Compaction and Structural-Mechanical Properties of Tablets as a Function of Volume Ratios of Excipients

Introduction

- Using in tablet formulations microcrystalline cellulose (MCC) with plastic behaviour and calcium phosphate anhydrous (CaHPO4 ) with brittle behaviour under compaction is very popular in the pharmaceutical industry for achieving desirable structural-mechanical properties of tablets.

- The aim of this study was to investigate the compaction properties of mixtures of MCC and CaHPO4 in different volume ratios at the range of compaction pressure to observe and explain the influence of mixture composition on the structural-mechanical properties.

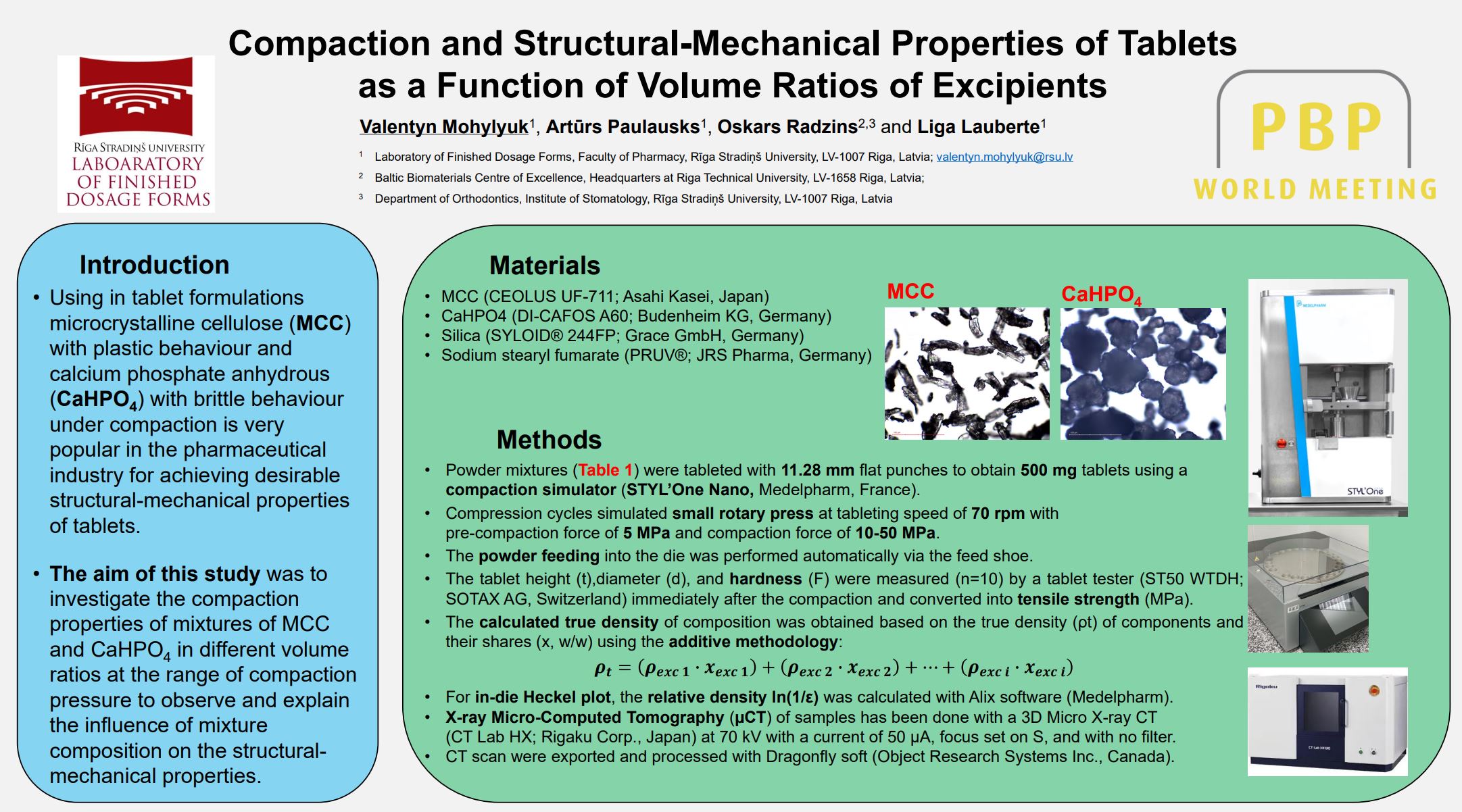

Materials

- MCC (CEOLUS UF-711; Asahi Kasei, Japan)

- CaHPO4 (DI-CAFOS A60; Budenheim KG, Germany)

- Silica (SYLOID® 244FP; Grace GmbH, Germany)

- Sodium stearyl fumarate (PRUV®; JRS Pharma, Germany)

Methods

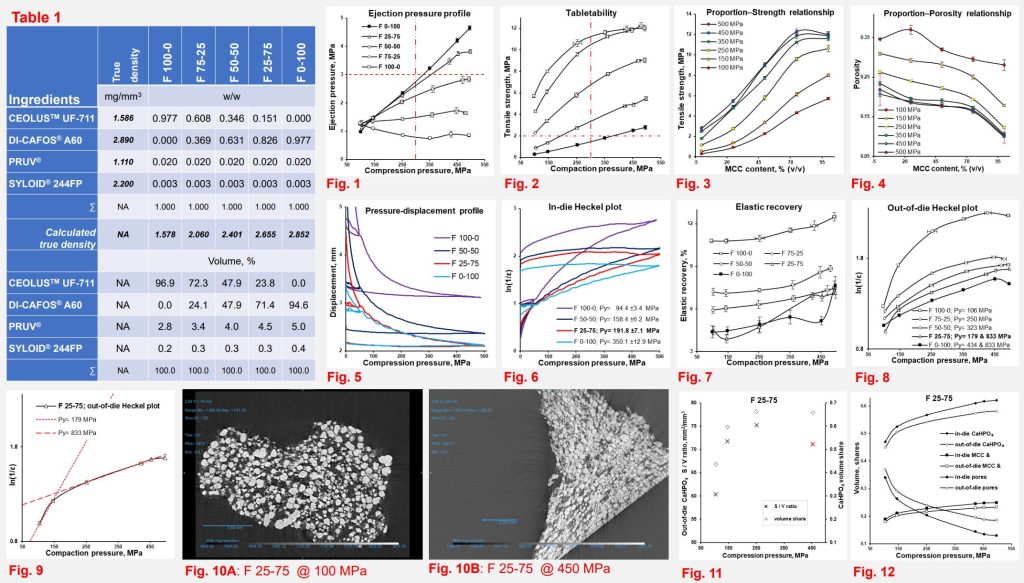

- Powder mixtures (Table 1) were tableted with 11.28 mm flat punches to obtain 500 mg tablets using a compaction simulator (STYL’One Nano, MEDELPHARM, France).

- Compression cycles simulated small rotary press at tableting speed of 70 rpm with pre-compaction force of 5 MPa and compaction force of 10-50 MPa.

- The powder feeding into the die was performed automatically via the feed shoe.

- The tablet height (t),diameter (d), and hardness (F) were measured (n=10) by a tablet tester (ST50 WTDH; SOTAX AG, Switzerland) immediately after the compaction and converted into tensile strength (MPa).

- The calculated true density of composition was obtained based on the true density (ρt) of components and their shares (x, w/w) using the additive methodology

- For in-die Heckel plot, the relative density ln(1/ε) was calculated with Alix software (MEDELPHARM).

- X-ray Micro-Computed Tomography (µCT) of samples has been done with a 3D Micro X-ray CT (CT Lab HX; Rigaku Corp., Japan) at 70 kV with a current of 50 µA, focus set on S, and with no filter.

- CT scan were exported and processed with Dragonfly soft (Object Research Systems Inc., Canada).

Results

- Lubricant amount was justified by the tablet ejection force profile (Fig. 1)

- Tensile strength increased along with MCC fraction and compaction pressure (Fig. 2)

- Proportion–tensile strength profiles in the 25-75 vol.% MCC range is almost linear (Fig. 3)

- Proportion–porosity profiles in the same 25-75 %vol. MCC range is almost linear (Fig. 4)

- Punches’ distance is smaller, tablets are thinner because of the true CaHPO4 density (Fig. 5)

- Increasing CaHPO4 portion has increased the in-die yield pressure – Py (Fig. 6)

- Increase in the MCC portion increased the value of elastic recovery (Fig. 7)

- Out-of-die was in line with in-die Heckel plot except for F25-75 (Fig. 8)

- Out-of-die Heckel plot of F25-75 at 100-150 and 150-500 MPa cause of MCC and CaHPO4 (Fig. 8-9)

- µCT 100 vs 450 MPa (Fig. 10); Comparison of processed µCT data (Fig. 11) vs. calculated (Fig. 12)

Discussion & Conclusion

- F100-0, F75-25 and F50-50 were in the Successful Formulation Window (Fig. 1-2)

- Non-linear segments can be related to the percolation threshold (Fig. 3-4)

- The plasticity and elastic recovery increase with increasing MCC (Fig. 6-8)

- F25-75 has the two-stage out-of-die Heckel plot (Fig. 8-9)

- 1st stage controlled by MCC and 2nd – by CaHPO4 (Fig. 8-9)

- µCT can be useful for de-formulation (Fig. 10-12)

Download the full poster on “Compaction and Structural-Mechanical Properties of Tablets as a Function of Volume Ratios of Excipients” here

(click on the image to see them enlarged)

Source: PBP World Meeting Poster “Compaction and Structural-Mechanical Properties of Tablets as a Function of Volume Ratios of Excipients” by Valentyn Mohylyuk 1, Artūrs Paulausks 1, Oskars Radzins 2,3 and Liga Lauberte 1

1 Laboratory of Finished Dosage Forms, Faculty of Pharmacy, Rīga Stradiņš University, LV-1007 Riga, Latvia; valentyn.mohylyuk[at]rsu.lv

2 Baltic Biomaterials Centre of Excellence, Headquarters at Riga Technical University, LV-1658 Riga, Latvia;

3 Department of Orthodontics, Institute of Stomatology, Rīga Stradiņš University, LV-1007 Riga, Latvia

Read also our articles on STYL’One Nano here:

- STYL’One Nano the revolutionary benchtop R&D tablet press

- Material characterization with an extended Dwell Time compression profile on STYL’ONE NANO

- Material characterization with a V-shape compression profile on STYL’ONE NANO

See more posters of the PBP World Meeting 2024: