Powders flowability assessment in granular compaction: What about the consistency of Hausner ratio?

In this study, powder flowability is assessed during granular compaction under free surface conditions by using Hausner ratio (HR) as flowability index. Different kinds of pharmaceutical and food powders were examined. The assessment of the flow properties of these powders according to HR is obtained using three compaction devices: DensiTap®, GranuPack® and a homemade Vibratory device (particle dumper).

Highlights

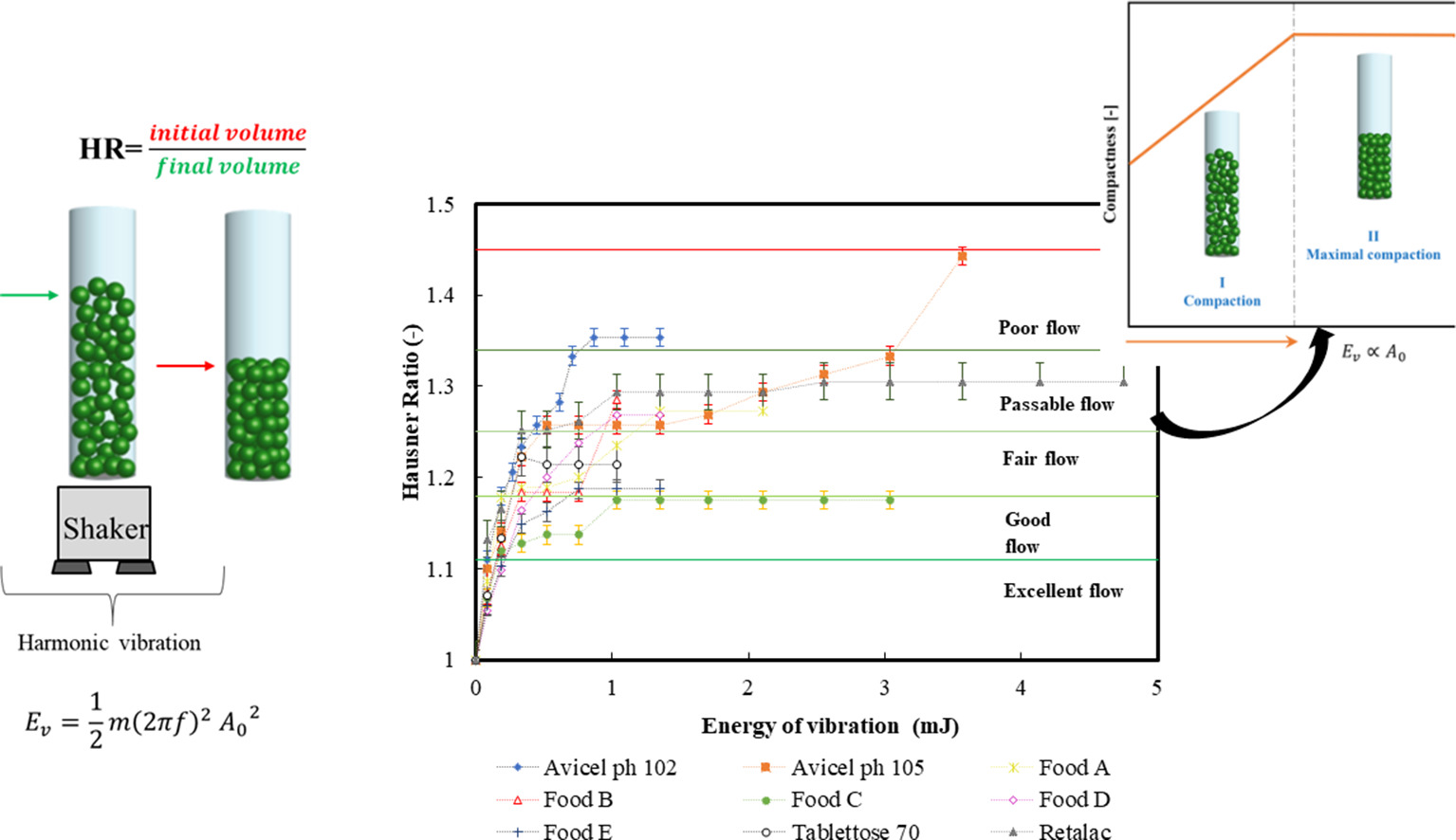

• HR and the energy provided to the powder system are closely related.• The energy provided to the system will allow, or not, grains maximal reorganization.

• A new HR obtained at maximal compaction state, HRU, is defined

The comparison of the HR values obtained with each compaction test provided a deeper understanding of HR. Here we show that HR is strongly dependent on the energy supplied to the system. This energy is the result of the vibration wave transmitted to the powder bed, and is strongly dependent on the vibration amplitude, i.e. on the device used.

HR analysis as a function of the energy supplied to the powder bed allowed us to determine a maximal HR value, denoted ultimate HR (HRU), obtained when reaching a maximal compaction state. Thus, a new approach is proposed to determine flow behavior, through HR, as a function of the energy supplied to the powder bed. More on powder flowability assessment in granular compaction

Materials

For the current study, nine powders samples have been selected according to their size distribution, particles shape and their flowbehavior observed with naked eye. Among them, two grades of lactose (L): Tablettose 70 and Retalac; two grades of microcrystalline cellulose (MCC): Avicel ph 102 and Avicel ph 105, and five commercial food powders (FP) denoted Food A, Food B, Food C, Food D and Food E respectively. The commercial name of the food powders is kept confidential.

Tablettose 70 is the trade name for α-lactose monohydrate produced by MEGGLE (Germany),which particles are characterized by a narrow size distribution. According to the technical brochure, Tablettose 70 is especially designed for direct-compression and exhibits a good flowability.

Retalac is lactose powder produced by MEGGLE (Germany), composed by equal parts of hypromellose polymer and α−lactose monohydrate. Retalac powders are characterized by excellent flow and compaction properties.

The two grades of Avicel, ph 102 and ph 105, produced by FMC Biopolymer, are high purity microcrystalline cellulose particles. Both powders differ only by their particles size distribution. Avicel ph grades are well known in the pharmaceutical industry for direct compression tableting applications.

A. Saker, M.-G. Cares-Pacheco, P. Marchal, V. Falk,

Powders flowability assessment in granular compaction: What about the consistency of Hausner ratio ?,

Powder Technology, Volume 354, 2019, Pages 52-63,

https://doi.org/10.1016/j.powtec.2019.05.032.