole [33], cyclosporine A [32], clarithromycin [15], budesonide [34], proteins [22,35], and small interfering RNA [36]. This technique is especially suitable for generating carrier-free inhalable particles, an attractive formulation which does not require a coarse carrier (lactose) to have adequate flowability. Among these formulations, increasing interest has been given to large porous particles (LPPs), i.e., particles with low density (~

0.1 g/cm3) and large geometric diameter (5–30 µm), which possess outstanding aerodynamic performance and reduced macrophage uptake [37]. Although LPPs are commonly obtained by SD, the possibility of producing these particles via SFD has been explored [30].

In this work, porous microparticles (MPs) of mannitol were produced by ultrasonic SFD. Mannitol is one of the most-used excipients in SFD since it is easy to lyophilise and, having a high mannitol-ice eutectic temperature, the drying temperature can be increased without inducing macroscopic collapse [36,38]. Additionally, the formation of a crystalline mannitol structure during freezing enhances powders’ stability in DPIs [36]. This study aimed to comprehensively analyse SFD mannitol MPs, investigating the impact of the solid concentration and feed flow rate on MPs’ morphology, size, porosity, and crystallinity. The variation of such properties was also assessed upon the addition of salbutamol sulphate (SAS), a bronchodilator commonly used for the treatment of asthma. Furthermore, the aerodynamic behaviour of SAS-mannitol MPs was evaluated to assess their suitability for inhalation purposes. To the best of the authors’ knowledge, this study introduces for the first time the production of SAS-loaded MPs via ultrasonic SFD.

Download the full article as PDF here Tailoring Dry Microparticles for Pulmonary Drug Delivery: Ultrasonic Spray Freeze-Drying with Mannitol and Salbutamol Sulphate

or read it here

Pasero, L.; Susa, F.; Chiavarino, R.; Limongi, T.; Sulpizi, A.; Guidi, T.; Pisano, R. Tailoring Dry Microparticles for Pulmonary Drug Delivery: Ultrasonic Spray Freeze-Drying with Mannitol and Salbutamol Sulphate. Processes 2023, 11, 3096. https://doi.org/10.3390/pr11113096