Feasibility of In-line monitoring of critical coating quality attributes via OCT: Thickness, variability, film homogeneity and roughness

The feasibility of Optical Coherence Tomography (OCT) for in-line monitoring of pharmaceutical film coating processes has recently been demonstrated. OCT enables real-time acquisition of high-resolution cross-sectional images of coating layers and computation of coating thickness. In addition, coating quality attributes can be computed based on in-line data.

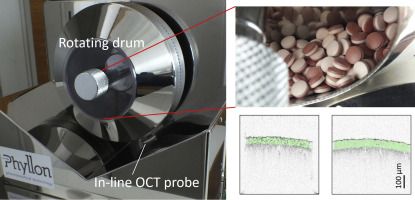

This study assesses the in-line applicability of OCT to various coating functionalities and formulations. Several types of commercial film-coated tablets containing the most common ingredients were investigated. To that end, the tablets were placed into a miniaturized perforated drum. An in-line OCT system was used to monitor the tablet bed. This set-up resembles the final stage of an industrial pan coating process. All investigated coatings were measured, and the coating thickness, homogeneity and roughness were computed.

The rotation rate was varied in a range comparable to large-scale coating operations, and no influence on the outcome was observed. The results indicate that OCT can be used to determine end-point and establish in-process control for a wide range of coating formulations. The real-time computation of coating homogeneity and roughness can support process optimization and formulation development.

Download the full article as a PDF here or read it here

Materials: Commercial tablets with different coating formulations were purchased in a standard pharmacy. In addition, three types of tablets were supplied by a pharmaceutical company (hereinafter referred to as Pharm 1, Pharm 2 and Pharm 3 rather than by the brand name). The coatings of the investigated tablets contain mostly common polymers and represent most types of coating functionalities, i.e., cosmetic, delayed release (enteric), extended release and osmotic-controlled release. The cosmetic coatings contained hydroxypropyl methylcellulose (HPMC) as a film-forming polymer, and the delayed release coatings were Eudragit-based. Both Eudragit L and Eudragit L30D are co-polymers of methacrylic acid with methyl acrylate and ethyl acrylate, respectively. The osmotic release coatings in this study contained HPMC and cellulose acetate (CA) as a polymer, and the extended release coating contained hydroxypropyl cellulose in addition. The coating of two types of tablets (Pantoloc and Pantoprazol) consisted of two separate layers, which may pose a challenge to the monitoring technique. Only tablets without or with a low amount of scattering pigments were selected, as high pigment contents is a limitation for OCT (Lin et al., 2017b). The tablets had round biconvex and oval biconvex shapes and sizes from 7 mm to 19 mm in diameter or length. Table 1 provides an overview of the investigated tablets and their most important coating ingredients. The dimensions were measured with a calliper. Note that pictures in the Table are not on the same scale.

More about OCT:

- How to measure coating thickness of tablets: Method comparison of optical coherence tomography, near-infrared spectroscopy and weight-, height- and diameter gain

- Measure coating thickness and characteristics in less than 2 minutes

- More on Phyllon

Article information: Stephan Sacher, Anna Peter, Johannes G. Khinast. Feasibility of In-line monitoring of critical coating quality attributes via OCT: Thickness, variability, film homogeneity and roughness, International Journal of Pharmaceutics: X, Volume 3, 2021. https://doi.org/10.1016/j.ijpx.2020.100067.

Get more Information on OSEET by Phyllon