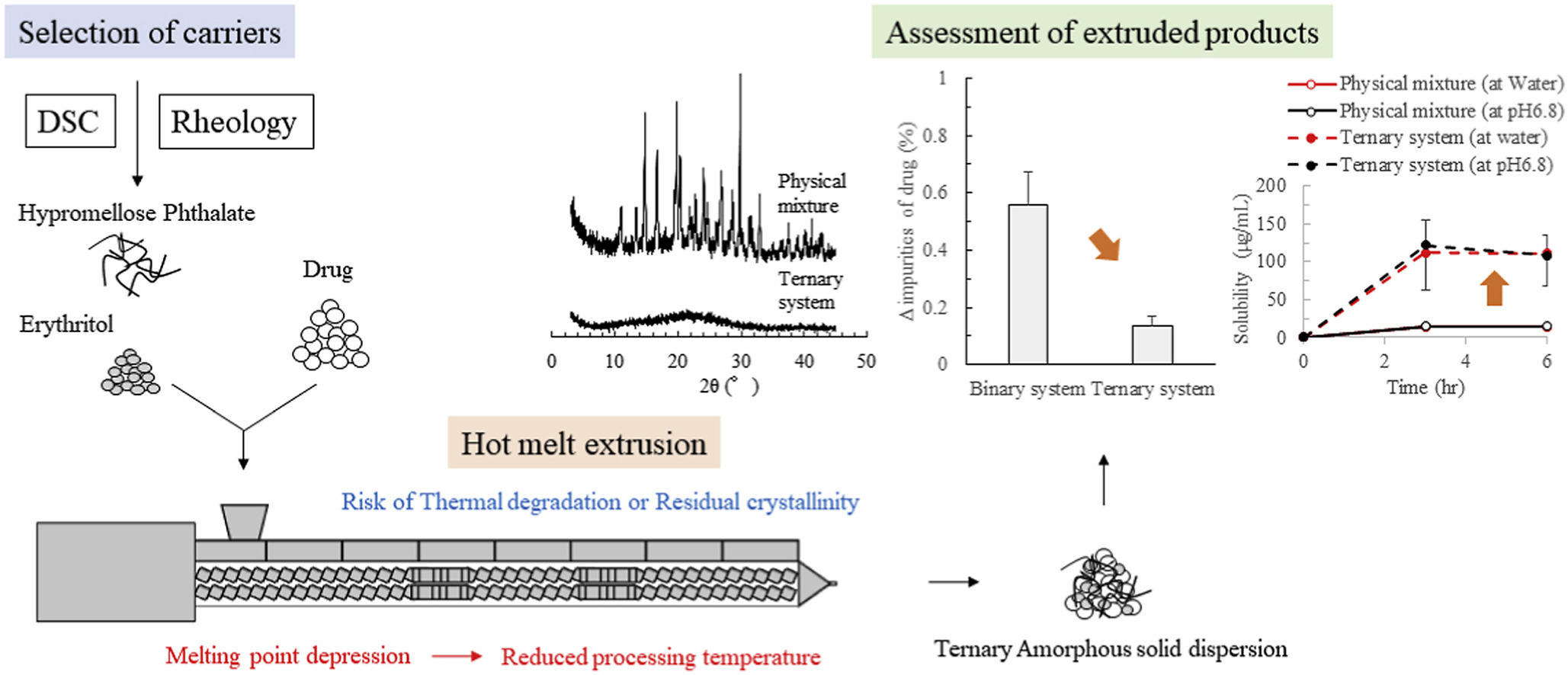

Characterization of ternary amorphous solid dispersion containing hypromellose phthalate and erythritol prepared by hot melt extrusion using melting point depression

Hot melt extrusion is a promising technology for producing amorphous solid dispersions, however, there is a risk of thermal degradation or residual crystallinity formation. This caveat may be addressed by optimizing formulations and manufacturing conditions. The aim of our study was to explore optimization of formulation by evaluating the thermodynamic and thermal rheological properties of griseofulvin mixed with various carriers, and to investigate the effects of the obtained system. The combination of griseofulvin with 14 varieties of polymers, 1 disaccharide or 4 varieties of sugar alcohols were analyzed using differential scanning calorimetry and rheology.

Our results indicated that melting point depression and thermal viscoelasticity were different between each of the formulations tested, and that a ternary system containing hypromellose phthalate (HP) and erythritol (Ery) allowed lowering of the processing temperature. Additionally, the rubber state of HP was maintained within a wide temperature range when mixed with Ery. A promising candidate formulation was manufactured using a twin screw extruder. All extruded products containing HP and Ery showed a reduction in thermal degradation. In addition, the products exhibited improved solubility and maintenance of supersaturated concentration when compared to crystalline griseofulvin, physical mixture or extruded products resulting from binary formulation with HP. Continue here

Keywords Twin screw extruder, Differential scanning calorimetry, Rheology, Thermal degradation, Residual crystallinity, Parteck, Parteck MXP, Kollidon VA64, Kollicoat IR, Pearitol 200SD, Xylisolb 700, Parteck SI, Carbopol 971PNF, Metolose SM-4