Twin-Screw Melt Granulation with PEG 8000: effect of binder particle size and processing temperature on the granule and tablet properties

Introduction

- High-drug-loaded tablets and capsules are desirable and are manufactured using granulation as an additional step. Replacing batch wet granulation with twin-screw melt extruder as a continuous solventless process is gaining popularity. PEG 8000 being one of the most popular excipients used for melt granulation lacks thorough

investigation regarding its effect on the mechanical properties of tablets. Along with PEG 8000, a mixture of microcrystalline cellulose (MCC) and calcium phosphate anhydrous (CaHPO4 ) was chosen for granulation due to its unsatisfactory flowability. - The aim of this study was to investigate the effect of PEG 8000 particle size and twin-screw melt granulation temperature on the properties of resultant MCC-CaHPO4 granules and their tablets.

Materials

- MCC – CEOLUS UF-711 (Asahi Kasei, Japan); CaHPO4- DI-CAFOS A60 (Budenheim KG, Germany); PEG 8000 – Kollisolv® (BASF SE, Germany)

- Silica dioxide – SYLOID® 244FP (Grace GmbH, Germany) and Sodium stearyl fumarate – PRUV® (JRS Pharma, Germany) were used for directly compressed tablets (DC) where PEG 8000 was not used [ref.].

Methods

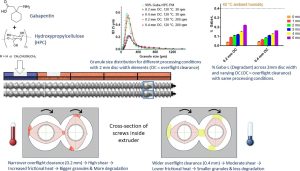

- Twin-Screw Melt Granulation was carried out using a Pharma 11 Extruder without nozzle, a Volumetric Mini Feeder, and a Conveyor (Thermo Electron CorporationGermany). The part of barrel that was used had a flighted length of 259 mm and a diameter of 11 mm with a length/diameter ratio (L/D) of 23.5:1. The screw design consisted of 1 L/D feed screw elements

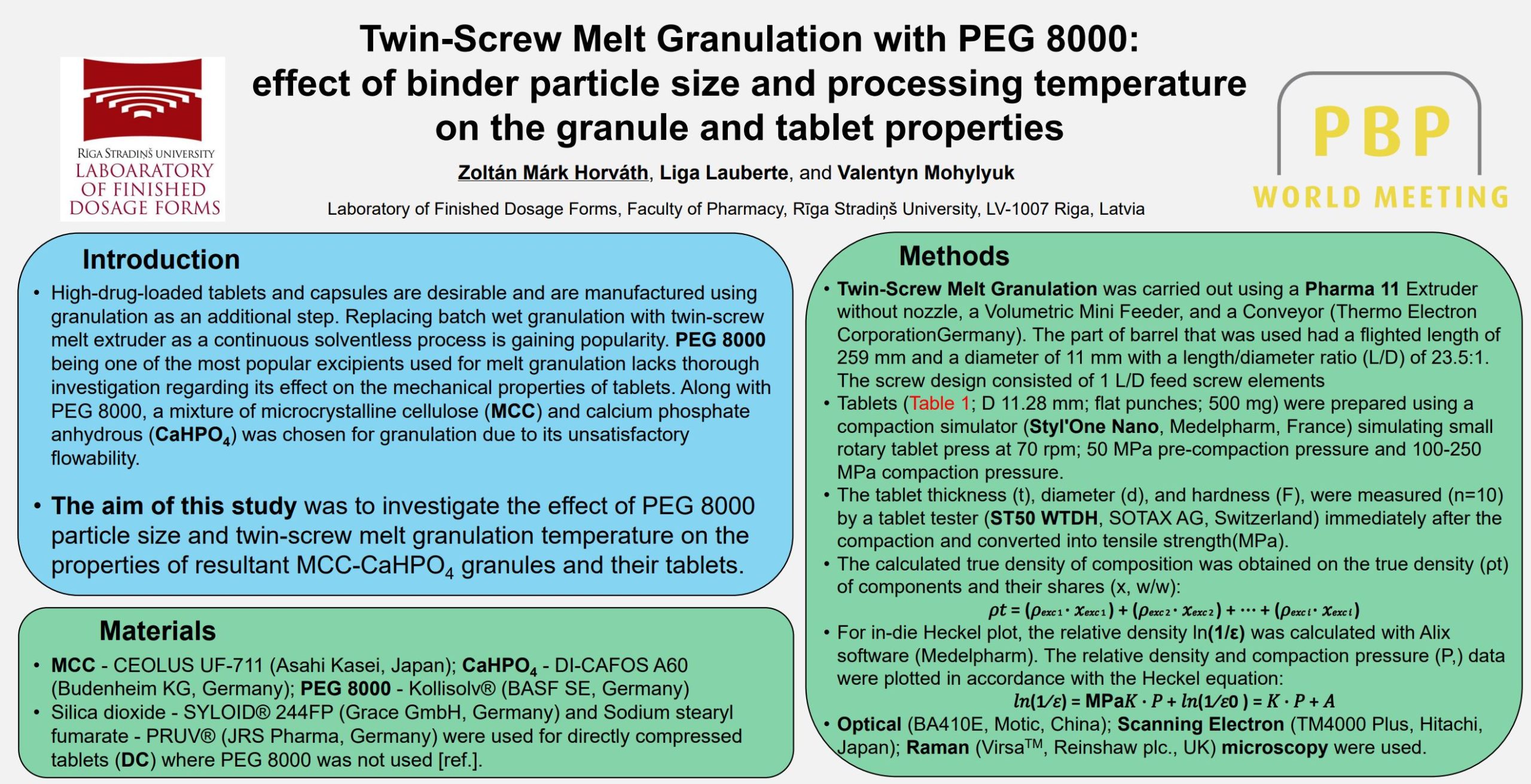

- Tablets (Table 1; D 11.28 mm; flat punches; 500 mg) were prepared using a compaction simulator (STYL’One Nano, MEDELPHARM, France) simulating small rotary tablet press at 70 rpm; 50 MPa pre-compaction pressure and 100-250 MPa compaction pressure.

- The tablet thickness (t), diameter (d), and hardness (F), were measured (n=10) by a tablet tester (ST50 WTDH, SOTAX AG, Switzerland) immediately after the compaction and converted into tensile strength(MPa).

- The calculated true density of composition was obtained on the true density (ρt) of components and their shares (x, w/w)

- For in-die Heckel plot, the relative density ln(1/ε) was calculated with Alix software (MEDELPHARM). The relative density and compaction pressure (P,) data were plotted in accordance with the Heckel equation

- Optical (BA410E, Motic, China); Scanning Electron (TM4000 Plus, Hitachi, Japan); Raman (Virsa TM, Reinshaw plc., UK) microscopy were used.

Results

- The size of granules increased with increasing PEG 8000 particle size and granulation temperature (Fig. 1)

- Optical microscopy of tablets revealed the individual granules and their points of contact (Fig. 2)

- Raman mapping (Fig. 3) confirmed the location of components and their conformation according to the optical microscope images in Fig. 2.

- CaHPO4 particles are surrounded by PEG 8000 coated MCC particles within tablets (Fig. 4).

- The plasticity of formulations increased with decreasing PEG 8000 particle size and with decreasing granulation temperature (Fig. 5).

- The plastic energy (Fig. 6) and tensile strength (Fig. 8) of formulations (up to 150 MPa) decreased with increasing PEG 8000 particle size and with increasing granulation temperature.

- The elastic energy of formulations increased with increasing PEG 8000 particle size and granulation temperature (Fig. 7).

- Compressibility decreased with increasing PEG 8000 particle size and with increasing granulation temperature (Fig. 9)

Discussion & Conclusion

- PEG 8000 particle size and granulation temperature influenced the granule’s properties (Fig. 1, 5-9)

- Structure of granules influenced formulation plasticity (Fig. 5)

- Structure of granules, their plasticity, and structure of tablets influenced their mechanical properties (Fig. 7-10).

- Most plastic formulations showed best tabletability profiles (Fig. 6, 8).

- Melt-granulated formulations showed lower tensile strength compared to ungranulated directly compressed tablets (Fig. 8)

Download the full poster on “Twin-Screw Melt Granulation with PEG 8000: effect of binder particle size and processing temperature on the granule and tablet properties” here

(click on the image to see them enlarged)

Source: PBP World Meeting, poster “Twin-Screw Melt Granulation with PEG 8000: effect of binder particle size and processing temperature on the granule and tablet properties”, Zoltán Márk Horváth, Liga Lauberte, and Valentyn Mohylyuk, Laboratory of Finished Dosage Forms, Faculty of Pharmacy, Rīga Stradiņš University, LV-1007 Riga, Latvia

Read also our other articles on Twin-Screw Melt Granulation here:

- Using twin-screw melt granulation to co-process mannitol and hydroxypropylcellulose

- Effect of Precirol ATO5 concentration and twin-screw melt granulation temperature on the physical properties of ascorbic acid granules

- Optimizing twin-screw melt granulation: The role of overflight clearance on granulation behavior

See more posters of the PBP World Meeting 2024: