Using twin-screw melt granulation to co-process mannitol and hydroxypropylcellulose

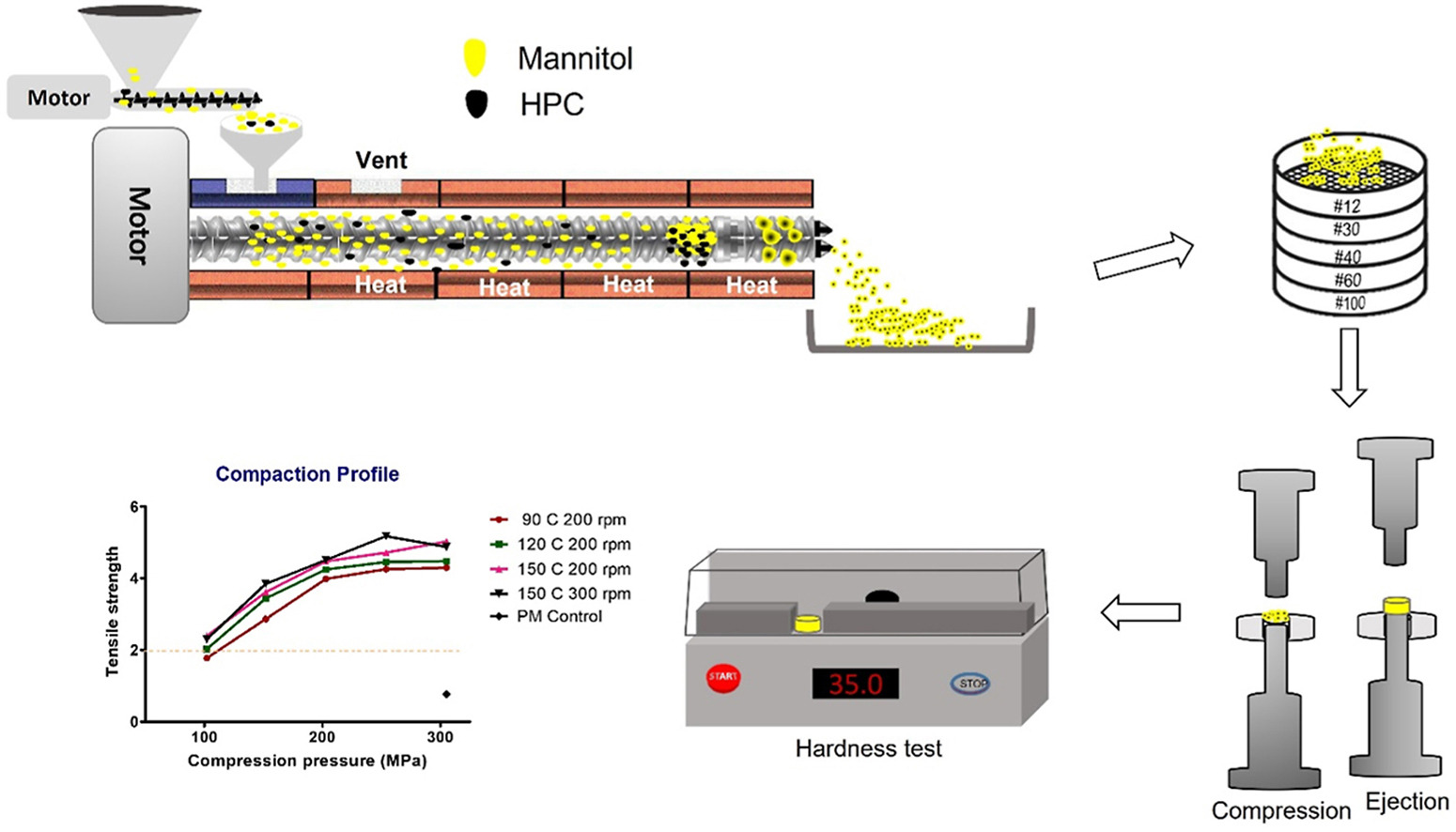

With the advent of continuous manufacturing, twin-screw melt granulation has attracted interest in the pharmaceutical industry as a method for co-processing excipients and developing new formulations. Twin-screw melt granulation relies on the heat and shear produced by the viscous and frictional heat dissipation generated by the rotating screws. The objective of this study is to explore the use of twin-screw melt granulation to co-process excipients in order to develop a new multifunctional excipient that improves the tabletability of mannitol. Binder level, barrel temperature, and screw speed are the main variables studied. Binder level (p < .05) has the most significant impact on the granule tabletability and the weight percentage of fines produced during granulation. Twin-screw melt granulation successfully co-processed mannitol and hydroxypropylcellulose (HPC), and a significant improvement in the tabletability of mannitol was observed at both 5% and 10% HPC levels. A 10% binder level was inferred to be the optimal level for a robust granulation process, and 5% was inferred to be feasible based on the tensile strength. A higher barrel temperature and a higher screw speed resulted in stronger granules. The optimal processing conditions were observed at a barrel temperature of 150 °C and a screw speed of 300 rpm. The tabletability of granules was evaluated against two different particle size fractions at the 10% HPC level. Fines (<150 μm) exhibited good tabletability as the tensile strength of all the compressed tablets exceeded the target of 2 MPa.

Adwait Pradhan, Mark Costello, Fengyuan Yang, Vivian Bi, Thomas Durig, Feng Zhang, Using twin-screw melt granulation to co-process mannitol and hydroxypropylcellulose, Journal of Drug Delivery Science and Technology,

2022, 103880, ISSN 1773-2247, https://doi.org/10.1016/j.jddst.2022.103880

See also Cellactose® a classic example of the above scenario because it is formulated by using spray drying to combine lactose (which is prone to fragmentation) with cellulose (the plastic component) to produce granules.

Read more about it here: