Understanding the impact of mannitol on physical stability and aerosolization of spray-dried protein powders for inhalation

Abstract

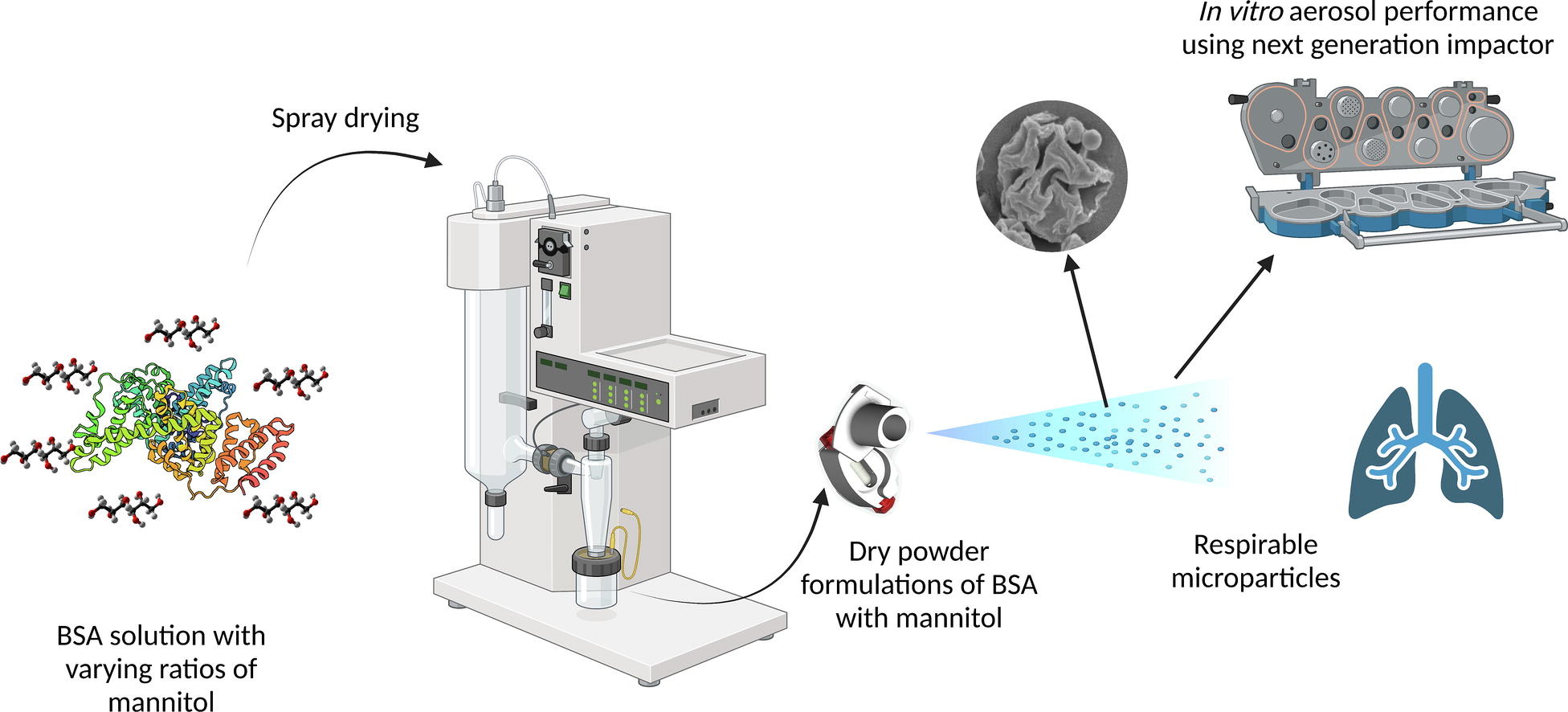

Pulmonary delivery of protein-based therapeutics, including antibodies, is a promising option for treating respiratory diseases. Spray drying is a widely used method for producing dry powder formulations with mannitol being a commonly used excipient for these inhalation formulations. There is limited research available concerning the utilization of mannitol as an excipient in the spray drying of proteins and its impact on aerosol performance. This study highlights the importance to understand mannitol’s potential role and impact in this context. To investigate the impact of mannitol on physical stability and aerosolization of spray-dried protein formulations, Bovine Serum Albumin (BSA) was employed as a model protein and formulated with different concentrations of mannitol via spray drying. The spray-dried solids were characterized for their particle size using Malvern Mastersizer and aerodynamic particle size using Next Generation Impactor (NGI). Additionally, the solids were characterized with solid-state Fourier-transform infrared spectroscopy (ssFTIR), powder X-ray diffraction (PXRD), scanning electron microscopy (SEM) and ssNMR to analyze the change in their secondary structure, crystallinity, particle morphology, and protein-excipient interaction, respectively. Size exclusion chromatography (SEC) was used to investigate changes in monomer content resulting from storage under the stressed condition of 40°C. Protein formulations containing more than 33% mannitol by weight showed crystallization tendency, causing an increase in monomer loss over time. ssNMR data also showed mixing heterogeneity of BSA and mannitol in the formulations with high mannitol contents. Fine Particle Fraction (FPF) was also found to decrease over time for the formulations containing BSA: Mannitol in the ratios of 2:1, 1:2, and 1:5, due to particle agglomeration induced by crystallization of mannitol. This study underscores the significant influence of excipients such as mannitol on the aerosol performance and storage stability of spray-dried protein formulations.

Introduction

Biopharmaceuticals, especially, protein therapeutics have seen a rapid growth in recent years (Chang et al., 2021). Delivery of protein therapeutics is often accompanied with a number of challenges due to their complex nature with large molecular size, making them prone to physical and chemical degradations (Mitragotri et al., 2014). Proteins have high molecular mass and limited ability to permeate biological barriers, such as skin and mucosal membranes (Chang et al., 2021, Mitragotri et al., 2014). Oral delivery of protein therapeutics is difficult to achieve with the presence of high activity of proteolytic enzymes in the gastrointestinal tract. Therefore, protein therapeutics are commonly delivered via the invasive parenteral route.

Pulmonary delivery serves as a non-invasive alternative to the parenteral route and is commonly employed in the treatment of various respiratory diseases (Chang et al., 2021). Low proteolytic enzyme activity in the lungs makes the pulmonary route a promising option for the delivery of protein therapeutics (Depreter et al., 2013). In addition, pulmonary delivery offers targeted delivery of therapeutics with reduced systemic side effects (Liang et al., 2020). Multiple devices are available for inhalation products, including dry powder inhalers (DPIs), pressurized metered dose inhalers (pMDIs), soft mist inhalers and nebulizers (Zhou, 2014). DPIs have attracted increasing attention for delivering biologics, since they offer several advantages as compared to solution formulations. Dry powder protein formulations have enhanced stability than their liquid counterparts, ensuring preservation of their biological activity and effectiveness with longer shelf-life (Chaurasiya and Zhao, 2020). Furthermore, DPIs are easier to carry and use as compared to nebulizers. In addition, DPIs enable rapid self-administration without professional supervision (Chang et al., 2021, Chung et al., 2012).

Several techniques are employed for manufacturing solid protein formulations that could be administered using DPIs. Lyophilization is a commonly used technique for producing solid dosage forms of biologic products with the goal of preserving protein structure and prolonging shelf-life; however, it has limitations, such as low drying efficiency and extended drying times (Kasper et al., 2013). Additionally, lyophilization produces a cake-shape products instead of particles or powders, which require further processing such as milling to generate inhalable particles; however, milling can introduce extra mechanical stresses on proteins and cause instability issues (Patel, 2017). This highlights the necessity for alternative drying methods that can enhance efficiency and yield particles suitable for inhalation. Traditional jet milling may not be a viable technique for producing the DPI formulation of proteins due to its potential to cause mechanical and thermal damage to the biological products (Cun et al., 2021). Alternatively, particle engineering techniques such as spray drying and spray freeze drying have been employed to generate biological particles with properties suitable for inhalation (Cun et al., 2021).

Spray-drying is a widely used technique for production of dry power dosage forms for inhaled drug delivery (Fernandes, 2022). It allows particle engineering of the dried solids with desired features such as certain particle size range, shape, and surface morphology contributing to aerodynamic properties suitable for inhalation (Ameri and Maa, 2006, Carrigy et al., 2019). Inhalation products containing small molecule drugs such as tobramycin (in TOBI® Podhaler™), and therapeutic biologics, such as Exubera (inhaled insulin) and Raplixa (fibrin sealant) have been successfully manufactured using spray drying. However, the exposure of protein molecules to thermal and shear stresses during the spray-drying process raises concerns about the stability of spray-dried protein solids, making it crucial to investigate stability during drying and storage (Chen et al., 2021, Mutukuri, 2021). Excipients such as sugars are added into the protein formulations to improve their physical stability by hydrogen bonding with proteins or maintaining their amorphous state to decrease matrix mobility (Mensink et al., 2017). Sugars such as trehalose and sucrose are commonly used to stabilize protein solids, however, they are hydroscopic after drying and can induce particle agglomeration. (Chen et al., 2021)

Mannitol is a commonly used excipient used in inhaled pharmaceuticals. It has been reported to offer an enhanced aerosol performance when added into the DPI formulations for spray drying or spray freeze drying processes (Adi et al., 2010, Malamatari et al., 2016). Previous studies performed in our lab indicated that, the presence of crystalline mannitol in the spray-dried protein solid formulation may lead to physical instability of the protein (Chen et al., 2021). There is a lack of study that systematically examines the impact of different protein to mannitol ratios on the solid-state properties of spray-dried protein solids, the change in storage stability, and its impact on aerosol performance. This study focuses on understanding the effects of varied mannitol ratios on storage stability and aerodynamic performance of spray-dried protein formulations.

Read more here

Materials

Bovine serum albumin (BSA), a lyophilized powder (>98%) and D-mannitol were purchased from Sigma Aldrich (St. Louis, MO). Monobasic sodium phosphate, dibasic sodium phosphate heptahydrate, monobasic potassium phosphate, dibasic potassium phosphate and sodium hydroxide were purchased from Sigma Aldrich (St. Louis, MO). Phosphoric acid (85%) was used to adjust the pH of buffer solutions to 6.8 and was obtained from Thermo Scientific

Kinnari S Arte, Cole W Tower, Tarun T Mutukuri, Yuan Chen, Sajal M Patel, Eric J Munson, Qi Tony Zhou,

Understanding the impact of mannitol on physical stability and aerosolization of spray-dried protein powders for inhalation, International Journal of Pharmaceutics, 2023, 123698, ISSN 0378-5173, https://doi.org/10.1016/j.ijpharm.2023.123698.

Get more information on our free webinar “Spray drying with Shin-Etsu, ProCepT and Xedev” here: