The Effect of Cellulose Nanofibers on the Manufacturing of Mini-Tablets by Direct Powder Compression

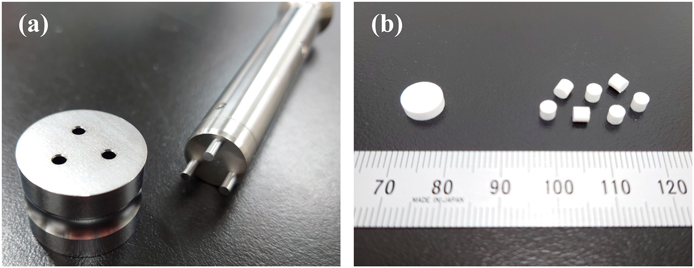

Mini-tablets (MTs) contain a small amount of active pharmaceutical ingredients in one small tablet. MTs are advantageous because they can be fine-tuned according to the age and weight of pediatric patients and they are easy for children and the elderly to swallow. However, there are manufacturing concerns such as the difficulty in achieving both hardness and disintegration of a small tablet and it is difficult to keep the tablet weight and drug content consistent in MTs because the mold used for its production is special. In this study, we aimed to determine if an additive such as cellulose nanofibers (CNF), which has been studied in various fields in recent years, could be used to manufacture MTs without difficulties. In this study, an MT was manufactured using a rotary tableting press with a compression force of 2, 5, and 8 kN, and the weight variation, drug content variation, tensile strength, friability, disintegration time, and drug dissolution were evaluated. Of note, the tensile strength of MTs produced with a compression force of ≥5 kN was ≥1.3 MPa, which was comparable to that of an ordinary tablet with an 8 mm diameter and a hardness of ≥30 N. The disintegration time of the MT which was 20–30% CNF was ≤30 s at any compression force. MTs with CNF showed similar disintegration to MTs with other common disintegrants. Therefore, we found that CNF is a functional additive capable of manufacturing MTs by direct powder compression which has both strength and disintegration.

Download the full article as PDF here The Effect of Cellulose Nanofibers on the Manufacturing of Mini-Tablets by Direct Powder Compression

or read it here

Materials

Lactose hydrate (Lac, diluent, Tablettose® 80, Meggle, Wasserburg, Germany), CNF (ELLEX-P (alcohol-containing type), disintegrant, Daio Paper Corp., Tokyo, Japan), acetaminophen (APAP, model drug, Tyco Healthcare Japan, Tokyo, Japan), and Mg-St (vegetable-based, lubricant, FUJIFILM Wako Pure Chemical Corporation, Osaka, Japan) were used for preparing the pharmaceutical powder. Microcrystalline cellulose (MCC, CEOLUS® KG-1000 , Asahi Kasei Corp., Tokyo, Japan), low-substituted hydroxypropyl cellulose (L-HPC, LH-21, Shin-Etsu Chemical Co., Ltd., Tokyo, Japan), crospovidone (CP, Kollidon® CL, BASF, Ludwigshafen, Germany), and croscarmellose sodium (CCS, KICCOLATE™ ND-2HS, Asahi Kasei Corp.) are commonly used additives, which were used as reference substances for CNF.

Shohei Nakamura, Mizuno Nakura, Takatoshi Sakamoto, The Effect of Cellulose Nanofibers on the Manufacturing of Mini-Tablets by Direct Powder Compression, 2022 Volume 70 Issue 9 Pages 628-636, https://doi.org/10.1248/cpb.c22-00290