How to Clean Sustained-Release Polymers

by Priya Poduval | July 22, 2020

Solubilizing SR excipients are difficult unless solvents are used for cleaning. Most of the companies using this method have a similar cleaning process – manual application using a lint-free wipe followed by vigorous scrubbing. Although this is effective, it is highly hazardous to the personnel, damaging to the equipment and should be avoided if a safe alternative is available.

The other cleaning procedure commonly employed is soaking of the residue in hot detergent solution (usually a detergent with high alkalinity), followed by manual scrubbing. Most often, the detergent neither dissolves / breaks down the residue or keep the soil suspended to avoid re-deposition. What it does do, is soften the residue, making it a bit easier to scrub off the equipment surface.

It is not possible to use one cleaner for all the Sustained Release excipients due to the multiple chemistries they have, which is why Chematic® has a range of customized solutions for safe and efficient cleaning of these residues. We could, however, group them into similar chemistries to minimize the number of detergents needed. Chematic® cleaners are effective in both manual and CIP/WIP (automated) applications.

Efficient Cleaning of SR polymers with Chematic® Cleaners

Euragit® SR polymers

Chematic®NE/NM & RL/RS Cleaners are specialty detergents that were developed in collaboration with Evonik for the removal of EUDRAGIT® NE 30 D, NM 30 D, NE 40 D & EUDRAGIT® RL/RS series respectively. These formulations readily penetrate and remove the multiple layers of product & polymer associated with the use of these formulations.

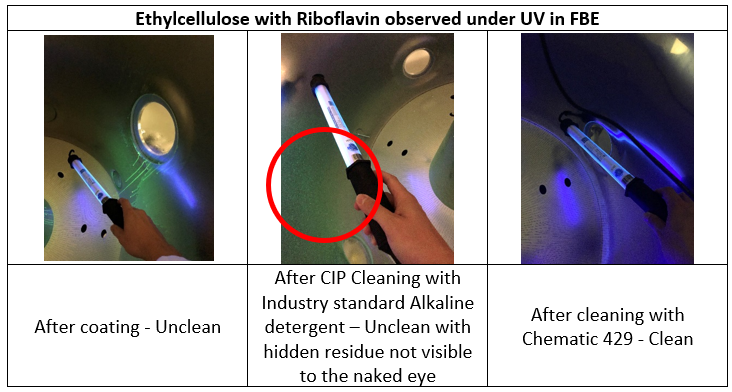

Ethylcellulose

Chemical cleaning of ethylcellulose can be done with either a solvent or a detergent specially designed to chemically breakdown & suspend the residue. We recently did a deep dive into How to Clean Ethylcellulose, be sure to check it out.

Poly (ethylene oxide) / Polyox

They are used in the granulation step for osmotic pump technology and matrix tablets. They are also used for mucoadhesive drug delivery dosage form. These powders are easily hydrated when hit with water, following which, cleaning is a challenging task. Depending on the molecular weight and other excipients, either Chematic® 422 or 429 detergents can be used to clean these polymers.

Cellulose Acetate

This polymer is mainly used for semipermeable coating on tablets, especially on osmotic pump-based tablets. Due to its limited solubility, cleaning is difficult, especially in the coating pan perforations. Chematic® 82 can be used to clean the residue without manual scrubbing even in equipment not having automated cleaning, using the fill, soak, and agitate method.

Shellac

Depending on its thickness, it could give an enteric or a sustained release profile. It could be used in granulation for matrix tablet or for coating. In recent years, shellac is being replaced by more efficient and robust polymers in Pharmaceutical industry, but it is still widely used in the Nutraceutical. Chematic® 1 has the capability to clean granulation as well as coating formulations containing shellac.

Recommended Procedure: Continue reading the article here to learn more about the recommended procedure. Article by Priya Poduval | July 22, 2020