Polymeric Drug Delivery Systems by Additive Manufacturing

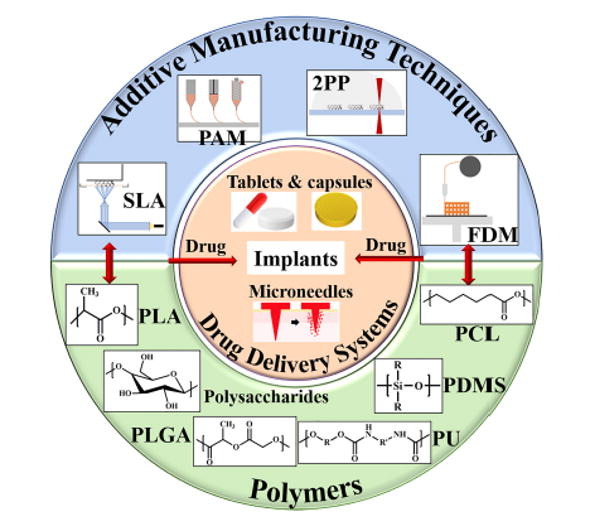

Additive manufacturing (AM) is gaining interests in drug delivery applications, offering innovative opportunities for the design and development of systems with complex geometry and programmed controlled release profile. In addition, polymer-based drug delivery systems can improve drug safety and efficacy and patient compliance and are the key materials in AM. Therefore, combining AM and polymers can be beneficial to overcome the existing limitations in the development of controlled release drug delivery systems. Considering these advantages, here we are focusing on the recent developments in the field of polymeric drug delivery systems prepared by AM.

This review provides a comprehensive overview on a holistic polymer–AM perspective for drug delivery systems with discussion on the materials, properties, design and fabrication techniques and the mechanisms used to achieve a controlled release system. The current challenges and future perspectives for personalized medicine and clinical use of these systems are also briefly discussed.

Download the full article as a PDF here or read it here

Article information: Sedigheh Borandeh, Bas van Bochove, Arun Teotia, Jukka Seppälä. Advanced Drug Delivery Reviews, 2021. https://doi.org/10.1016/j.addr.2021.03.022.

Read the first parts of the introduction here:

A drug delivery system can be defined as a method or process using the principles of chemistry, engineering and biology for administering of pharmaceutical compounds with high therapeutic effects. Currently, there are high demands for designing modified release drug delivery systems for reducing frequency of dosing and increasing the efficiency of the drug at the required site to minimize its side effects [1], [2]. Until now, considerable advances have been made in the development of different sustained and controlled drug delivery systems based on polymers [3], [4]. Advancement of drug delivery systems have been significantly achieved by using polymers, enabling both hydrophilic and hydrophobic drugs to be delivered over an extended period of time to the site of action [5]. Improved drug safety and efficacy and patient compliance can be obtained using polymer-based drug delivery systems. These systems are designed to keep the therapeutic levels of the drug, reduce the side-effects and drug dosage, and to facilitate the delivery of drugs with short in vivo half-lives [6].

Several methods have already been used for providing sustained or controlled release polymeric drug delivery systems, such as polymer encapsulation and polymer bound drug systems [4], [7]. However, there is still a need towards developing more controlled and even tailored release profiles. Layer-by-layer additive manufacturing (AM) techniques enable rapid production of novel personalized drug delivery systems, where conventional manufacturing is impractical due to cost and design limitations. AM is one of the emerging megatrends that has progressed remarkably in the last few years. With the ability of mass customization, on demand supply, individualized dosing, and flexibility with drug combinations, AM offers great potential for the pharmaceutical sector. Through AM, various drug delivery systems can be fabricated with several predesigned sizes, shapes, material and drug combinations [8], [9], [10].

Download the full article as a PDF here or read it here

Materials: Polyvinylalcohol (PVA), Ethylcellulose (EC), HPC, HPMC, EVA, PU